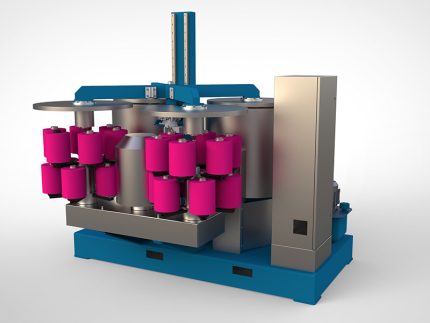

Steam Soaping machine

$0.00

Steam Soaping Machine

A Steam Soaping Machine is a specialized laboratory apparatus used in textile dyeing processes, particularly for post-dyeing treatments like soaping, which enhances color fastness and removes unfixed dyes from fabric samples.

This machine is designed to perform soaping treatments on dyed textile samples using steam. Soaping is a critical step in dyeing, especially for reactive dyes, as it removes unfixed dye particles, ensuring better color fastness and preventing dye bleeding. The steam soaping process involves treating the dyed fabric with a soaping solution at elevated temperatures, facilitated by steam, to achieve optimal results.

⚙️ Key Features of Steam Soaping Machine

– Beaker Material: Constructed with high-grade 316L stainless steel for excellent corrosion resistance and durability.- Operation Modes: Offers both automatic control and manual water filling options, providing flexibility in operation.

– Drainage System: Equipped with an automatic drainage device for efficient removal of used solutions.- Temperature Control: Precise temperature regulation to maintain optimal soaping conditions.- Compact Design: Suitable for laboratory settings, occupying minimal space while delivering effective performance.

✅ Benefits of Steam Soaping Machine

– Enhanced Color Fastness: Effectively removes unfixed dyes, resulting in improved wash and rub fastness of the fabric.- Efficient Processing: Reduces the time required for post-dyeing treatments compared to conventional methods.- Consistent Results: Provides uniform treatment across samples, ensuring reproducibility in testing and quality control.- Resource Optimization: Minimizes water and chemical usage through controlled processing parameters.- Versatility: Applicable to various fabric types and dye classes, making it a valuable tool in research and development.

Typical Applications

– Laboratory Testing: Used in dyeing laboratories for evaluating the fastness properties of dyed samples.

– Research and Development: Assists in developing and optimizing dyeing processes and formulations.

– Quality Control: Ensures that dyed fabrics meet specified fastness standards before bulk production.

In summary, a Steam Soaping Machine is an essential laboratory instrument in the textile industry, facilitating efficient and effective post-dyeing treatments to enhance the quality and durability of dyed fabrics.

Features of Steam Soaping Machine:

- High-Grade Stainless Steel Beakers – Made from 316L stainless steel for excellent chemical and heat resistance.

- Steam-Based Heating – Uses direct or indirect steam to maintain consistent high temperatures ideal for soaping.

- Precise Temperature Control – Maintains stable temperatures (typically up to 98–100°C) for effective removal of unfixed dyes.

- Automatic and Manual Modes – Offers both programmable automatic cycles and manual operation for flexibility.

- Beaker Agitation or Rotation – Ensures uniform soaping action across fabric surfaces.

- Automatic Drainage System – Efficiently removes used soaping solution to speed up cycle changeovers.

- Compact Design – Fits well in lab settings while allowing multiple samples to be processed simultaneously.

- Safety Features – Includes pressure and temperature protection systems to ensure safe operation.

- Low Water and Chemical Use – Designed for minimal liquor ratios, enhancing sustainability.

- User-Friendly Interface – Simple digital controls or touch panel for easy operation and cycle programming.

How to Use a Steam Soaping Machine:

- Prepare the Dyed Sample – After dyeing, rinse the fabric to remove surface dye and prepare it for soaping.

- Load the Fabric – Place the dyed fabric or sample into the beakers or holders inside the machine.

- Add Soaping Solution – Pour the prepared soaping agent (usually a detergent solution) into the beakers or tank as per recipe.

- Set Parameters

– Use the control panel to set:

– Temperature (usually 95–98°C)

– Soaping time (typically 10–20 minutes)

– Steam mode (direct or indirect, if applicable)

- Start the Cycle – Begin the soaping process. The machine will heat the solution using steam and agitate/rotate the beakers for even treatment.

- Drain and Rinse – After the cycle ends, the machine may auto-drain. Rinse the fabric with warm water to remove residual chemicals.

- Unload the Samples – Carefully remove the fabric. Inspect for evenness and color fastness improvement.

- Clean the Machine – Rinse and dry the beakers or tank to maintain hygiene for the next use.

Safety Tips:

– Wear gloves and goggles.

– Do not open the lid during operation.

– Ensure steam connections are secure.

Steam Soaping machine

used for sample soaping after dyeing in laboratory

Beaker material: 316L S/S

automatic control / manual filling water device, with automatic drainage device.

Steam Soaping machine Dunlin price in Bangladesh

Steam Soaping machine Dunlin in textile testing equipment

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Steam Soaping machine Dunlin price in Bangladesh

Related products

Bursting strength tester

Bursting strength tester

true burst

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

- Bursting pressure can reach up to 1.2MPa 5. The maximum burst and expansion degree can reach 70mm. 6. Strengthen the lighting system on the test surface. 7. The main aerodynamic force helps to clamp the sample system. 8. A variety of test areas are available, and the switching is easy.

- A variety of unit conversions between Chinese and English. 10. Reliable anti-pinch safety protection design. [Technical parameter]: 1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized) 2. The minimum graduation value: 0.0001Mpa 3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree pressurization.

Laboratory tenter

Laboratory Tenter

A Laboratory Tenter (or Lab Stenter) is a small-scale version of an industrial tenter machine used in textile finishing. It is designed for heat-setting, drying, and finishing of fabric samples under controlled conditions in textile testing labs or R&D departments. Key Features:- Heat-Setting and Drying - Simulates the process of setting fabric dimensions and applying finishes using controlled temperature and tension.

- Fabric Width Control - Uses clips or pins on chains or rails to hold fabric edges and stretch them to desired width, just like in full-size tenters.

- Adjustable Temperature and Speed - Digital controls allow precise setting of drying/curing temperature and conveyor speed to match production conditions.

- Compact Design - Bench-top or floor-standing units suitable for labs with limited space.

- Transparent Viewing Chamber - Allows visual inspection of fabric behavior during processing.

- Versatile Application Range - Can process woven, knitted, and nonwoven fabrics of various compositions (cotton, polyester, blends, etc.).

- Accurate Simulation of Production - Replicates industrial finishing processes for reliable lab-scale testing and development.

- Improves Fabric Quality- Allows precise control of heat and tension, optimizing fabric properties like shrinkage, dimensional stability, and hand feel.

- Cost-Effective - Enables process trials and fabric development without using full-scale production equipment.

- Speeds Up R&D - Facilitates quick testing and adjustment of settings for new fabric styles or finishes.

- Versatile Applications - Suitable for drying, heat-setting, finishing, and evaluating different types of fabrics and treatments.

- Space-Efficient - Compact design fits easily into textile labs or sample rooms.

- Energy Efficient- Uses less power than industrial machines, ideal for small-scale and repeated testing.

- Process Control and Reproducibility- Digital controls ensure consistent and repeatable results, aiding in quality assurance and product development.

- Enhances Safety - Built with lab use in mind, featuring insulation and safety systems to protect users.

- Precise Temperature Control - Digital temperature setting (typically up to 220–250°C) for accurate heat-setting and drying.

- Adjustable Fabric Width - Equipped with clip or pin chains to hold and stretch fabric across the width, simulating real stentering.

- Variable Conveyor or Chain Speed- Adjustable speed to control fabric dwell time during processing.

- Compact and Lab-Friendly Design - Designed for bench-top or small floor space use in textile labs.

- Transparent Chamber Window - Allows monitoring of fabric behavior during treatment.

- Digital Display and Control Panel - Easy operation for setting temperature, speed, and time.

- Uniform Heat Distribution- Ensures even treatment across the fabric width for accurate testing.

- Stainless Steel Construction - Durable, corrosion-resistant body for long-term use at high temperatures.

- Safety Features - Includes over-temperature protection, insulated body, and emergency stop functions.

- Sample Versatility - Suitable for various fabric types (woven, knit, synthetic, blends) and lab finishing tasks.

laboratory mini tenter

Digital hot plate-magnetic stirrer

Digital hot plate-magnetic stirrer

Digital hot plate-magnetic stirrer

- Magnetic Stirrer:

- Digital Display and Controls:

- Temperature Sensors: - Built-in or external probes (like a PT100 or thermocouple) for accurate temperature control.

- Precision and Control- Digital Interface: Allows accurate setting and monitoring of temperature and stirring speed.- Consistent Results: Ensures reproducibility in experiments and solution preparations.

- Efficient Mixing and Heating- Uniform Mixing: Magnetic stirring eliminates hotspots and ensures even distribution of solutes.- Simultaneous Operation: Ability to heat and stir at the same time improves efficiency.

- Safety Features- Overheat Protection: Prevents accidents by automatically shutting off at unsafe temperatures.- Sealed Surface: Reduces risk of contamination and easy to clean.

- Versatility

- Compact and User-Friendly- Takes up minimal bench space.- Simple to operate with user-friendly controls and displays.

- Durability- High-quality materials like ceramic or stainless steel tops resist corrosion and wear.

- Time-Saving Speeds up preparation of solutions and reactions compared to manual stirring and separate heating. Would you like these benefits presented in a slide format or for a product brochure?

Digital Elmendorf tearing tester

Digital Elmendorf Tearing Tester

Digital Elmendorf Tearing Tester is a precision instrument used to measure the tear strength of materials like woven fabrics, paper, plastic films, and nonwovens. It determines how much force is required to continue tearing a pre-slit sample. Key Functions of Digital Elmendorf Tearing Tester: - Measures propagation tear resistance, not initial tear. - Uses a pendulum to apply force; the energy lost during tearing is calculated to determine tear strength. - Equipped with a digital display for direct reading of results in grams or millinewtons. Core Components: - Pendulum Arm: Applies tearing force. - Clamps: Secure the sample before and after the tear. - Cutting Blade: Creates a precise slit at the start of the test. - Digital Display Unit: Shows the tearing force result clearly and instantly. - Counterweights: Optional weights for increasing test range (for stronger materials). Applications of Digital Elmendorf Tearing Tester: - Testing tear resistance of: - Textile fabrics (especially woven) - Paper and cardboard - Plastic films - Nonwovens - Packaging materials Benefits of Digital Elmendorf Tearing Tester:- Accurate Tear Strength Measurement - Provides precise data on tear resistance, critical for quality control and product performance.

- Digital Readout - Easy-to-read display gives instant, reliable results without manual calculations.

- High Reproducibility - Ensures consistent test outcomes due to controlled tearing angle and speed.

- Fast Testing Process - Simple loading and quick test cycle increase lab efficiency.

- Suitable for Various Materials - Tests a wide range of flexible materials like textiles, paper, plastic, and packaging.

- Customizable Range - Use of optional weights extends the test range for low to high tear strength materials.

- Low Sample Waste - Requires small fabric or material samples, reducing waste during testing.

- Standards Compliance - Meets international testing standards (e.g., ASTM D1424, ISO 13937) for credibility and uniformity.

- Precision Sample Clamp - Securely holds samples in place to ensure accurate tear initiation.

- Pre-Cutting Blade - Integrated knife creates a precise initial slit in the sample before tearing.

- User-Friendly Interface - Simple buttons and screen navigation for ease of operation.

- Standard Test Compliance - Compatible with ASTM D1424, ISO 1974, ISO 13937, and other tear strength standards.

- Sturdy Construction - Made with durable materials for long-lasting performance and stable operation.

- Compact Design - Space-efficient footprint ideal for laboratory environments.

- Data Output Options- Some models offer USB or printer connectivity for result documentation.

- Prepare the Sample - Cut the material (fabric, paper, film, etc.) to standard size (typically 100 × 63 mm for textiles) and slit it with the pre-cutter as required.

- Select Pendulum Weight - Choose the appropriate pendulum or add counterweights based on expected tear strength.

- Calibrate the Machine - Set the pendulum to its starting position and zero the display.

- Clamp the Sample - Fix one half of the sample in the stationary clamp and the other in the moving clamp.

- Cut the Initial Slit - Use the integrated blade to make a precise cut at the marked slit area (usually 20 mm).

- Release the Pendulum - Trigger the pendulum to swing and tear the sample through the pre-slit.

- Read the Result - The digital display will show the tearing force automatically (in g, mN, or cN).

- Record or Export Data - Save or print the result if your model supports USB or printer connection.

- Reset for Next Test - Reposition the pendulum and prepare a new sample for the next cycle.

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.)

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.) Controller For IR Dyeing Machine

Controller For IR Dyeing Machine

IR Dyeing machine controller

- Temperature Control:- Precisely regulates the infrared heaters to maintain uniform temperature across the dye bath. - Supports customizable heating curves (ramp-up, hold, and cool-down phases).

- Programmable Logic Control (PLC): - Allows operators to set and automate dyeing programs for different fabrics and dye types. - Supports multiple recipes or programs for different batches.

- Real-Time Monitoring and Feedback: - Monitors parameters like temperature, fabric rotation, bath circulation, and timing. - Provides real-time data and alarms for deviations.

- Touchscreen Interface / HMI (Human Machine Interface): - User-friendly interface for configuring and monitoring processes. - Multi-language support and graphical display of process curves.

- Data Logging and Traceability: - Records process data for quality control and traceability.

- Energy Efficiency Optimization: - Manages IR heater output to reduce energy usage. - Often includes features for auto shut-off or idle mode.

- Safety Features: - Includes emergency stop, over-temperature protection, and fault detection systems. 8. Connectivity: - Modern controllers may support Ethernet, Modbus, or other industrial communication protocols for integration into factory automation systems.

- Improved Dyeing Accuracy and Consistency

- Enhanced Energy Efficiency- Infrared heating is more energy-efficient than traditional heating methods.- The controller optimizes energy use by adjusting the IR output based on process needs, reducing overall energy consumption.

- Time Savings- Faster heating and cooling cycles due to infrared technology.- Automated processes reduce manual intervention and cycle times. 4. Better Process Control- Programmable dyeing cycles and precise control over each stage (heating, dyeing, rinsing, cooling).- Real-time monitoring and adjustments improve reliability.

- Reduced Water and Chemical Usage- More efficient dye penetration and fixation mean less water and fewer chemicals are needed for reprocessing or corrections.6. Lower Operational Costs

- Enhanced Safety Built-in alarms, emergency shut-off and automatic fault detection enhance operational safety.8. Data Logging and Traceability- Ability to record and review dyeing process data helps in quality control and troubleshooting.- Facilitates compliance with industry standards and audits.

- User-Friendly Operation- Modern touchscreen interfaces make it easier for operators to manage and monitor processes.- Multilingual support and visual feedback enhance usability.

Stretch Recovery Tester Static Method

Stretch Recovery Tester Static Method

Stretch Recovery Tester

- A sample is stretched to a predetermined extension or force.

- The stretch is maintained for a set period.

- After removing the load, the recovery (return to original length) is measured after a fixed time.

- The fabric sample is clamped and stretched to a specific length or force.

- It’s held for a fixed duration (e.g., 1–5 minutes).

- The tension is released, and the sample is allowed to recover.

- The recovered length is measured after a set time.

Stretch Recovery Tester

Automatic Bobbin Hydro extractor

Automatic Bobbin Hydro extractor

Automatic Bobbin Hydro extractor

- Computer system: Foshan HuaGao Chinese English computer, equipped with LG PLC.

- Electromagnetic valve: Ningbo Jiaerling

- Frequency converter: Use Made in China frequency converters.

- Pump: self-made high head and large flow centrifugal water pump.

- Main pump motor: Anhui Wannan Motor.

- Master cylinder liquid level: Use 4-20mA analog signal output.

- Level of deputy temporary worker: use foam water level gauge. (American Mike)

- Temperature detection and display: digital temperature display instrument, dual temperature measuring probes.

- The safety system has a triple cylinder head safety interlock mechanism, and the main cylinder is equipped with a stainless

- steel safety valve.

- Heat exchanger: external spacer heating.

- Feeding system: Quantitative feeding based on the process curve.

- Circulation system: The main pump flows internally and externally, which is automatically controlled by a computer or manually controlled by a relay.

- Valves: Y valves are used for heating, stainless steel Y valves are used for single inlet and single row, and other Y valves are produced by joint ventures.

- Temperature control: on-off temperature control, controlled by a computer, with automatic heating, cooling, and insulation functions.

- Dyeing method: air cushion type.

- Opening method: manual opening.

- Surface treatment: polishing inside and outside the cylinder.

- Cage: Each dyeing machine is equipped with butterfly blades and self-locking locks.

- Body plate: high-quality stainless steel. (S31603)

- Bath ratio: 1:5-1:6

- Chemical material system: including heating and water adding functions, including overflow type salt melting device.

- Overflow cleaning: The cleaning port is installed on the upper part of the cylinder port, and the bottom of the cylinder is filled with water, while the cylinder is drained for easy cleaning.

- Commutation method: Novel "U" type commutation.

- Random accessories: Each model comes with one set of mechanical seals, pot mouth rings, and reversing seals for the main and auxiliary pumps.

Automatic Bobbin Hydro extractor

Card winding machine

Card Winding Machine

Card Winding Machine

Card Winding Machine

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated