Fatigue tester for Elastic fabric

$0.00

Fatigue Tester for Elastic Fabric

Fatigue tester for Elastic fabric

A Fatigue Tester for Elastic Fabric is a specialized instrument designed to evaluate the durability and performance of elastic materials, such as elastic bands, tapes, and fabrics, under repeated stretching and relaxation cycles. This testing is crucial for applications where elastic materials are subjected to continuous or repetitive stress, ensuring they maintain their functionality over time.

Purpose Fatigue Tester for Elastic Fabric The primary objective of this tester is to simulate the conditions that elastic fabrics endure during actual use. By repeatedly stretching and relaxing the material, the tester assesses:

– Elastic Recovery: The ability of the material to return to its original length after stretching.

– Fatigue Resistance: How well the material withstands repeated cycles without significant degradation.

– Durability: The lifespan of the elastic properties under continuous use.

Working Principle of Fatigue Tester for Elastic Fabric

The tester operates by clamping a specimen of the elastic fabric and subjecting it to cyclic stretching and relaxation.

Key operational features include:

Cycle Count: The number of stretching and relaxation cycles is set according to testing requirements.

– Speed Regulation: The rate of stretching can be adjusted to simulate different usage conditions.

– Monitoring: The tester records data such as the number of cycles completed and any changes in the fabric’s properties.

For instance, the Elastic Band Fatigue Tester ADL-FT01 features a high-speed linear slide, servo motor, and touch screen control software, allowing precise control over stretching parameters

Key Specifications of Fatigue Tester for Elastic Fabric

While specifications may vary among different models, common parameters include:

– Stretch Percentage: Adjustable from 0% to 100%.

– Stretching Speed: Up to 40 cycles per minute.

– Sample Length Range: Maximum of 260mm.

– Cycle Count Capacity: Up to 9,999,999 cycles.

– Control Interface: Typically a 7-inch color touch screen.

– Power Supply: AC220V 50Hz/60Hz.

These features enable comprehensive testing of elastic materials under various conditions.

Benefits of Fatigue Tester for Elastic Fabric

– Quality Assurance: Ensures that elastic materials meet required durability standards.

– Product Development: Aids in the design of materials with improved fatigue resistance.

Cost Efficiency: Identifies potential material failures early, reducing product returns and warranty claims.

– Compliance: Helps manufacturers adhere to industry standards such as GB/T 37635.

Applications of Fatigue Tester for Elastic Fabric

Fatigue testers for elastic fabrics are widely used in:

– Textile Manufacturing: Testing elastic components in garments, such as waistbands and cuffs.

– Medical Textiles: Evaluating the durability of elastic materials used in bandages and supports.

– Automotive Industry: Assessing elastic components in car interiors.

– Research and Development: Developing new elastic materials with enhanced properties.

Features of Fatigue Tester for Elastic Fabric:

- Adjustable Stretch Range – Allows setting stretch levels (e.g., 0–100%) to simulate real-life fabric use.

- High-Cycle Capability – Supports up to millions of stretch-relax cycles for long-term fatigue analysis.

- Touch Screen Control – 7-inch color display for easy setup, monitoring, and data entry.

- Servo Motor Driven – Ensures precise and smooth linear motion during testing.

- Customizable Speed – Adjustable test speed (e.g., up to 40 cycles per minute) based on test requirements.

- Multi-Sample Testing – Some models allow testing multiple specimens simultaneously.

- Cycle Counter with Alarm – Built-in counter with programmable stop after preset cycles and auto-alert feature.

- Durable Construction – Robust metal frame suitable for continuous testing in lab environments.

- Standard Compliance – Designed to follow standards like GB/T 37635 for elastic fabric testing.

How to Use Fatigue Tester for Elastic Fabric:

- Prepare the Sample

– Cut the elastic fabric to the specified size (e.g., 260 mm max length).

– Mark the gauge length if needed for measurement after testing.

- Mount the Sample – Secure both ends of the fabric in the upper and lower clamps.

- Set Test Parameters

– Enter the desired stretch percentage (e.g., 50%).

– Set the number of cycles and speed (e.g., 30 cycles/min).

– Adjust dwell time if required (time fabric stays stretched).

- Start the Test – Press start on the touch screen interface. – The machine will cyclically stretch and release the sample.

- Monitor Progress – Observe operation or let it run automatically.

– Machine stops automatically after reaching the set cycles.

- Remove and inspect – Take out the fabric and measure elongation, recovery, or visual defects.

- Record and Compare Results – Compare with initial measurements or standard performance criteria.

Fatigue tester for Elastic fabric

Related products

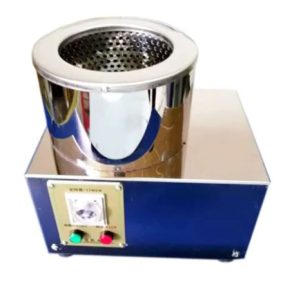

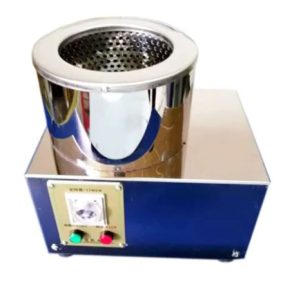

Laboratory hydro Extractor

Laboratory Hydro Extractor

A Laboratory Hydro Extractor is a compact, high-speed centrifuge used in textile labs to remove excess water from fabric or yarn samples after dyeing or washing. It works on the principle of centrifugal force, efficiently reducing moisture content before drying. Key Features:- Centrifugal Water Extraction - Uses high-speed spinning (typically 1400–2800 RPM) to extract water from textiles.

- Stainless Steel Inner Basket - Perforated drum holds fabric/yarn securely and allows water to drain efficiently.

- Compact Lab Design - Space-saving unit designed specifically for laboratory sample sizes.

- Digital Timer and Speed Control - Allows precise setting of spin duration and RPM to match sample needs.

- Safety Lock System - Ensures the lid remains closed during operation for user safety.

- Quick Water Removal - Significantly reduces drying time by extracting up to 90–95% of water content.

- Low Noise and Vibration - Balanced design ensures quiet and stable operation.

- Efficient Water Removal - Rapidly extracts 90–95% of water from samples, reducing drying time significantly.

- Saves Time and Energy - Cuts down the load on dryers and shortens total processing time in lab workflows.

- Improves Sample Quality - Gentle spinning preserves fabric structure, avoiding damage or distortion.

- Precise Control - Adjustable speed and timer ensure optimal settings for different fabric types.

- Compact and Lab-Friendly - Small footprint ideal for laboratory use with limited space.

- User Safety - Safety lock prevents lid opening during operation, protecting the user.

- Cost-Effective - Reduces the need for extended dryer use, saving on electricity and equipment wear.

- Versatile Use - Suitable for yarn, fabric, and garment samples across various fiber types.

- High-Speed Centrifugal Operation - Typically runs at 1400–2800 RPM for quick and efficient water removal.

- Stainless Steel Inner Drum - Corrosion-resistant, perforated basket for durability and efficient water drainage.

- Digital Timer and Speed Control - Allows precise control of spin duration and speed based on sample type.

- Compact and Portable Design - Ideal for lab environments with limited space.

- Safety Lock Mechanism - Prevents the lid from opening while the machine is in operation.

- Shock Absorption System- Reduces vibration and noise for smooth, stable performance.

- Quick Cycle Times - Short dewatering cycles improve lab throughput and efficiency.

- Low Maintenance Design - Simple mechanical setup with easy-to-clean components.

- Sample Versatility - Suitable for small fabric swatches, yarns, and small garments.

- Energy Efficient - Uses minimal power while delivering high performance.

- Prepare the Sample - After dyeing or washing, gently squeeze excess water from the fabric or yarn sample by hand.

- Load the Sample - Open the lid and place the sample evenly in the stainless steel drum. - Avoid overloading or uneven placement to maintain balance.

- Close the Lid securely - Ensure the safety lid is properly closed and locked.

- Set the Timer and Speed - Use the control panel to set the spin time (typically 1–5 minutes) and RPM suitable for the sample type.

- Start the Machine- Press the start button. The extractor will spin at the selected speed to remove water via centrifugal force.

- Wait for Spin Completion - The machine will automatically stop after the timer runs out.

- Unload the Sample - Once the drum stops completely, open the lid and carefully remove the sample.

- Proceed to Drying - The dewatered sample can now be air-dried or placed in a drying oven or stenter.

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Laboratory hydro Extractor Machine Dunlin price in Bangladesh Laboratory hydro Extractor Machine Dunlin in textile Textile testing equipment in Bangladesh Textile testing equipment in Dhaka Textile testing equipment in Uttara MAAM tex Laboratory hydro Extractor Machine Dunlin price in Bangladesh

Laboratory hydro ExtractorBursting strength tester

Bursting strength tester

true burst

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

- Bursting pressure can reach up to 1.2MPa 5. The maximum burst and expansion degree can reach 70mm. 6. Strengthen the lighting system on the test surface. 7. The main aerodynamic force helps to clamp the sample system. 8. A variety of test areas are available, and the switching is easy.

- A variety of unit conversions between Chinese and English. 10. Reliable anti-pinch safety protection design. [Technical parameter]: 1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized) 2. The minimum graduation value: 0.0001Mpa 3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree pressurization.

Oscillation type water bath Dyeing Machine

Oscillation Type Water Bath Dyeing Machine

An Oscillation Type Water Bath Dyeing Machine is a laboratory apparatus designed for dyeing and washing textile samples under controlled temperature conditions. It combines a heated water bath with an oscillating mechanism to ensure uniform dye penetration and consistent coloration across fabric or yarn samples. Key Features of Oscillation Type Water Bath Dyeing Machine - Oscillating Mechanism: Provides back-and-forth movement to agitate the dye solution, ensuring even contact between the dye and the textile sample.- Multiple Beaker Capacity: Typically accommodates 12 to 24 beakers, allowing simultaneous processing of multiple samples under identical or varied conditions. - Digital Temperature Control: Maintains precise temperature settings, usually up to 99°C, suitable for various dyeing processes including atmospheric dyeing, scouring, and bleaching.- Adjustable Oscillation Speed: Offers variable speed settings, commonly ranging from 50 to 200 cycles per minute, to accommodate different fabric types and dyeing requirements. - Programmable Settings: Advanced models come with programmable controllers, allowing users to set and save multiple dyeing protocols for repeatability and efficiency. Durable Construction: Constructed with high-quality stainless steel (e.g., SUS304), ensuring resistance to corrosion and longevity even under rigorous laboratory conditions. ✅ Benefits of Oscillation Type Water Bath Dyeing Machine - Uniform Dyeing Results: The oscillation mechanism ensures consistent dye penetration, reducing the risk of uneven coloration and enhancing the reproducibility of results.- Efficiency in Sample Processing: The ability to process multiple samples simultaneously accelerates laboratory workflows and facilitates comparative studies. - Versatility: Suitable for a range of applications including dyeing, washing, scouring, bleaching, and fastness testing across various textile materials.- Energy and Resource Conservation: Designed for low liquor ratios (e.g., 1:5 to 1:20), these machines minimize water and chemical usage, promoting sustainable laboratory practices. - Enhanced Safety and Cleanliness: Enclosed beaker systems reduce the risk of spills and exposure to chemicals, ensuring a safer laboratory environment. Typical Applications of Oscillation Type Water Bath Dyeing Machine - Textile Research and Development: Ideal for developing and testing new dye formulations and processes on a small scale before scaling up to production levels. Quality Control: Used in quality assurance laboratories to assess color fastness, dye uptake, and other critical parameters of textile products.- Educational Purposes: Serves as a practical tool in academic settings for teaching dyeing principles and techniques. In summary, the Oscillation Type Water Bath Dyeing Machine is an essential tool in textile laboratories, offering precise control over dyeing parameters, improving efficiency, and ensuring high-quality, reproducible results across various textile materials. Features of Oscillation Type Water Bath Dyeing Machine:- Oscillating Mechanism - Provides back-and-forth movement of beakers for uniform dye penetration and sample agitation.

- Multiple Beaker Capacity - Supports dyeing of 12–24 samples simultaneously, ideal for comparative lab testing.

- Digital Temperature Control - Maintains precise water bath temperature (typically up to 99°C), essential for consistent dyeing.

- Variable Oscillation Speed - Adjustable speed settings (e.g., 50–200 cycles/min) to suit different materials and processes.

- Programmable Settings - Allows setting of temperature, time, and speed for repeatable and automated dyeing cycles.

- Stainless Steel Construction - Corrosion-resistant frame and bath for durability in chemical environments.

- Beaker Safety Holders - Secure placement of beakers to prevent spills and maintain consistent treatment.

- Compact Design - Lab-friendly size for easy integration into research and quality control spaces.

- Low Liquor Ratio Operation - Efficient dyeing using minimal dye bath volume (e.g., 1:5 to 1:20), reducing chemical and water use.

- Quiet and Stable Performance

water bath/Shaker bath Dyeing machine

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

IR Dyeing Machine Dunlin

IR Dyeing Machine Dunlin

IR Dyeing machine Dunlin is Safe, high efficiency, environment friendly, energy saving, optimum for new dyeing small sample machines0 - 3.5 ℃ / min Cooling rate 0.2 - 5 ℃ / min Cooling method Air-cooled Rotation speed 0 - 60 rpm Liquor ratio 1:5 -1:100 Power supply 1∮AC 220V 50/60HZ Dimensions( L x W x H) 670×670×780mm 860×680×780mm Weight 100kg 120kg Standard Accessories Cups 1set

Put the test sample. Cups stand 1set Place where to put cups. Protective glove 1set To avoid to be hurt by HT cups. Model: IF-24SCapacity: 24 pots Brad: DUNLIN Origin: China

Color dyeing tests for various dyestuffs of IR Dyeing machine Dunlin- Step dyeing tests. C. Dispersing, levelling and impregnating test. D. High or low liquor ratio exhausting tests. E. Fabric steak and staining tests. F. Concentration tests and others. Protection and Safety gates to protect. Temperature control accuracy +/- 0.2degree

IR Dyeing machine

Fabric air permeability tester

Fabric Air Permeability Tester

Fabric Air Permeability Tester is a lab instrument used to measure how easily air passes through a fabric. It quantifies the air permeability, which is crucial for evaluating breathability, comfort, and functional performance in textiles. Purpose Fabric Air Permeability Tester: It determines the rate of airflow through a fabric sample under a set air pressure, typically reported in units like cm³/cm²/s or L/m²/s. Working Principle: The tester creates a pressure difference across the fabric sample and measures the volume of air flowing through it. Higher air permeability means the fabric is more breathable. Main Components of Fabric Air Permeability Tester: - Test Head / Clamp: Holds the fabric securely without leakage. - Pressure Regulator: Maintains a constant air pressure during testing. - Flow Meter or Digital Sensor: Measures the actual airflow rate through the fabric. - Display Unit: Shows readings of air permeability instantly. Applications of Fabric Air Permeability Tester: - Performance textiles (sportswear, PPE) - Technical fabrics (filters, tents, airbags) - Medical textiles (masks, gowns) - Nonwovens and industrial materials Benefits of Fabric Air Permeability Tester:- Accurate Breathability Measurement - Precisely measures how breathable a fabric is, essential for comfort and performance.

- Supports Quality Control - Ensures consistent air permeability in fabric batches, critical for products like PPE, sportswear, and filters.

- Enhances Product Design - Helps in selecting or engineering fabrics with the right airflow properties for specific uses.

- Standard Compliance - Conforms to international testing standards (e.g., ASTM D737, ISO 9237), ensuring global credibility.

- Quick and Reliable Testing - Provides rapid results, increasing lab efficiency and production decision-making speed.

- Wide Material Compatibility - Suitable for woven, nonwoven, knitted fabrics, and even paper or coated materials.

- Improves Functional Performance - Helps optimize products for ventilation, moisture control, and thermal comfort.

- Reduces Product Failure - Identifies underperforming fabrics early, minimizing risks in high-performance applications.

- Digital Display - Shows air permeability readings clearly in units like L/m²/s or cm³/cm²/s.

- Precise Test Head/Clamp - Provides an airtight seal to prevent air leakage and ensure accurate results.

- Adjustable Pressure Settings - Allows testing under various pressure drops (e.g., 10–2500 Pa), depending on fabric type.

- Automatic Airflow Measurement - Built-in sensors or flow meters capture airflow rate automatically for quick analysis.

- Multiple Test Area Sizes - Interchangeable test plates to match different sample sizes and standard requirements.

- Data Logging and Export - Some models include USB or software connectivity for storing and exporting test results.

- Standard Compliance - Conforms to ASTM D737, ISO 9237, BS 5636, DIN 53887, etc.

- Robust Construction - Built with corrosion-resistant materials and durable components for long-term lab use.

- Low Maintenance - Simple cleaning and calibration process for reliable performance.

- Compact and User-Friendly Design - Ideal for lab benches and easy operation with minimal training.

- Prepare the Sample - Cut the fabric sample to the required size (usually circular, e.g., 20 cm²).

- Mount the Sample - Place the fabric securely in the test clamp or holder, ensuring no wrinkles or gaps.

- Set Test Parameters - Adjust the air pressure drop according to the fabric type or standard (e.g., 100 Pa).

- Start the Test - Turn on the air supply and start the airflow through the fabric.

- Read the Measurement - The digital display will show the air permeability value in the selected units.

- Record the Results - Note the readings or export data if the device supports it.

- Repeat if needed - Test multiple samples or areas for accuracy and average the results.

- Clean and Maintain - After testing, clean the clamp and ensure the device is calibrated regularly.

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm ICI Pilling & Snagging Test Machine

Steam Soaping machine

Steam Soaping Machine

A Steam Soaping Machine is a specialized laboratory apparatus used in textile dyeing processes, particularly for post-dyeing treatments like soaping, which enhances color fastness and removes unfixed dyes from fabric samples. This machine is designed to perform soaping treatments on dyed textile samples using steam. Soaping is a critical step in dyeing, especially for reactive dyes, as it removes unfixed dye particles, ensuring better color fastness and preventing dye bleeding. The steam soaping process involves treating the dyed fabric with a soaping solution at elevated temperatures, facilitated by steam, to achieve optimal results. ⚙️ Key Features of Steam Soaping Machine - Beaker Material: Constructed with high-grade 316L stainless steel for excellent corrosion resistance and durability.- Operation Modes: Offers both automatic control and manual water filling options, providing flexibility in operation. - Drainage System: Equipped with an automatic drainage device for efficient removal of used solutions.- Temperature Control: Precise temperature regulation to maintain optimal soaping conditions.- Compact Design: Suitable for laboratory settings, occupying minimal space while delivering effective performance. ✅ Benefits of Steam Soaping Machine - Enhanced Color Fastness: Effectively removes unfixed dyes, resulting in improved wash and rub fastness of the fabric.- Efficient Processing: Reduces the time required for post-dyeing treatments compared to conventional methods.- Consistent Results: Provides uniform treatment across samples, ensuring reproducibility in testing and quality control.- Resource Optimization: Minimizes water and chemical usage through controlled processing parameters.- Versatility: Applicable to various fabric types and dye classes, making it a valuable tool in research and development. Typical Applications - Laboratory Testing: Used in dyeing laboratories for evaluating the fastness properties of dyed samples. - Research and Development: Assists in developing and optimizing dyeing processes and formulations. - Quality Control: Ensures that dyed fabrics meet specified fastness standards before bulk production. In summary, a Steam Soaping Machine is an essential laboratory instrument in the textile industry, facilitating efficient and effective post-dyeing treatments to enhance the quality and durability of dyed fabrics. Features of Steam Soaping Machine:- High-Grade Stainless Steel Beakers - Made from 316L stainless steel for excellent chemical and heat resistance.

- Steam-Based Heating - Uses direct or indirect steam to maintain consistent high temperatures ideal for soaping.

- Precise Temperature Control - Maintains stable temperatures (typically up to 98–100°C) for effective removal of unfixed dyes.

- Automatic and Manual Modes - Offers both programmable automatic cycles and manual operation for flexibility.

- Beaker Agitation or Rotation - Ensures uniform soaping action across fabric surfaces.

- Automatic Drainage System - Efficiently removes used soaping solution to speed up cycle changeovers.

- Compact Design - Fits well in lab settings while allowing multiple samples to be processed simultaneously.

- Safety Features - Includes pressure and temperature protection systems to ensure safe operation.

- Low Water and Chemical Use - Designed for minimal liquor ratios, enhancing sustainability.

- User-Friendly Interface - Simple digital controls or touch panel for easy operation and cycle programming.

- Prepare the Dyed Sample - After dyeing, rinse the fabric to remove surface dye and prepare it for soaping.

- Load the Fabric - Place the dyed fabric or sample into the beakers or holders inside the machine.

- Add Soaping Solution - Pour the prepared soaping agent (usually a detergent solution) into the beakers or tank as per recipe.

- Set Parameters

- Start the Cycle - Begin the soaping process. The machine will heat the solution using steam and agitate/rotate the beakers for even treatment.

- Drain and Rinse - After the cycle ends, the machine may auto-drain. Rinse the fabric with warm water to remove residual chemicals.

- Unload the Samples - Carefully remove the fabric. Inspect for evenness and color fastness improvement.

- Clean the Machine - Rinse and dry the beakers or tank to maintain hygiene for the next use.

used for sample soaping after dyeing in laboratory

Beaker material: 316L S/S

automatic control / manual filling water device, with automatic drainage device.

Steam Soaping machine Dunlin price in Bangladesh

Steam Soaping machine Dunlin in textile testing equipment

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Steam Soaping machine Dunlin price in Bangladesh

used for sample soaping after dyeing in laboratory

Beaker material: 316L S/S

automatic control / manual filling water device, with automatic drainage device.

Steam Soaping machine Dunlin price in Bangladesh

Steam Soaping machine Dunlin in textile testing equipment

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Steam Soaping machine Dunlin price in Bangladesh

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated