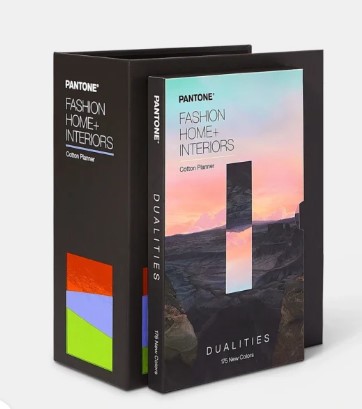

Pantone book

$0.00

Pantone Book

Pantone Book

A Pantone Book, commonly referred to as a Pantone Color Guide, is a professional color matching tool used across industries like graphic design, fashion, printing, packaging, and product manufacturing. It helps ensure consistent color communication from design to final production.

What It Does?

– Displays standardized Pantone colors in fan-deck or chip book format.

– Provides color codes, ink formulas, and finish types for accurate color replication.

Types of Pantone Books:

- Formula Guide (Solid Coated & Uncoated) – For spot color printing.

- Color Bridge – Shows Pantone spot colors alongside CMYK equivalents.

- Pantone Fashion, Home + Interiors (FHI) – For textiles, soft goods, and home decor.

- Pantone CMYK and Pastels & Neons Guides – For process printing and special effect colors.

⚙️ Features of Pantone Book:

– Thousands of pre-defined colors.

– Ink mixing formulas (for printers).

– Available in coated, uncoated, and matte finishes.

– Some include digital tools or access to Pantone Connect software.

✅ Benefits of Pantone Book:

– Ensures accurate color matching across designers, clients, and manufacturers.

– Supports branding consistency across all printed and physical materials.

key benefits of using a Pantone Book:

✅ 1. Accurate Color Communication- Ensures consistent color matching between designers, printers, and manufacturers—globally.

✅ 2. Industry Standard- Trusted across printing, fashion, packaging, and branding for reliable color references.

✅ 3. Saves Time and Reduces Errors – Eliminates guesswork in color approval, helping avoid costly reprints or corrections.

✅ 4. Versatile Applications – Supports multiple media types: print, fabric, plastics, digital design, etc.

✅ 5. Real-World Color View – Physical swatches show true ink or dye appearance, which digital screens can’t replicate accurately.

✅ 6. Ink Mixing Formulas – Provides exact mixing guides for printers to replicate spot colors precisely.

✅ 7. Global Consistency – Helps maintain brand color consistency across international production sites.

key features of a Pantone Book:

1. Standardized Color System – Includes thousands of pre-defined Pantone Matching System (PMS) colors with unique codes.

2. Multiple Finish Types – Available in Coated (C), Uncoated (U), Matte (M) formats to match different printing surfaces.

3. Fan Deck or Chip Format – Comes in portable fan-deck or tear-away chip books for easy reference and sharing.

4. Ink Mixing Formulas – Provides precise ink formulas for each color, ideal for print production.

5. Specialized Editions – Guides tailored for graphic design, textiles (FHI), plastics, and digital design.

6. Cross-Media Consistency – Ensures uniform color across print, web, fabric, and packaging.

7. Digital Integration – Many books include access to Pantone Connect for digital workflow and color data sync.

Here’s a simple guide on how to use a Pantone Book effectively:

✅ 1. Choose the Right Pantone Book

– Use Formula Guide for print.

– Use FHI (Fashion, Home + Interiors) for textiles.

– Use Color Bridge to compare spot colors with CMYK.

✅ 2. Select the Color

– Flip through the fan deck or chip book to find the desired color.

– Note the Pantone code (e.g., Pantone 186 C for coated paper).

✅ 3. Communicate the Code

– Share the Pantone number with printers, manufacturers, or team members to ensure consistent color use.

✅ 4. Use the Right Finish – Make sure you’re referencing coated, uncoated, or matte depending on your final material.

✅ 5. Compare to Printed Proofs

– Use the physical Pantone swatch to check if print proofs or samples match.

✅ 6. Maintain Lighting Consistency

– View colors under standard lighting (D50) for accurate color judgment.

✅ 7. Store Properly – Keep the Pantone book in a cool, dry place and replace it every 12–18 months to avoid fading.

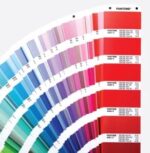

Pantone offers a diverse range of color guides tailored to various industries and applications. Here’s an overview of the main Pantone book models:

Pantone Graphics & Print Guides

- Formula Guide (Solid Coated & Uncoated)

– Features over 2,390 spot colors with corresponding ink formulations.

– Essential for branding, packaging, and print design.

– Provides accurate color matching for solid colors.

- Color Bridge Guide (Coated & Uncoated)

– Displays side-by-side comparisons of Pantone spot colors and their closest CMYK equivalents.

– Includes CMYK, RGB, and HEX values for digital and print consistency.

– Ideal for projects requiring color translation across different media.

- CMYK Guide (Coated & Uncoated)

– Contains a comprehensive range of CMYK colors.

– Useful for four-color process printing without spot colors.

– Helps in selecting colors achievable through standard CMYK printing.

- Pastels & Neons Guide

– Offers a collection of soft pastel and vibrant neon colors.

– Suitable for creative projects in fashion, print, and packaging.

– Provides unique color options for special design applications.

- Metallics Guide

– Features metallic spot colors for premium print finishes.

Ideal for luxury packaging, branding, and high-end print materials.

– Adds a sophisticated touch to printed designs.

Pantone Fashion, Home + Interiors (FHI) Guides

- FHI Color Guide (TPG – Paper)

– Contains a wide range of colors for non-fabric materials.

– Used in product design, cosmetics, and interiors.

– Provides color inspiration for various applications.

- FHI Cotton Passport & Cotton Planner (TCX – Textile)

– Offers colors on cotton fabric swatches.

– Essential for textile and apparel design.

– Ensures accurate color communication in fabric production.

- FHI Polyester Swatch Book

– Includes colors on polyester fabric.

– Useful for sportswear, footwear, and synthetic textiles.

– Provides color options specific to polyester materials.

Pantone Specialty Guides

- Pantone SkinTone Guide

– Features a range of skin tone colors.

– Used in cosmetics, healthcare, and product development.

– Aids in creating products that match diverse skin tones.

- Pantone Plastic Standard Chips

– Provides color references on plastic substrates.

– Essential for industrial design, consumer electronics, and appliances.

– Ensures color accuracy in plastic product manufacturing.

Pantone Bundles & Studio Sets

– Portable Guide Studio

– A comprehensive set including multiple Pantone guides.

– Designed for professionals needing a wide range of color references.

– Convenient for on-the-go color selection and matching.

– Essentials Set

– Combines key Pantone guides into one package.

– Ideal for designers seeking a versatile color toolkit.

– Offers a cost-effective solution for comprehensive color needs.

Each Pantone guide serves specific purposes across different industries. Selecting the appropriate guide depends on your project’s requirements and the materials involved.

Pantone Book

Related products

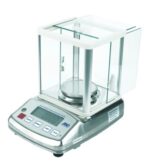

Digital precision balance

digital precision balance

2/3/4/5 Digit Digital precision Balance

digital precision balance is a weight balance machine. It’s used to Low capacity balance. digital precision balance play an important role to accurate measurement. Digital precision balance is used to check weight paper, jewelry etc. It shows accurate result. We have the best collection of digital precision balance. MAAM TEX IS the best supplier of Precision Balance in Bangladesh

A Digital Precision Balance is a high-accuracy electronic weighing device used in laboratories, industries, and educational institutions for measuring mass with a high degree of precision. It is essential for tasks that require meticulous weight measurements, such as chemical analysis, formulation, and quality control. Key Features:- High Accuracy & Precision: - Typically offers readability from 0.1 g to 0.001 g (or even finer). - Ideal for weighing small amounts of material where accuracy is crucial.

- Digital Display: - Large, backlit LCD or LED display for easy reading. - Some models include touch screen interfaces.

- Tarring Function: - Allows you to subtract the weight of a container or packaging to get the net weight.

- Calibration: - Internal or external calibration to maintain accuracy over time. - Some advanced models have auto-calibration features.

- Weighing Units: - Supports multiple units like grams (g), milligrams (mg), carats (ct), and ounces (oz). Stable Platform: - Includes a draft shield to protect against air currents and vibrations, which can affect measurement accuracy.

- High Accuracy and Precision- Delivers extremely accurate weight measurements, often down to 0.001 g or better.- Crucial for experiments and applications where even slight variations can affect outcomes.

- User-Friendly Interface- Digital display makes readings easy to read and interpret.- Most models include intuitive controls for functions like tarring, unit conversion, and calibration.3. Speed and Efficiency- Provides instant, stable readings, saving time compared to manual or mechanical balances.- Streamlines lab workflows and enhances productivity.

- Versatile Applications- Suitable for various fields including chemistry, biology, pharmacology, food testing, and gemology.- Can handle diverse weighing tasks from solids to liquids and powders.

- Advanced Features- Tare Function: Subtracts the weight of containers automatically.- Multiple Weighing Units: Supports various measurement units.- Data Connectivity: Many models allow connection to computers or printers for data logging.

- Portability and Space Efficiency- Compact design fits easily in most laboratory setups.- Lightweight models are easy to move and store.

- Enhanced Safety and Reliability- Stable platform and draft shields reduce environmental interference.- Built-in calibration ensures ongoing accuracy.

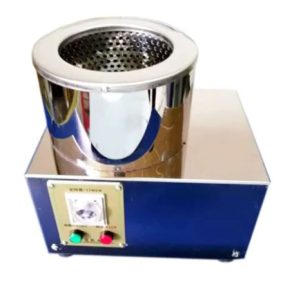

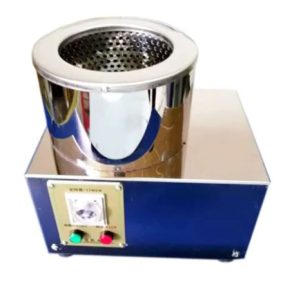

Laboratory hydro Extractor

Laboratory Hydro Extractor

A Laboratory Hydro Extractor is a compact, high-speed centrifuge used in textile labs to remove excess water from fabric or yarn samples after dyeing or washing. It works on the principle of centrifugal force, efficiently reducing moisture content before drying. Key Features:- Centrifugal Water Extraction - Uses high-speed spinning (typically 1400–2800 RPM) to extract water from textiles.

- Stainless Steel Inner Basket - Perforated drum holds fabric/yarn securely and allows water to drain efficiently.

- Compact Lab Design - Space-saving unit designed specifically for laboratory sample sizes.

- Digital Timer and Speed Control - Allows precise setting of spin duration and RPM to match sample needs.

- Safety Lock System - Ensures the lid remains closed during operation for user safety.

- Quick Water Removal - Significantly reduces drying time by extracting up to 90–95% of water content.

- Low Noise and Vibration - Balanced design ensures quiet and stable operation.

- Efficient Water Removal - Rapidly extracts 90–95% of water from samples, reducing drying time significantly.

- Saves Time and Energy - Cuts down the load on dryers and shortens total processing time in lab workflows.

- Improves Sample Quality - Gentle spinning preserves fabric structure, avoiding damage or distortion.

- Precise Control - Adjustable speed and timer ensure optimal settings for different fabric types.

- Compact and Lab-Friendly - Small footprint ideal for laboratory use with limited space.

- User Safety - Safety lock prevents lid opening during operation, protecting the user.

- Cost-Effective - Reduces the need for extended dryer use, saving on electricity and equipment wear.

- Versatile Use - Suitable for yarn, fabric, and garment samples across various fiber types.

- High-Speed Centrifugal Operation - Typically runs at 1400–2800 RPM for quick and efficient water removal.

- Stainless Steel Inner Drum - Corrosion-resistant, perforated basket for durability and efficient water drainage.

- Digital Timer and Speed Control - Allows precise control of spin duration and speed based on sample type.

- Compact and Portable Design - Ideal for lab environments with limited space.

- Safety Lock Mechanism - Prevents the lid from opening while the machine is in operation.

- Shock Absorption System- Reduces vibration and noise for smooth, stable performance.

- Quick Cycle Times - Short dewatering cycles improve lab throughput and efficiency.

- Low Maintenance Design - Simple mechanical setup with easy-to-clean components.

- Sample Versatility - Suitable for small fabric swatches, yarns, and small garments.

- Energy Efficient - Uses minimal power while delivering high performance.

- Prepare the Sample - After dyeing or washing, gently squeeze excess water from the fabric or yarn sample by hand.

- Load the Sample - Open the lid and place the sample evenly in the stainless steel drum. - Avoid overloading or uneven placement to maintain balance.

- Close the Lid securely - Ensure the safety lid is properly closed and locked.

- Set the Timer and Speed - Use the control panel to set the spin time (typically 1–5 minutes) and RPM suitable for the sample type.

- Start the Machine- Press the start button. The extractor will spin at the selected speed to remove water via centrifugal force.

- Wait for Spin Completion - The machine will automatically stop after the timer runs out.

- Unload the Sample - Once the drum stops completely, open the lid and carefully remove the sample.

- Proceed to Drying - The dewatered sample can now be air-dried or placed in a drying oven or stenter.

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Laboratory hydro Extractor Machine Dunlin price in Bangladesh Laboratory hydro Extractor Machine Dunlin in textile Textile testing equipment in Bangladesh Textile testing equipment in Dhaka Textile testing equipment in Uttara MAAM tex Laboratory hydro Extractor Machine Dunlin price in Bangladesh

Laboratory hydro ExtractorController For IR Dyeing Machine

Controller For IR Dyeing Machine

IR Dyeing machine controller

- Temperature Control:- Precisely regulates the infrared heaters to maintain uniform temperature across the dye bath. - Supports customizable heating curves (ramp-up, hold, and cool-down phases).

- Programmable Logic Control (PLC): - Allows operators to set and automate dyeing programs for different fabrics and dye types. - Supports multiple recipes or programs for different batches.

- Real-Time Monitoring and Feedback: - Monitors parameters like temperature, fabric rotation, bath circulation, and timing. - Provides real-time data and alarms for deviations.

- Touchscreen Interface / HMI (Human Machine Interface): - User-friendly interface for configuring and monitoring processes. - Multi-language support and graphical display of process curves.

- Data Logging and Traceability: - Records process data for quality control and traceability.

- Energy Efficiency Optimization: - Manages IR heater output to reduce energy usage. - Often includes features for auto shut-off or idle mode.

- Safety Features: - Includes emergency stop, over-temperature protection, and fault detection systems. 8. Connectivity: - Modern controllers may support Ethernet, Modbus, or other industrial communication protocols for integration into factory automation systems.

- Improved Dyeing Accuracy and Consistency

- Enhanced Energy Efficiency- Infrared heating is more energy-efficient than traditional heating methods.- The controller optimizes energy use by adjusting the IR output based on process needs, reducing overall energy consumption.

- Time Savings- Faster heating and cooling cycles due to infrared technology.- Automated processes reduce manual intervention and cycle times. 4. Better Process Control- Programmable dyeing cycles and precise control over each stage (heating, dyeing, rinsing, cooling).- Real-time monitoring and adjustments improve reliability.

- Reduced Water and Chemical Usage- More efficient dye penetration and fixation mean less water and fewer chemicals are needed for reprocessing or corrections.6. Lower Operational Costs

- Enhanced Safety Built-in alarms, emergency shut-off and automatic fault detection enhance operational safety.8. Data Logging and Traceability- Ability to record and review dyeing process data helps in quality control and troubleshooting.- Facilitates compliance with industry standards and audits.

- User-Friendly Operation- Modern touchscreen interfaces make it easier for operators to manage and monitor processes.- Multilingual support and visual feedback enhance usability.

Laboratory tenter

Laboratory Tenter

A Laboratory Tenter (or Lab Stenter) is a small-scale version of an industrial tenter machine used in textile finishing. It is designed for heat-setting, drying, and finishing of fabric samples under controlled conditions in textile testing labs or R&D departments. Key Features:- Heat-Setting and Drying - Simulates the process of setting fabric dimensions and applying finishes using controlled temperature and tension.

- Fabric Width Control - Uses clips or pins on chains or rails to hold fabric edges and stretch them to desired width, just like in full-size tenters.

- Adjustable Temperature and Speed - Digital controls allow precise setting of drying/curing temperature and conveyor speed to match production conditions.

- Compact Design - Bench-top or floor-standing units suitable for labs with limited space.

- Transparent Viewing Chamber - Allows visual inspection of fabric behavior during processing.

- Versatile Application Range - Can process woven, knitted, and nonwoven fabrics of various compositions (cotton, polyester, blends, etc.).

- Accurate Simulation of Production - Replicates industrial finishing processes for reliable lab-scale testing and development.

- Improves Fabric Quality- Allows precise control of heat and tension, optimizing fabric properties like shrinkage, dimensional stability, and hand feel.

- Cost-Effective - Enables process trials and fabric development without using full-scale production equipment.

- Speeds Up R&D - Facilitates quick testing and adjustment of settings for new fabric styles or finishes.

- Versatile Applications - Suitable for drying, heat-setting, finishing, and evaluating different types of fabrics and treatments.

- Space-Efficient - Compact design fits easily into textile labs or sample rooms.

- Energy Efficient- Uses less power than industrial machines, ideal for small-scale and repeated testing.

- Process Control and Reproducibility- Digital controls ensure consistent and repeatable results, aiding in quality assurance and product development.

- Enhances Safety - Built with lab use in mind, featuring insulation and safety systems to protect users.

- Precise Temperature Control - Digital temperature setting (typically up to 220–250°C) for accurate heat-setting and drying.

- Adjustable Fabric Width - Equipped with clip or pin chains to hold and stretch fabric across the width, simulating real stentering.

- Variable Conveyor or Chain Speed- Adjustable speed to control fabric dwell time during processing.

- Compact and Lab-Friendly Design - Designed for bench-top or small floor space use in textile labs.

- Transparent Chamber Window - Allows monitoring of fabric behavior during treatment.

- Digital Display and Control Panel - Easy operation for setting temperature, speed, and time.

- Uniform Heat Distribution- Ensures even treatment across the fabric width for accurate testing.

- Stainless Steel Construction - Durable, corrosion-resistant body for long-term use at high temperatures.

- Safety Features - Includes over-temperature protection, insulated body, and emergency stop functions.

- Sample Versatility - Suitable for various fabric types (woven, knit, synthetic, blends) and lab finishing tasks.

laboratory mini tenter

Stretch Recovery Tester Static Method

Stretch Recovery Tester Static Method

Stretch Recovery Tester

- A sample is stretched to a predetermined extension or force.

- The stretch is maintained for a set period.

- After removing the load, the recovery (return to original length) is measured after a fixed time.

- The fabric sample is clamped and stretched to a specific length or force.

- It’s held for a fixed duration (e.g., 1–5 minutes).

- The tension is released, and the sample is allowed to recover.

- The recovered length is measured after a set time.

Stretch Recovery Tester

Oscillation type water bath Dyeing Machine

Oscillation Type Water Bath Dyeing Machine

An Oscillation Type Water Bath Dyeing Machine is a laboratory apparatus designed for dyeing and washing textile samples under controlled temperature conditions. It combines a heated water bath with an oscillating mechanism to ensure uniform dye penetration and consistent coloration across fabric or yarn samples. Key Features of Oscillation Type Water Bath Dyeing Machine - Oscillating Mechanism: Provides back-and-forth movement to agitate the dye solution, ensuring even contact between the dye and the textile sample.- Multiple Beaker Capacity: Typically accommodates 12 to 24 beakers, allowing simultaneous processing of multiple samples under identical or varied conditions. - Digital Temperature Control: Maintains precise temperature settings, usually up to 99°C, suitable for various dyeing processes including atmospheric dyeing, scouring, and bleaching.- Adjustable Oscillation Speed: Offers variable speed settings, commonly ranging from 50 to 200 cycles per minute, to accommodate different fabric types and dyeing requirements. - Programmable Settings: Advanced models come with programmable controllers, allowing users to set and save multiple dyeing protocols for repeatability and efficiency. Durable Construction: Constructed with high-quality stainless steel (e.g., SUS304), ensuring resistance to corrosion and longevity even under rigorous laboratory conditions. ✅ Benefits of Oscillation Type Water Bath Dyeing Machine - Uniform Dyeing Results: The oscillation mechanism ensures consistent dye penetration, reducing the risk of uneven coloration and enhancing the reproducibility of results.- Efficiency in Sample Processing: The ability to process multiple samples simultaneously accelerates laboratory workflows and facilitates comparative studies. - Versatility: Suitable for a range of applications including dyeing, washing, scouring, bleaching, and fastness testing across various textile materials.- Energy and Resource Conservation: Designed for low liquor ratios (e.g., 1:5 to 1:20), these machines minimize water and chemical usage, promoting sustainable laboratory practices. - Enhanced Safety and Cleanliness: Enclosed beaker systems reduce the risk of spills and exposure to chemicals, ensuring a safer laboratory environment. Typical Applications of Oscillation Type Water Bath Dyeing Machine - Textile Research and Development: Ideal for developing and testing new dye formulations and processes on a small scale before scaling up to production levels. Quality Control: Used in quality assurance laboratories to assess color fastness, dye uptake, and other critical parameters of textile products.- Educational Purposes: Serves as a practical tool in academic settings for teaching dyeing principles and techniques. In summary, the Oscillation Type Water Bath Dyeing Machine is an essential tool in textile laboratories, offering precise control over dyeing parameters, improving efficiency, and ensuring high-quality, reproducible results across various textile materials. Features of Oscillation Type Water Bath Dyeing Machine:- Oscillating Mechanism - Provides back-and-forth movement of beakers for uniform dye penetration and sample agitation.

- Multiple Beaker Capacity - Supports dyeing of 12–24 samples simultaneously, ideal for comparative lab testing.

- Digital Temperature Control - Maintains precise water bath temperature (typically up to 99°C), essential for consistent dyeing.

- Variable Oscillation Speed - Adjustable speed settings (e.g., 50–200 cycles/min) to suit different materials and processes.

- Programmable Settings - Allows setting of temperature, time, and speed for repeatable and automated dyeing cycles.

- Stainless Steel Construction - Corrosion-resistant frame and bath for durability in chemical environments.

- Beaker Safety Holders - Secure placement of beakers to prevent spills and maintain consistent treatment.

- Compact Design - Lab-friendly size for easy integration into research and quality control spaces.

- Low Liquor Ratio Operation - Efficient dyeing using minimal dye bath volume (e.g., 1:5 to 1:20), reducing chemical and water use.

- Quiet and Stable Performance

water bath/Shaker bath Dyeing machine

Rainin Digital Pipette

Rainin Digital Pipette

Digital Pipette

- Digital Volume Setting

- High Accuracy and Precision

- Ergonomic Design

- Easy Calibration and Maintenance

- Durable and Chemically Resistant - Built with high-quality materials that resist damage from chemicals and frequent use.

- Models and Volume Ranges - Available in single-channel and multi-channel versions.

- LTS (LiteTouch System) - Many Rainin pipettes use the LTS tip system which reduces tip ejection force and ensures a consistent seal.

- Compliance and Traceability - Some digital models offer data storage or integration with lab information systems for traceability.

- High Accuracy and Precision - Ensures reliable and reproducible results, essential for sensitive experiments.

- Digital Volume Control - Reduces human error with easy and precise volume setting via digital interface.

- Ergonomic Design- Minimizes hand strain and fatigue during prolonged use; ideal for repetitive pipetting tasks.

- LiteTouch System (LTS) - Eases tip attachment and ejection, reducing risk of RSI (Repetitive Strain Injury) and improving comfort.

- Versatile Volume Range - Available in multiple models to handle volumes from microliters to milliliters.

- Durable and Reliable - Built with high-quality materials for long life and resistance to chemicals and frequent use.

- Easy Maintenance and Calibration - Simplified calibration and cleaning ensure long-term performance and compliance.

- Data Integrity and Traceability -Some models store data, supporting audit trails and regulatory compliance.

- Enhanced Productivity - Quick setup, easy operation, and consistent performance speed up lab workflows.

- Digital Volume Adjustment - Precise and easy-to-read digital display for accurate volume setting.

- High Precision and Accuracy- Delivers consistent results, meeting ISO and GLP/GMP standards.

- Ergonomic Design- Lightweight, balanced with low plunger and tip ejection force to reduce fatigue.

- LiteTouch Tip Ejection System (LTS) - Reduces tip attachment/ejection force, improving comfort and consistency.

- Durable Construction - Built with high-quality, chemically resistant materials for long-term use.

- Wide Volume Range - Available in multiple models from 0.1 µL to 10 mL.

- Single-Channel and Multi-Channel Options - Suitable for various applications including high-throughput assays.

- Autoclavable Components- Some parts can be autoclaved for sterilization and contamination control.

- Easy Calibration and Maintenance - User-friendly calibration settings with accessible parts for cleaning.

- Optional Electronic Models - Some versions include programmable features, multiple modes (e.g., reverse pipetting), and memory storage.

Laboratory mini stenter Dryer

Laboratory mini stenter Dryer

A Laboratory Mini Stenter Dryer is a compact, lab-scale machine designed to simulate the drying and heat-setting processes used in textile finishing. It mimics the function of industrial stenter machines but on a much smaller scale, making it ideal for testing fabric behavior, shrinkage, and finish quality under controlled conditions. Key Features:- Controlled Heating System

- Adjustable Fabric Width

- Variable Speed Conveyor - Allows control over fabric dwell time for drying or heat-setting.

- Compact and Bench-Top Design - Space-saving design ideal for textile labs and R&D units.

- Digital Controls - Easy-to-use digital interface for setting temperature, conveyor speed, and process time.

- Transparent Viewing Window - Allows operators to monitor fabric movement and drying visually.

- Low Energy Consumption - Designed for lab use, consuming less power than industrial models.

- Accurate Simulation of Production - Mimics industrial stenter conditions on a lab scale, ideal for pre-production testing and R&D.

- Cost-Effective Testing - Enables testing and fabric finishing without the high cost or space requirements of full-scale machines.

- Energy Efficient - Consumes less power compared to large stenters, making it economical for small-scale or frequent use.

- Precise Control - Offers accurate control of temperature, speed, and fabric tension, ensuring consistent results.

- Space-Saving Design - Compact and bench-top friendly, perfect for laboratories with limited space.

- Multiple Applications - Useful for drying, heat-setting, shrinkage testing, and evaluating chemical finishes.

- Faster Development Cycles - Speeds up new product development by allowing rapid sample testing and adjustments.

- Improved Fabric Quality - Helps optimize finishing parameters for better dimensional stability, hand feel, and appearance.

- Safe and User-Friendly- Designed with lab safety in mind, including temperature safety controls and easy operation.

- Compact Bench-Top Design - Ideal for laboratory use with limited space requirements.

- Adjustable Temperature Control - Precise heating (usually up to 220–250°C) with digital controllers for accurate processing.

- Variable Conveyor Speed- Allows adjustment of fabric dwell time for different drying or heat-setting needs.

- Width Adjustment Mechanism - Equipped with clips or pins to stretch and fix fabric width-wise, simulating industrial stenter conditions.

- Transparent Viewing Window - Enables visual monitoring of fabric movement and drying inside the chamber.

- Digital Display Panel- Easy-to-use interface for setting and monitoring temperature, speed, and time.

- Stainless Steel Construction- Durable and corrosion-resistant for long-term use at high temperatures.

- Uniform Heat Distribution- Ensures consistent fabric treatment across the width.

- Safety Features- Over-temperature protection and insulated body for operator safety.

- Versatile Applications - Suitable for drying, heat-setting, shrinkage testing, and chemical finish evaluations.

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated