Laboratory mini stenter Dryer

Laboratory mini stenter Dryer

A Laboratory Mini Stenter Dryer is a compact, lab-scale machine designed to simulate the drying and heat-setting processes used in textile finishing. It mimics the function of industrial stenter machines but on a much smaller scale, making it ideal for testing fabric behavior, shrinkage, and finish quality under controlled conditions. Key Features:- Controlled Heating System

- Adjustable Fabric Width

- Variable Speed Conveyor - Allows control over fabric dwell time for drying or heat-setting.

- Compact and Bench-Top Design - Space-saving design ideal for textile labs and R&D units.

- Digital Controls - Easy-to-use digital interface for setting temperature, conveyor speed, and process time.

- Transparent Viewing Window - Allows operators to monitor fabric movement and drying visually.

- Low Energy Consumption - Designed for lab use, consuming less power than industrial models.

- Accurate Simulation of Production - Mimics industrial stenter conditions on a lab scale, ideal for pre-production testing and R&D.

- Cost-Effective Testing - Enables testing and fabric finishing without the high cost or space requirements of full-scale machines.

- Energy Efficient - Consumes less power compared to large stenters, making it economical for small-scale or frequent use.

- Precise Control - Offers accurate control of temperature, speed, and fabric tension, ensuring consistent results.

- Space-Saving Design - Compact and bench-top friendly, perfect for laboratories with limited space.

- Multiple Applications - Useful for drying, heat-setting, shrinkage testing, and evaluating chemical finishes.

- Faster Development Cycles - Speeds up new product development by allowing rapid sample testing and adjustments.

- Improved Fabric Quality - Helps optimize finishing parameters for better dimensional stability, hand feel, and appearance.

- Safe and User-Friendly- Designed with lab safety in mind, including temperature safety controls and easy operation.

- Compact Bench-Top Design - Ideal for laboratory use with limited space requirements.

- Adjustable Temperature Control - Precise heating (usually up to 220–250°C) with digital controllers for accurate processing.

- Variable Conveyor Speed- Allows adjustment of fabric dwell time for different drying or heat-setting needs.

- Width Adjustment Mechanism - Equipped with clips or pins to stretch and fix fabric width-wise, simulating industrial stenter conditions.

- Transparent Viewing Window - Enables visual monitoring of fabric movement and drying inside the chamber.

- Digital Display Panel- Easy-to-use interface for setting and monitoring temperature, speed, and time.

- Stainless Steel Construction- Durable and corrosion-resistant for long-term use at high temperatures.

- Uniform Heat Distribution- Ensures consistent fabric treatment across the width.

- Safety Features- Over-temperature protection and insulated body for operator safety.

- Versatile Applications - Suitable for drying, heat-setting, shrinkage testing, and chemical finish evaluations.

Laboratory Padder

Laboratory Padder

A Laboratory Padder is a compact, laboratory-scale machine used to apply liquids like dyes, chemicals, and finishes to fabric samples. It simulates the padding process in textile manufacturing, where fabric is passed through a liquid solution, then squeezed between rollers to ensure uniform application and absorption. Key Features of a Laboratory Padder:- Adjustable Rollers - The fabric is passed through two or more rollers to apply even pressure and squeeze out excess solution, ensuring uniform chemical or dye application.

- Variable Pressure Control - Allows adjustment of roller pressure for different fabric types and chemical formulations, ensuring optimal penetration without damage.

- Solution Bath - Holds the liquid (e.g., dye, finish, or other chemical treatments) in a bath through which the fabric is dipped before passing through the rollers.

- Fabric Speed Control - Adjustable conveyor speed allows for control over the time the fabric spends in contact with the liquid solution, affecting the degree of treatment.

- Digital Control Panel - Provides easy adjustment of pressure, speed, and solution volume to ensure precise and reproducible results.

- Compact Design - Smaller, lab-scale version of industrial padders, ideal for research, development, and small-scale testing.

- Safety Features - Safety guards, emergency stops, and proper handling mechanisms to prevent accidents during operation.

- Precise Application of Chemicals - Provides uniform and controlled application of dyes, finishes, and other chemicals, ensuring consistent results.

- Small-Scale Testing - Ideal for small sample testing, allowing for fabric treatment without needing full-scale production equipment.

- Versatile Use - Suitable for dyeing, finishing, and applying various chemical treatments, making it a flexible tool for R&D labs.

- Cost-Effective - Reduces the need for large-scale machinery and the associated costs, while providing reliable results for small batches.

- Controlled Fabric Treatment - Offers adjustable pressure, speed, and solution concentration, enabling fine-tuned processing for different fabric types and applications.

- Accelerates Development - Speeds up the testing and development of new products or finishes, improving time-to-market for textile manufacturers.

- Energy Efficient - Consumes less energy compared to larger, industrial-scale machines, making it suitable for lab use.

- Compact and Space-Saving - Designed for laboratory environments with limited space, without compromising on functionality.

- Reproducible Results - Ensures consistent application of treatments across multiple samples, aiding in accurate testing and comparison.

- Adjustable Roller Pressure - Allows precise control over the pressure applied to the fabric, ensuring uniform chemical or dye application.

- Variable Speed Control - Adjustable conveyor speed for controlling the time the fabric spends in the solution bath, influencing the absorption rate.

- Solution Bath - Holds dye, chemicals, or finishes, and the fabric passes through this bath before moving to the rollers.

- Digital Control Panel - Easy-to-use interface for setting and adjusting parameters like speed, pressure, and solution concentration.

- Compact and Lab-Friendly Design - Designed for smaller, space-efficient use in textile labs, allowing for small sample testing.

- Roller Gap Adjustment - Allows for fine-tuning of the gap between rollers to regulate the amount of solution squeezed out of the fabric.

- Stainless Steel Construction - Durable and resistant to corrosion from the chemicals used in textile treatments.

- Safety Mechanisms - Includes safety guards, emergency stops, and user protection features during operation.

- Even and Controlled Application - Ensures even distribution of treatments (dye, finish, etc.) on fabric with minimal waste.

- Versatility in Application - Can be used for a wide range of textiles and treatments, including dyeing, softening, flame-retardant treatments, etc.

- Prepare the Fabric Sample - Cut the fabric sample to the required size for the experiment. Ensure it’s clean and free of any debris.

- Prepare the Solution - Mix the dye, chemical, or finish solution according to the desired concentration and the fabric's needs. Ensure that the solution is homogeneous.

- Set the Parameters - Pressure: Adjust the roller pressure based on the fabric type. Different fabrics require different pressure levels to ensure uniform application. - Speed: Set the fabric conveyor speed depending on the desired treatment time (longer exposure for deeper treatment).

- Load the Fabric into the Machine - Place the fabric carefully into the machine. The fabric should go through the solution bath and then pass between the rollers.

- Start the Machine - Turn on the machine and allow the fabric to pass through the rollers. The solution will be evenly applied to the fabric as it moves through the bath and is squeezed by the rollers.

- Monitor the Process - Keep an eye on the fabric to ensure it is being treated uniformly and there are no blockages or fabric jams.

- Unload the Fabric - Once the fabric has been treated, carefully remove it from the machine. Inspect for even application of the solution and any excess liquid.

- Dry or Process Further - Depending on the treatment, proceed with further steps such as drying, heat setting, or curing, as required by the experiment or process.

Mini Lab Dyeing Padder

Laboratory tenter

Laboratory Tenter

A Laboratory Tenter (or Lab Stenter) is a small-scale version of an industrial tenter machine used in textile finishing. It is designed for heat-setting, drying, and finishing of fabric samples under controlled conditions in textile testing labs or R&D departments. Key Features:- Heat-Setting and Drying - Simulates the process of setting fabric dimensions and applying finishes using controlled temperature and tension.

- Fabric Width Control - Uses clips or pins on chains or rails to hold fabric edges and stretch them to desired width, just like in full-size tenters.

- Adjustable Temperature and Speed - Digital controls allow precise setting of drying/curing temperature and conveyor speed to match production conditions.

- Compact Design - Bench-top or floor-standing units suitable for labs with limited space.

- Transparent Viewing Chamber - Allows visual inspection of fabric behavior during processing.

- Versatile Application Range - Can process woven, knitted, and nonwoven fabrics of various compositions (cotton, polyester, blends, etc.).

- Accurate Simulation of Production - Replicates industrial finishing processes for reliable lab-scale testing and development.

- Improves Fabric Quality- Allows precise control of heat and tension, optimizing fabric properties like shrinkage, dimensional stability, and hand feel.

- Cost-Effective - Enables process trials and fabric development without using full-scale production equipment.

- Speeds Up R&D - Facilitates quick testing and adjustment of settings for new fabric styles or finishes.

- Versatile Applications - Suitable for drying, heat-setting, finishing, and evaluating different types of fabrics and treatments.

- Space-Efficient - Compact design fits easily into textile labs or sample rooms.

- Energy Efficient- Uses less power than industrial machines, ideal for small-scale and repeated testing.

- Process Control and Reproducibility- Digital controls ensure consistent and repeatable results, aiding in quality assurance and product development.

- Enhances Safety - Built with lab use in mind, featuring insulation and safety systems to protect users.

- Precise Temperature Control - Digital temperature setting (typically up to 220–250°C) for accurate heat-setting and drying.

- Adjustable Fabric Width - Equipped with clip or pin chains to hold and stretch fabric across the width, simulating real stentering.

- Variable Conveyor or Chain Speed- Adjustable speed to control fabric dwell time during processing.

- Compact and Lab-Friendly Design - Designed for bench-top or small floor space use in textile labs.

- Transparent Chamber Window - Allows monitoring of fabric behavior during treatment.

- Digital Display and Control Panel - Easy operation for setting temperature, speed, and time.

- Uniform Heat Distribution- Ensures even treatment across the fabric width for accurate testing.

- Stainless Steel Construction - Durable, corrosion-resistant body for long-term use at high temperatures.

- Safety Features - Includes over-temperature protection, insulated body, and emergency stop functions.

- Sample Versatility - Suitable for various fabric types (woven, knit, synthetic, blends) and lab finishing tasks.

laboratory mini tenter

Martindale abrasion tester Updated

Martindale abrasion tester updated

Latest Update 1 A+

- Clothing sample weight hammer:397±2g Furniture decoration sample weight hammer:597±2g C. Stainless steel discs:260±1g

- Effective friction diameter of grinding block: Type A 198g(3kpa) friction head 28.8-0.084mm Type B 155g(1.52N) friction head 90-0.10mm 6. Relative velocity of gripper and grinding table:50 + 2R / MI (20-70r / min adjustable) 7. Sampling hammer quality:2385±10g 8. Shape size:870×580×300mm 9. power supply:AC220V 50Hz 500W 10.Weight:73KG.

- [Standard accessories] Items and specifications Qty Notes Main machine 1Power cable 1A type 198g Friction head 9 B type 155g(1.52N) Friction head 9 597g Hammer 9 397g Hammer 9, 666666666 260g Stainless steel disc 9, 2385g Holding hammer 1,B Friction head felt 18 ¢90mm Steel ball 6, Rubber ring 18, Inner Hexagonal Wrench 1

- Sampler 1, Fuse 2 3A, Standard felt 18, Weight:750±50g/m2, Thickness:2.5±0.5mm, Standard foam lining 40, Density:0.03g/cm3,Thickness:3mm,Standard abrasive 9 Circular shear template Each φ140mm、φ38mm,Small screw knife 1, Bottom foot 4

Orbital Shaker Machine

Orbital Shaker Machine

Orbital Shaker Machine

- Orbital Motion - Provides a smooth circular shaking pattern, ideal for gentle mixing without foaming or splashing.

- Adjustable Speed Control - Speed typically ranges from 50 to 300 RPM, depending on the model and application.

- Timer Function - Allows users to set shaking time from minutes to hours for precise control of experiments.

- Platform with Clamps or Mats - Holds flasks, beakers, test tubes, or trays securely during operation.

- Digital Display (in advanced models) - Shows speed and time settings for accurate and repeatable performance.

- Variable Capacity - Available in sizes to accommodate different lab needs—from a few samples to dozens.

- Quiet Operation - Designed for minimal vibration and noise during continuous use.

- Uniform Mixing - Ensures even distribution of dyes, chemicals, or cultures without manual stirring.

- Gentle Agitation - Ideal for delicate samples like cell cultures or fabric swatches, reducing damage or splashing.

- Hands-Free Operation - Allows continuous, unattended mixing—improving lab efficiency and freeing up personnel.

- Customizable Settings - Adjustable speed and timer let users tailor mixing to specific sample types and needs.

- Versatile Use - Suitable for a wide range of applications including dye mixing, sample incubation, chemical reaction enhancement, and microbial growth.

- Enhanced Reproducibility - Consistent shaking patterns and digital controls ensure repeatable results across experiments.

- Reduces Human Error - Automated operation minimizes variability and manual handling mistakes.

- Compact and Lab-Friendly - Takes up minimal space while accommodating multiple sample containers.

- Orbital Shaking Motion - Moves samples in a circular path for uniform and consistent mixing.

- Variable Speed Control - Adjustable shaking speed (typically 50–300 RPM) to suit different sample types.

- Digital Timer - Programmable run time for precise and repeatable operations.

- Flat Platform Design - Accommodates flasks, beakers, tubes, or trays with optional clamps or non-slip mats.

- LCD or LED Display (in advanced models) - Shows speed, time, and operating status clearly.

- Quiet Operation - Low-noise motor and stable base minimize vibration and disturbance in the lab.

- Overload Protection - Prevents motor damage from excessive weight or resistance.

- Compact and Durable Build - Designed to fit standard lab benches and withstand regular use.

- Versatile Capacity Options - Available in various sizes to handle different numbers and sizes of containers. User-Friendly Interface - Simple control panel for easy setup and operation.

Brand: Dunlin

Origin: Korea.

Maximum. load capacity (with platform) is 7.5kg

Support orbital and linear shaking

Fashion design of high strength tempered glass on the front panel

LED display for easy-reading of speed and time simultaneously

Digital speed control system and micro-computer control make stable running and prevent sample splashing.

Brushless DC motor is maintenance-free and provides long service life

Over-load and over-speed detection and protection

Supports both orbital shaking and linear shaking and easy to switch the shaking mode

Continuous operation and timed operation in range of 0-99h59min are available

Automatic alarm by time controller allows for unsupervised operation

A wide choice of platforms for various applications

Orbital Shaker Machine Shaker Machine Dunlin price in Bangladesh

Orbital Shaker Machine Shaker Machine Dunlin in textile

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Shaker Machine Dunlin price in Bangladesh

Brand: Dunlin

Origin: Korea.

Maximum. load capacity (with platform) is 7.5kg

Support orbital and linear shaking

Fashion design of high strength tempered glass on the front panel

LED display for easy-reading of speed and time simultaneously

Digital speed control system and micro-computer control make stable running and prevent sample splashing.

Brushless DC motor is maintenance-free and provides long service life

Over-load and over-speed detection and protection

Supports both orbital shaking and linear shaking and easy to switch the shaking mode

Continuous operation and timed operation in range of 0-99h59min are available

Automatic alarm by time controller allows for unsupervised operation

A wide choice of platforms for various applications

Orbital Shaker Machine Shaker Machine Dunlin price in Bangladesh

Orbital Shaker Machine Shaker Machine Dunlin in textile

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Shaker Machine Dunlin price in Bangladesh Oscillation type water bath Dyeing Machine

Oscillation Type Water Bath Dyeing Machine

An Oscillation Type Water Bath Dyeing Machine is a laboratory apparatus designed for dyeing and washing textile samples under controlled temperature conditions. It combines a heated water bath with an oscillating mechanism to ensure uniform dye penetration and consistent coloration across fabric or yarn samples. Key Features of Oscillation Type Water Bath Dyeing Machine - Oscillating Mechanism: Provides back-and-forth movement to agitate the dye solution, ensuring even contact between the dye and the textile sample.- Multiple Beaker Capacity: Typically accommodates 12 to 24 beakers, allowing simultaneous processing of multiple samples under identical or varied conditions. - Digital Temperature Control: Maintains precise temperature settings, usually up to 99°C, suitable for various dyeing processes including atmospheric dyeing, scouring, and bleaching.- Adjustable Oscillation Speed: Offers variable speed settings, commonly ranging from 50 to 200 cycles per minute, to accommodate different fabric types and dyeing requirements. - Programmable Settings: Advanced models come with programmable controllers, allowing users to set and save multiple dyeing protocols for repeatability and efficiency. Durable Construction: Constructed with high-quality stainless steel (e.g., SUS304), ensuring resistance to corrosion and longevity even under rigorous laboratory conditions. ✅ Benefits of Oscillation Type Water Bath Dyeing Machine - Uniform Dyeing Results: The oscillation mechanism ensures consistent dye penetration, reducing the risk of uneven coloration and enhancing the reproducibility of results.- Efficiency in Sample Processing: The ability to process multiple samples simultaneously accelerates laboratory workflows and facilitates comparative studies. - Versatility: Suitable for a range of applications including dyeing, washing, scouring, bleaching, and fastness testing across various textile materials.- Energy and Resource Conservation: Designed for low liquor ratios (e.g., 1:5 to 1:20), these machines minimize water and chemical usage, promoting sustainable laboratory practices. - Enhanced Safety and Cleanliness: Enclosed beaker systems reduce the risk of spills and exposure to chemicals, ensuring a safer laboratory environment. Typical Applications of Oscillation Type Water Bath Dyeing Machine - Textile Research and Development: Ideal for developing and testing new dye formulations and processes on a small scale before scaling up to production levels. Quality Control: Used in quality assurance laboratories to assess color fastness, dye uptake, and other critical parameters of textile products.- Educational Purposes: Serves as a practical tool in academic settings for teaching dyeing principles and techniques. In summary, the Oscillation Type Water Bath Dyeing Machine is an essential tool in textile laboratories, offering precise control over dyeing parameters, improving efficiency, and ensuring high-quality, reproducible results across various textile materials. Features of Oscillation Type Water Bath Dyeing Machine:- Oscillating Mechanism - Provides back-and-forth movement of beakers for uniform dye penetration and sample agitation.

- Multiple Beaker Capacity - Supports dyeing of 12–24 samples simultaneously, ideal for comparative lab testing.

- Digital Temperature Control - Maintains precise water bath temperature (typically up to 99°C), essential for consistent dyeing.

- Variable Oscillation Speed - Adjustable speed settings (e.g., 50–200 cycles/min) to suit different materials and processes.

- Programmable Settings - Allows setting of temperature, time, and speed for repeatable and automated dyeing cycles.

- Stainless Steel Construction - Corrosion-resistant frame and bath for durability in chemical environments.

- Beaker Safety Holders - Secure placement of beakers to prevent spills and maintain consistent treatment.

- Compact Design - Lab-friendly size for easy integration into research and quality control spaces.

- Low Liquor Ratio Operation - Efficient dyeing using minimal dye bath volume (e.g., 1:5 to 1:20), reducing chemical and water use.

- Quiet and Stable Performance

water bath/Shaker bath Dyeing machine

Pantone book

Pantone Book

Pantone Book

- Formula Guide (Solid Coated & Uncoated) – For spot color printing.

- Color Bridge – Shows Pantone spot colors alongside CMYK equivalents.

- Pantone Fashion, Home + Interiors (FHI) – For textiles, soft goods, and home decor.

- Pantone CMYK and Pastels & Neons Guides – For process printing and special effect colors.

- Formula Guide (Solid Coated & Uncoated)

- Color Bridge Guide (Coated & Uncoated)

- CMYK Guide (Coated & Uncoated)

- Pastels & Neons Guide

- Metallics Guide

- FHI Color Guide (TPG – Paper)

- FHI Cotton Passport & Cotton Planner (TCX – Textile)

- FHI Polyester Swatch Book

- Pantone SkinTone Guide

- Pantone Plastic Standard Chips

Pantone Book

Perspiration Tester

Perspiration Tester

Perspiration Tester

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Stainless Steel Frame - Corrosion-resistant body for durability and long-term use.

- Multi-Sample Capacity - Can hold up to 20 or more specimens for batch testing.

- Standardized Loading Weight- Applies uniform pressure (usually 12.5 kPa) across all samples.

- Removable Plates - Glass or acrylic plates ensure even contact and easy cleaning.

- Compact Design- Space-saving, bench-top model ideal for lab environments.

- Complies with Test Standards - Meets ISO 105 E04, AATCC 15, and related perspiration fastness standards.

- Ease of Operation - Simple loading, unloading, and incubation process.

- High-Temperature Resistance - Can be used inside incubators at 37°C or ovens as required.

- Prepare the Test Solution - Mix artificial acidic or alkaline perspiration as per standard (ISO or AATCC).

- Cut the Fabric Samples - Cut both the test fabric and adjacent white fabric (usually cotton) to standard size.

- Soak the Samples - Immerse the fabric sandwich (test + adjacent) in the test solution for 30 minutes.

- Remove Excess Liquid - Gently squeeze or blot to remove extra moisture—do not dry.

- Load in the Tester- Place each sandwich between glass or acrylic separator plates in the tester.

- Apply Pressure - Tighten the top plate or place the standard weight on top to apply uniform pressure.

- Incubate - Keep the loaded tester in an oven or incubator at 37°C for 4–16 hours (depending on the method).

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Dry and Evaluate - Remove, air dry the samples, then assess color change and staining using a gray scale.

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

Perspiration Tester

Rainin Digital Pipette

Rainin Digital Pipette

Digital Pipette

- Digital Volume Setting

- High Accuracy and Precision

- Ergonomic Design

- Easy Calibration and Maintenance

- Durable and Chemically Resistant - Built with high-quality materials that resist damage from chemicals and frequent use.

- Models and Volume Ranges - Available in single-channel and multi-channel versions.

- LTS (LiteTouch System) - Many Rainin pipettes use the LTS tip system which reduces tip ejection force and ensures a consistent seal.

- Compliance and Traceability - Some digital models offer data storage or integration with lab information systems for traceability.

- High Accuracy and Precision - Ensures reliable and reproducible results, essential for sensitive experiments.

- Digital Volume Control - Reduces human error with easy and precise volume setting via digital interface.

- Ergonomic Design- Minimizes hand strain and fatigue during prolonged use; ideal for repetitive pipetting tasks.

- LiteTouch System (LTS) - Eases tip attachment and ejection, reducing risk of RSI (Repetitive Strain Injury) and improving comfort.

- Versatile Volume Range - Available in multiple models to handle volumes from microliters to milliliters.

- Durable and Reliable - Built with high-quality materials for long life and resistance to chemicals and frequent use.

- Easy Maintenance and Calibration - Simplified calibration and cleaning ensure long-term performance and compliance.

- Data Integrity and Traceability -Some models store data, supporting audit trails and regulatory compliance.

- Enhanced Productivity - Quick setup, easy operation, and consistent performance speed up lab workflows.

- Digital Volume Adjustment - Precise and easy-to-read digital display for accurate volume setting.

- High Precision and Accuracy- Delivers consistent results, meeting ISO and GLP/GMP standards.

- Ergonomic Design- Lightweight, balanced with low plunger and tip ejection force to reduce fatigue.

- LiteTouch Tip Ejection System (LTS) - Reduces tip attachment/ejection force, improving comfort and consistency.

- Durable Construction - Built with high-quality, chemically resistant materials for long-term use.

- Wide Volume Range - Available in multiple models from 0.1 µL to 10 mL.

- Single-Channel and Multi-Channel Options - Suitable for various applications including high-throughput assays.

- Autoclavable Components- Some parts can be autoclaved for sterilization and contamination control.

- Easy Calibration and Maintenance - User-friendly calibration settings with accessible parts for cleaning.

- Optional Electronic Models - Some versions include programmable features, multiple modes (e.g., reverse pipetting), and memory storage.

Random Tumble Pilling Tester

Random Tumble Pilling Tester

The Random Tumble Pilling Tester is a specialized instrument designed to assess the pilling resistance of textile fabrics. Pilling refers to the formation of small, fuzzy balls (pills) on the fabric surface due to wear and friction. This tester simulates the wear conditions that fabrics experience during actual use, providing valuable data on their durability and appearance retention. Purpose of Random Tumble Pilling Tester The primary function of the Random Tumble Pilling Tester is to evaluate how fabrics resist pilling, fuzzing, and matting. This assessment is crucial for manufacturers aiming to ensure the longevity and aesthetic quality of their textile products. Working Principle of Random Tumble Pilling Tester The tester operates by placing fabric specimens into cylindrical test chambers lined with cork. Inside each chamber, a stainless steel impeller rotates at a high speed (typically around 1200 revolutions per minute), causing the fabric samples to tumble randomly. Compressed air is injected to enhance the tumbling action. This process simulates the friction and wear that fabrics undergo during regular use. After a predetermined duration, the samples are removed and visually assessed for pilling using standardized rating scales. Key Specifications of Random Tumble Pilling Tester Test Chambers: Available in configurations of 2 or 4 chambers to accommodate multiple samples simultaneously. - Rotation Speed: Approximately 1200 revolutions per minute. - Chamber Dimensions: Typically around 146 mm in diameter and 152 mm in length. - Impeller Size: Standard impellers measuring about 121 mm. - Compressed Air Pressure: Adjustable, commonly between 14–21 kPa (2–3 psi). - Timer: Digital timer allowing precise control over test duration. - Power Supply: Generally operates on 220V, 50Hz power sources. Applicable Standards of Random Tumble Pilling Tester The Random Tumble Pilling Tester complies with several international testing standards, ensuring its suitability for global applications:- ASTM D3512- ISO 12945-3- DIN 53867- JIS L 1076- GB/T 4802.4 Benefits of Random Tumble Pilling Tester - Realistic Simulation: Accurately replicates the wear and friction conditions fabrics face during actual use.- Standardized Testing: Adheres to international standards, facilitating consistent and comparable results.- Efficient Evaluation: Allows simultaneous testing of multiple samples, increasing laboratory throughput.- Quality Assurance: Provides manufacturers with critical data to improve fabric formulations and production processes. User-Friendly Operation: Features intuitive controls and clear viewing windows for easy monitoring. Applications of Random Tumble Pilling Tester The Random Tumble Pilling Tester is widely used in various sectors of the textile industry: - Apparel Manufacturing: Assessing the durability of clothing fabrics. - Home Textiles: Evaluating materials used in upholstery, curtains, and bedding. - Quality Control Laboratories: Routine testing to ensure product consistency and compliance with standards.- Research and Development: Developing new fabrics with enhanced resistance to pilling. Features of Random Tumble Pilling Tester:- Multiple Test Chambers - Typically comes with 2 or 4 cork-lined chambers for simultaneous testing of multiple fabric samples.

- High-Speed Rotating Impellers - Impellers rotate at around 1200 rpm to create intense, random tumbling motion.

- Compressed Air System - Ensures continuous fabric movement and realistic simulation of wear.

- Digital Timer- Allows precise setting of test duration with easy-to-read display.

- Viewing Windows- Transparent chamber doors for monitoring fabric movement during testing.

- Standard Compliant Design- Meets ASTM D3512, ISO 12945-3, GB/T 4802.4 and other major standards.

- Robust Construction- Durable materials and components designed for long-term laboratory use.

- Easy Sample Handling - Quick-open chamber lids and simple sample placement process.

- Compact Footprint- Saves space in laboratory environments.

- Prepare Samples- Cut fabric into standard-sized specimens (usually circular or rectangular per ASTM/ISO specs)- Condition samples as per the standard (usually 24 hrs at 21°C, 65% RH).

- Load the Chambers - Place each sample into a cork-lined test chamber. - Add a small piece of gray cotton backing fabric if required by the method.

- Set Parameters - Adjust compressed air pressure (typically 14–21 kPa or 2–3 psi).

- Start the Test- Close the chamber doors and press start. - Impellers rotate, tumbling the samples randomly with air flow.

- Stop and Unload - Once the timer ends, remove the samples carefully.

- Evaluate Pilling - Compare the tested samples to standard pilling rating photographs or scales.

- Record Results - Document the pilling grades and any observations.

[Scope of application]:

It is used to test the fuzzing and pilling

performance of the fabric under the condition of

free rolling and friction in the drum.

[Related standards]:

GB/T4802.4 (Standard Drafting Unit)

ISO12945.3, ASTM D3512, ASTM D1375, DIN 53867, ISO 12945-3, JIS L1076, etc.

[Technical parameter]:

1. Number of boxes: 4

2. Roller specifications: diameter (146±1.0) mm, depth (152.4±1.0) mm;

3. Lining material: polychloroprene lining thickness (3.2±0.4) mm. , Hardness (60~70)

IRHD;

4. Impeller specifications: φ12.7 mm×120.6 mm;

5. Plastic blade specifications: 10 mm×65 mm;

6. Rotation speed: 1~2400 rpm can be set freely

7. Working pressure: 14kPa~21kPa;

8. Time counting: (1~999) min.

9. Power supply: AC220V±10% 50Hz 80W

10. Appearance: (480×400×680)mm

11. Weight: 40kg

[Standard accessories]

Items and specifications Qty. Note

Fuse 2 3A

Main machine 1

Power cable 1

Air tube 1 Φ8mm

Grey cotton sliver 4

Cork lining 4

Rating sample photo 1

White glue 1

[Scope of application]:

It is used to test the fuzzing and pilling

performance of the fabric under the condition of

free rolling and friction in the drum.

[Related standards]:

GB/T4802.4 (Standard Drafting Unit)

ISO12945.3, ASTM D3512, ASTM D1375, DIN 53867, ISO 12945-3, JIS L1076, etc.

[Technical parameter]:

1. Number of boxes: 4

2. Roller specifications: diameter (146±1.0) mm, depth (152.4±1.0) mm;

3. Lining material: polychloroprene lining thickness (3.2±0.4) mm. , Hardness (60~70)

IRHD;

4. Impeller specifications: φ12.7 mm×120.6 mm;

5. Plastic blade specifications: 10 mm×65 mm;

6. Rotation speed: 1~2400 rpm can be set freely

7. Working pressure: 14kPa~21kPa;

8. Time counting: (1~999) min.

9. Power supply: AC220V±10% 50Hz 80W

10. Appearance: (480×400×680)mm

11. Weight: 40kg

[Standard accessories]

Items and specifications Qty. Note

Fuse 2 3A

Main machine 1

Power cable 1

Air tube 1 Φ8mm

Grey cotton sliver 4

Cork lining 4

Rating sample photo 1

White glue 1

Sample Cone Yarn Dyeing machine

Sample Cone Yarn Dyeing Machine

Sample Cone Yarn Dyeing Machine

- Computer system: Foshan HuaGao Chinese English computer, equipped with LG PLC.

- Electromagnetic valve: Ningbo Jiaerling

- Frequency converter: Use Made in China frequency converters.

- Pump: self-made high head and large flow centrifugal water pump.

- Main pump motor: Anhui Wannan Motor.

- Master cylinder liquid level: Use 4-20mA analog signal output.

- Level of deputy temporary worker: use foam water level gauge. (American Mike)

- Temperature detection and display: digital temperature display instrument, dual temperature measuring probes.

- The safety system has a triple cylinder head safety interlock mechanism, and the main cylinder is equipped with a stainless

- steel safety valve.

- Heat exchanger: external spacer heating.

- Feeding system: Quantitative feeding based on the process curve.

- Circulation system: The main pump flows internally and externally, which is automatically controlled by a computer or manually controlled by a relay.

- Valves: Y valves are used for heating, stainless steel Y valves are used for single inlet and single row, and other Y valves are produced by joint ventures.

- Temperature control: on-off temperature control, controlled by a computer, with automatic heating, cooling, and insulation functions.

- Dyeing method: air cushion type.

- Opening method: manual opening.

- Surface treatment: polishing inside and outside the cylinder.

- Cage: Each dyeing machine is equipped with butterfly blades and self-locking locks.

- Body plate: high-quality stainless steel. (S31603)

- Bath ratio: 1:5-1:6

- Chemical material system: including heating and water adding functions, including overflow type salt melting device.

- Overflow cleaning: The cleaning port is installed on the upper part of the cylinder port, and the bottom of the cylinder is filled with water, while the cylinder is drained for easy cleaning.

- Commutation method: Novel "U" type commutation.

- Random accessories: Each model comes with one set of mechanical seals, pot mouth rings, and reversing seals for the main and auxiliary pumps.

Sample Cone Yarn Dyeing Machine

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated

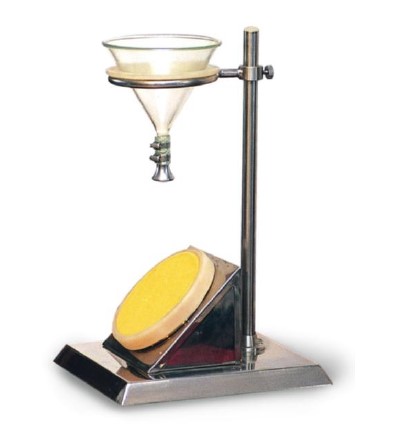

Spray Reting Tester

[Scope of application]:

Used for the determination of moisture resistance (wetting grade) of various fabrics

which have been or have not been treated with water resistance or water repellency.

[related standards]:

GB/T4745 ISO4920 AATCC22 JISL1092 etc.

[technical parameters]:

1. Glass funnel:150 x 150 (capacity 500ml)

2. Specimen placement angle:The level is 45 degrees.

3. Distance from nozzle to sample center:150mm

4. Specimen diameter:Ф150mm

5. Size of water receiving pan:500×400×30mm

6. Matching measuring cups:500ml

7, size 500 x 400 x 500mm

8. Instrument weight:5Kg

Spray Reting Tester

[Scope of application]:

Used for the determination of moisture resistance (wetting grade) of various fabrics

which have been or have not been treated with water resistance or water repellency.

[related standards]:

GB/T4745 ISO4920 AATCC22 JISL1092 etc.

[technical parameters]:

1. Glass funnel:150 x 150 (capacity 500ml)

2. Specimen placement angle:The level is 45 degrees.

3. Distance from nozzle to sample center:150mm

4. Specimen diameter:Ф150mm

5. Size of water receiving pan:500×400×30mm

6. Matching measuring cups:500ml

7, size 500 x 400 x 500mm

8. Instrument weight:5Kg