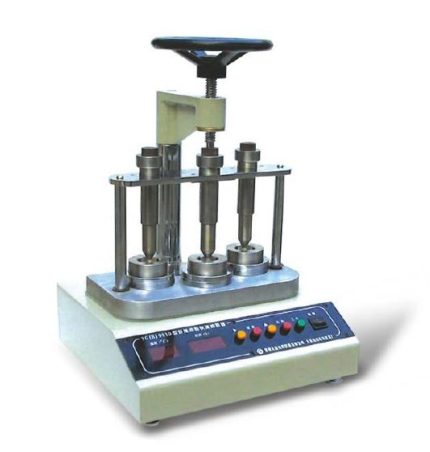

Random Tumble Pilling Tester

The Random Tumble Pilling Tester is a specialized instrument designed to assess the pilling resistance of textile fabrics. Pilling refers to the formation of small, fuzzy balls (pills) on the fabric surface due to wear and friction. This tester simulates the wear conditions that fabrics experience during actual use, providing valuable data on their durability and appearance retention.

Purpose of Random Tumble Pilling Tester

The primary function of the Random Tumble Pilling Tester is to evaluate how fabrics resist pilling, fuzzing, and matting. This assessment is crucial for manufacturers aiming to ensure the longevity and aesthetic quality of their textile products.

Working Principle of Random Tumble Pilling Tester

The tester operates by placing fabric specimens into cylindrical test chambers lined with cork. Inside each chamber, a stainless steel impeller rotates at a high speed (typically around 1200 revolutions per minute), causing the fabric samples to tumble randomly. Compressed air is injected to enhance the tumbling action. This process simulates the friction and wear that fabrics undergo during regular use. After a predetermined duration, the samples are removed and visually assessed for pilling using standardized rating scales.

Key Specifications of Random Tumble Pilling Tester

Test Chambers: Available in configurations of 2 or 4 chambers to accommodate multiple samples simultaneously.

– Rotation Speed: Approximately 1200 revolutions per minute.

– Chamber Dimensions: Typically around 146 mm in diameter and 152 mm in length.

– Impeller Size: Standard impellers measuring about 121 mm.

– Compressed Air Pressure: Adjustable, commonly between 14–21 kPa (2–3 psi).

– Timer: Digital timer allowing precise control over test duration.

– Power Supply: Generally operates on 220V, 50Hz power sources.

Applicable Standards of Random Tumble Pilling Tester

The Random Tumble Pilling Tester complies with several international testing standards, ensuring its suitability for global applications:- ASTM D3512- ISO 12945-3- DIN 53867- JIS L 1076- GB/T 4802.4

Benefits of Random Tumble Pilling Tester

– Realistic Simulation: Accurately replicates the wear and friction conditions fabrics face during actual use.- Standardized Testing: Adheres to international standards, facilitating consistent and comparable results.- Efficient Evaluation: Allows simultaneous testing of multiple samples, increasing laboratory throughput.- Quality Assurance: Provides manufacturers with critical data to improve fabric formulations and production processes. User-Friendly Operation: Features intuitive controls and clear viewing windows for easy monitoring.

Applications of Random Tumble Pilling Tester

The Random Tumble Pilling Tester is widely used in various sectors of the textile industry:

– Apparel Manufacturing: Assessing the durability of clothing fabrics.

– Home Textiles: Evaluating materials used in upholstery, curtains, and bedding.

– Quality Control Laboratories: Routine testing to ensure product consistency and compliance with standards.- Research and Development: Developing new fabrics with enhanced resistance to pilling.

Features of Random Tumble Pilling Tester:

- Multiple Test Chambers – Typically comes with 2 or 4 cork-lined chambers for simultaneous testing of multiple fabric samples.

- High-Speed Rotating Impellers – Impellers rotate at around 1200 rpm to create intense, random tumbling motion.

- Compressed Air System – Ensures continuous fabric movement and realistic simulation of wear.

- Digital Timer- Allows precise setting of test duration with easy-to-read display.

- Viewing Windows- Transparent chamber doors for monitoring fabric movement during testing.

- Standard Compliant Design- Meets ASTM D3512, ISO 12945-3, GB/T 4802.4 and other major standards.

- Robust Construction- Durable materials and components designed for long-term laboratory use.

- Easy Sample Handling – Quick-open chamber lids and simple sample placement process.

- Compact Footprint- Saves space in laboratory environments.

How to Use Random Tumble Pilling Tester:

- Prepare Samples- Cut fabric into standard-sized specimens (usually circular or rectangular per ASTM/ISO specs)- Condition samples as per the standard (usually 24 hrs at 21°C, 65% RH).

- Load the Chambers – Place each sample into a cork-lined test chamber. – Add a small piece of gray cotton backing fabric if required by the method.

- Set Parameters – Adjust compressed air pressure (typically 14–21 kPa or 2–3 psi).

– Set the test time (e.g., 30–60 minutes) using the digital timer.

- Start the Test- Close the chamber doors and press start. – Impellers rotate, tumbling the samples randomly with air flow.

- Stop and Unload – Once the timer ends, remove the samples carefully.

- Evaluate Pilling – Compare the tested samples to standard pilling rating photographs or scales.

– Assign a rating from 1 (severe pilling) to 5 (no pilling).

- Record Results – Document the pilling grades and any observations.

Random Tumble Pilling Tester

[Scope of application]:

It is used to test the fuzzing and pilling

performance of the fabric under the condition of

free rolling and friction in the drum.

[Related standards]:

GB/T4802.4 (Standard Drafting Unit)

ISO12945.3, ASTM D3512, ASTM D1375, DIN 53867, ISO 12945-3, JIS L1076, etc.

[Technical parameter]:

1. Number of boxes: 4

2. Roller specifications: diameter (146±1.0) mm, depth (152.4±1.0) mm;

3. Lining material: polychloroprene lining thickness (3.2±0.4) mm. , Hardness (60~70)

IRHD;

4. Impeller specifications: φ12.7 mm×120.6 mm;

5. Plastic blade specifications: 10 mm×65 mm;

6. Rotation speed: 1~2400 rpm can be set freely

7. Working pressure: 14kPa~21kPa;

8. Time counting: (1~999) min.

9. Power supply: AC220V±10% 50Hz 80W

10. Appearance: (480×400×680)mm

11. Weight: 40kg

[Standard accessories]

Items and specifications Qty. Note

Fuse 2 3A

Main machine 1

Power cable 1

Air tube 1 Φ8mm

Grey cotton sliver 4

Cork lining 4

Rating sample photo 1

White glue 1

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated

Scope of application

It is used to determine the moisture permeability of various fabrics

(including moisture permeable coated fabrics)

and nonwovens such as batting cotton and space cotton.

[Related standards] GB/T12704 ASTM E90 JIS L1099A BS 7209 JIS L1099B (custom) etc.

Instrument characteristics

1. Integrated structure of baking oven and constant temperature and humidity box.

2. Microcomputer control, color touch screen Chinese menu operation.

3. Circulating air velocity 0.2-3m/s digital setting.

4. Imported high-precision temperature and humidity sensor, imported motor drive, ceramic

heating tube heating.

Technical parameters

1.Work mode: Microcomputer control, color touch screen Chinese menu operation, test environment monitoring.

2. Sample box control temperature:15 ~ 40 C, accuracy 0.1 + C, resolution 0.01 C

3. Heat dissipation mode:Air cooling

4. Sample box control humidity:30 ~ 95%, precision + 2%, resolution 0.01%

5. Test chamber humidification:≥300ml/h

6. Accompany oven control temperature: Room temperature to 200 c

7. Test time:1min~999h59min

8. The rate of circulating steam flow:0. 2-3m/s digital setting resolution 0.01m/s

9. Moisture permeability area:2827㎜2(∮60㎜GB)

Optional 3848, 2 (70 70 ASTM)

10. The number of moisture permeable cups.6 (GB) can be replaced by 6 (US standard).

11. Internal dimensions of drying oven:490×400×215mm

12. Power supply:Ac220V 50Hz 6kw

13. Size:930×820×1700mm

14. Weight:350kg

Scope of application

It is used to determine the moisture permeability of various fabrics

(including moisture permeable coated fabrics)

and nonwovens such as batting cotton and space cotton.

[Related standards] GB/T12704 ASTM E90 JIS L1099A BS 7209 JIS L1099B (custom) etc.

Instrument characteristics

1. Integrated structure of baking oven and constant temperature and humidity box.

2. Microcomputer control, color touch screen Chinese menu operation.

3. Circulating air velocity 0.2-3m/s digital setting.

4. Imported high-precision temperature and humidity sensor, imported motor drive, ceramic

heating tube heating.

Technical parameters

1.Work mode: Microcomputer control, color touch screen Chinese menu operation, test environment monitoring.

2. Sample box control temperature:15 ~ 40 C, accuracy 0.1 + C, resolution 0.01 C

3. Heat dissipation mode:Air cooling

4. Sample box control humidity:30 ~ 95%, precision + 2%, resolution 0.01%

5. Test chamber humidification:≥300ml/h

6. Accompany oven control temperature: Room temperature to 200 c

7. Test time:1min~999h59min

8. The rate of circulating steam flow:0. 2-3m/s digital setting resolution 0.01m/s

9. Moisture permeability area:2827㎜2(∮60㎜GB)

Optional 3848, 2 (70 70 ASTM)

10. The number of moisture permeable cups.6 (GB) can be replaced by 6 (US standard).

11. Internal dimensions of drying oven:490×400×215mm

12. Power supply:Ac220V 50Hz 6kw

13. Size:930×820×1700mm

14. Weight:350kg

Scope of application

It is used to measure the stiffness of cotton,

wool, silk, linen, chemical fibers and other woven fabrics,

knitted fabrics, general nonwovens, coated fabrics, etc.

It is also suitable for measuring the stiffness of paper,

leather, film and other flexible materials.

Relevant Standards

GB/T 18318, ASTM D 1388, IS09073-7, BS EN22313 etc.

[Instrument Characteristics]

1. Infrared photoelectric invisible inclined plane

detection system replaces the traditional tangible inclined plane,

realizes non-contact detection, and overcomes the problem that

the measurement accuracy is affected by

the sample torsion lifted by the inclined plane.

2. The inclination adjustable mechanism of instrument

measurement to meet different test requirements.

3. Stepping motor drive, accurate measurement, smooth operation;

4. The color touch screen display can show the extended length,

bending length, bending stiffness of the sample, the warp average,

the weft average and the total average of the above values respectively.

5. Printing of Chinese report forms for thermal printers.

Technical parameters

1. Test methods: The two method (A method: Weft test, B method: Forward and backward test)

2. Measurement angle:41.5 degree, 43 degree and 45 degree adjustable

3. Extend the length range:5-220 mm (special requirements can be made at the time of ordering)

4. Length resolution:0.01mm

5. Measurement accuracy:±0.1mm

6. Specimen specifications:250×25mm

7. Work platform specifications:250×50mm

8. Specification of sample pressing plate:250×25mm

9. Pushing speed of press plate:3 mm/s; 4 mm/s; 5 mm/s

10. Display output: Touch screen display

11. Print Output: Chinese Report

12. Data Processing Volume: A total of 15 groups, each group less than 20 trials

13. Printer: Thermal printer

14, power supply:AC220V 50Hz

15. Host volume:570mm×360mm×490mm

16. Host weight:20kg

Scope of application

It is used to measure the stiffness of cotton,

wool, silk, linen, chemical fibers and other woven fabrics,

knitted fabrics, general nonwovens, coated fabrics, etc.

It is also suitable for measuring the stiffness of paper,

leather, film and other flexible materials.

Relevant Standards

GB/T 18318, ASTM D 1388, IS09073-7, BS EN22313 etc.

[Instrument Characteristics]

1. Infrared photoelectric invisible inclined plane

detection system replaces the traditional tangible inclined plane,

realizes non-contact detection, and overcomes the problem that

the measurement accuracy is affected by

the sample torsion lifted by the inclined plane.

2. The inclination adjustable mechanism of instrument

measurement to meet different test requirements.

3. Stepping motor drive, accurate measurement, smooth operation;

4. The color touch screen display can show the extended length,

bending length, bending stiffness of the sample, the warp average,

the weft average and the total average of the above values respectively.

5. Printing of Chinese report forms for thermal printers.

Technical parameters

1. Test methods: The two method (A method: Weft test, B method: Forward and backward test)

2. Measurement angle:41.5 degree, 43 degree and 45 degree adjustable

3. Extend the length range:5-220 mm (special requirements can be made at the time of ordering)

4. Length resolution:0.01mm

5. Measurement accuracy:±0.1mm

6. Specimen specifications:250×25mm

7. Work platform specifications:250×50mm

8. Specification of sample pressing plate:250×25mm

9. Pushing speed of press plate:3 mm/s; 4 mm/s; 5 mm/s

10. Display output: Touch screen display

11. Print Output: Chinese Report

12. Data Processing Volume: A total of 15 groups, each group less than 20 trials

13. Printer: Thermal printer

14, power supply:AC220V 50Hz

15. Host volume:570mm×360mm×490mm

16. Host weight:20kg