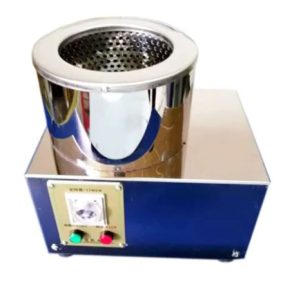

IR Dyeing Machine Dunlin

$0.00

IR Dyeing Machine Dunlin

IR Dyeing machine Dunlin is Safe, high efficiency, environment friendly, energy saving, optimum for new dyeing small sample machines

24 pot 300 ml

Application

This machine is oil bath type infrared laboratory dyeing machine, it combine the advantages of traditional glycerol dyeing machine with common infrared dyeing machine together. It’s apply to dyeing and testing the color fastness of the knitted

fabric, woven fabric, yarn, cotton, loose fiber, zipper etc. It was special design for dyeing industry, chemical industry, raw material, cloth which can simulate the production conditions exactly and reach the process effect. Used for simulate the dyeing process in actual production, even apply for the small-batch production.

Characteristics

Safety, high efficiency, environmental protection, energy saving and consumption reduction, which can fully meet the requirements of dyeing and color matching experiments; segmented heating sampling experiments, segmented, uniform

dyeing and Permeability test, dye absorption rate tests of pH, temperature and bath ratio differences, concentration and other tests, etc. In addition, the machine is highly personalized, and can make different specifications of dyeing steel

cups according to customer needs.

Feature

Easy to operate, dye pot can be individually Turn plate removed to save waiting time. The ability to conduct the tests of various dyes and chemicals on dispersing, leveling, liquor ratio exhausting etc. l Special recommendation for “STEP DYEING “to select the best dyestuff and combinations for the most

Suitable dyeing curve to achieve the highest efficiency and quality Different sizes of dye pots for various weight of samples with yarn or fabric holders to ensure the good leveling result .There will be no crease mark. Suitable for low liquor ratio dyeing. Sample weight from 4g to 20g.

Special design for humanity, durability and easy-maintenance. Safe, high efficiency, environment friendly, energy saving, optimum for new dyeing small sample machines Product Parameter of IR Dyeing machine Dunlin

specifically designed with a focus on human usability, durability, and ease of maintenance. It prioritizes safety, high efficiency, and environmental friendliness while also being energy-saving. This machine is optimal for new dyeing small sample machines due to its product parameter advantages.

specifically designed to prioritize humanity, durability, and ease of maintenance. It offers a safe, high-efficiency operation while being environmentally friendly and energy-saving. This machine is optimal for new dyeing small sample machines due to its specialized features and product parameters.

Model : IF-24S

Infrared Laboratory Dyeing Machine

Key Specification

Model : IF-12S

IF-24S Staining cup number

12/24 Staining cup volume

300cc OR 425cc Control mode

LCD Microprocessor type,

programmable process number: 100(0—99),

100 programmable steps per process Heat method

Infrared heat Temperature range

RT – 140 ℃ Temperature control accuracy

±0.2 ℃ Heating rate

0 – 3.5 ℃ / min Cooling rate

0.2 – 5 ℃ / min Cooling method

Air-cooled Rotation speed

0 – 60 rpm Liquor ratio

1:5 -1:100 Power supply

1∮AC 220V 50/60HZ Dimensions( L x W x H)

670×670×780mm

860×680×780mm Weight

100kg

120kg

Standard Accessories

Cups 1set

Put the test sample. Cups stand 1set

Place where to put cups. Protective glove 1set

To avoid to be hurt by HT cups.

Model: IF-24SCapacity: 24 pots

Brad: DUNLIN

Origin: China

Color dyeing tests for various dyestuffs of IR Dyeing machine Dunlin

- Step dyeing tests. C. Dispersing, levelling and impregnating test. D. High or low liquor ratio exhausting tests. E. Fabric steak and staining tests. F. Concentration tests and others. Protection and Safety gates to protect. Temperature control accuracy +/- 0.2degree

Working temperature of IR Dyeing machine Dunlin 20 – 140 degree Heating rate of dye bath 0 – 3.5degree / min Cooling rate 0.2 – 5 degree / min Cooling method air-cooled / Auto Speed control frequency conversion Rotation speed 0 – 60 turn / min Microprocessor type Newhaven controller 99 programs each Program with 99steps.

IR Dyeing machine

Related products

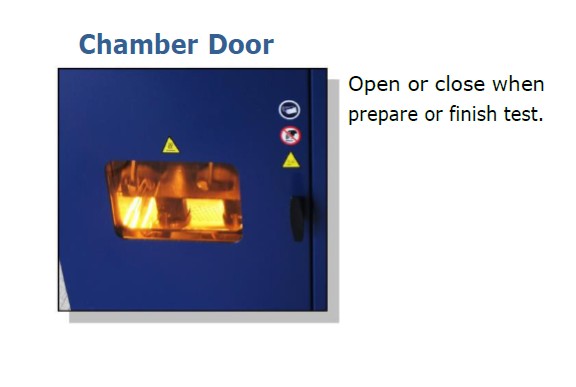

Bursting strength tester

Bursting strength tester

true burst

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

- Bursting pressure can reach up to 1.2MPa 5. The maximum burst and expansion degree can reach 70mm. 6. Strengthen the lighting system on the test surface. 7. The main aerodynamic force helps to clamp the sample system. 8. A variety of test areas are available, and the switching is easy.

- A variety of unit conversions between Chinese and English. 10. Reliable anti-pinch safety protection design. [Technical parameter]: 1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized) 2. The minimum graduation value: 0.0001Mpa 3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree pressurization.

HTHP Glycerin bath dyeing machine

HTHP Glycerin Bath Dyeing Machine

HTHP dyeing machine

- High Temperature Capability - Operates up to 140°C or more, ideal for disperse dyeing of polyester which requires elevated temperatures.

- Glycerin as Heat Transfer Medium - Glycerin allows for precise and uniform heating beyond the boiling point of water, without pressure buildup as in steam-based systems.

- Small Sample Dyeing - Used for lab-scale dyeing of fabric or yarn samples (commonly 5–10 g per tube), useful in R&D or color matching.

- Multiple Sample Capacity - Usually has multiple dyeing tubes/chambers for simultaneous dyeing of several samples under identical conditions.

- Accurate Temperature and Time Control - Digital or microprocessor-based controllers regulate temperature, heating rate, and timing precisely.

- Uniform Dyeing - Ensures even dye penetration due to consistent heat distribution and controlled rotation or agitation.

- Energy Efficient Glycerin’s heat retention reduces energy consumption compared to steam systems.

- Compact and Durable Design - Bench-top design, made from stainless steel and heat-resistant components for long life and lab use.

- Uniform Heating with Glycerin - Glycerin provides consistent heat transfer, ensuring even dye uptake and minimizing shade variation.

- Energy Efficient- Glycerin retains heat longer, reducing energy consumption compared to traditional steam-based dyeing.

- Accurate Process Control - Precise temperature and time control enhance reproducibility and dyeing consistency.

- Ideal for Lab and Sample Work - Perfect for R&D, shade matching, and recipe development with small fabric or yarn samples.

- Multi-Sample Dyeing - Allows multiple samples to be dyed simultaneously under identical conditions, saving time and effort.

- Compact and Safe - Bench-top design fits in laboratories and is safer than high-pressure steam systems.

- Low Maintenance - Simplified operation and fewer mechanical parts compared to steam-based systems lower upkeep needs.

- Faster Dyeing Cycles- Glycerin heats and cools quickly, reducing overall dyeing time.

- High-Temperature Operation - Capable of dyeing up to 140–150°C, suitable for synthetic fibers like polyester.

- Glycerin as Heat Medium - Uses glycerin for uniform, efficient heat transfer without generating high steam pressure.

- Multiple Dyeing Chambers - Usually equipped with 6–24 tubes for simultaneous multi-sample dyeing under identical conditions.

- Digital Temperature Controller- Offers precise control of temperature, time, and heating rate with programmable settings.

- Compact and Lab-Friendly Design - Bench-top model, easy to operate in laboratory environments with limited space.

- Stainless Steel Construction - Corrosion-resistant and durable for long-term, high-temperature operation.

- Safety Features - Includes over-temperature protection and thermal insulation to prevent heat loss and ensure operator safety.

- Agitation or Sample Rotation- Some models offer rotation or agitation for uniform dye penetration.

- Energy Efficient Heating - Glycerin’s heat retention improves energy efficiency over water- or steam-based systems.

- Low Maintenance - Simplified mechanical system reduces the need for frequent servicing.

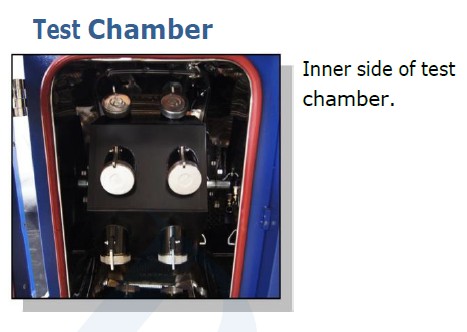

Perspiration Tester

Perspiration Tester

Perspiration Tester

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Stainless Steel Frame - Corrosion-resistant body for durability and long-term use.

- Multi-Sample Capacity - Can hold up to 20 or more specimens for batch testing.

- Standardized Loading Weight- Applies uniform pressure (usually 12.5 kPa) across all samples.

- Removable Plates - Glass or acrylic plates ensure even contact and easy cleaning.

- Compact Design- Space-saving, bench-top model ideal for lab environments.

- Complies with Test Standards - Meets ISO 105 E04, AATCC 15, and related perspiration fastness standards.

- Ease of Operation - Simple loading, unloading, and incubation process.

- High-Temperature Resistance - Can be used inside incubators at 37°C or ovens as required.

- Prepare the Test Solution - Mix artificial acidic or alkaline perspiration as per standard (ISO or AATCC).

- Cut the Fabric Samples - Cut both the test fabric and adjacent white fabric (usually cotton) to standard size.

- Soak the Samples - Immerse the fabric sandwich (test + adjacent) in the test solution for 30 minutes.

- Remove Excess Liquid - Gently squeeze or blot to remove extra moisture—do not dry.

- Load in the Tester- Place each sandwich between glass or acrylic separator plates in the tester.

- Apply Pressure - Tighten the top plate or place the standard weight on top to apply uniform pressure.

- Incubate - Keep the loaded tester in an oven or incubator at 37°C for 4–16 hours (depending on the method).

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Dry and Evaluate - Remove, air dry the samples, then assess color change and staining using a gray scale.

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

Perspiration Tester

Steam Soaping machine

Steam Soaping Machine

A Steam Soaping Machine is a specialized laboratory apparatus used in textile dyeing processes, particularly for post-dyeing treatments like soaping, which enhances color fastness and removes unfixed dyes from fabric samples. This machine is designed to perform soaping treatments on dyed textile samples using steam. Soaping is a critical step in dyeing, especially for reactive dyes, as it removes unfixed dye particles, ensuring better color fastness and preventing dye bleeding. The steam soaping process involves treating the dyed fabric with a soaping solution at elevated temperatures, facilitated by steam, to achieve optimal results. ⚙️ Key Features of Steam Soaping Machine - Beaker Material: Constructed with high-grade 316L stainless steel for excellent corrosion resistance and durability.- Operation Modes: Offers both automatic control and manual water filling options, providing flexibility in operation. - Drainage System: Equipped with an automatic drainage device for efficient removal of used solutions.- Temperature Control: Precise temperature regulation to maintain optimal soaping conditions.- Compact Design: Suitable for laboratory settings, occupying minimal space while delivering effective performance. ✅ Benefits of Steam Soaping Machine - Enhanced Color Fastness: Effectively removes unfixed dyes, resulting in improved wash and rub fastness of the fabric.- Efficient Processing: Reduces the time required for post-dyeing treatments compared to conventional methods.- Consistent Results: Provides uniform treatment across samples, ensuring reproducibility in testing and quality control.- Resource Optimization: Minimizes water and chemical usage through controlled processing parameters.- Versatility: Applicable to various fabric types and dye classes, making it a valuable tool in research and development. Typical Applications - Laboratory Testing: Used in dyeing laboratories for evaluating the fastness properties of dyed samples. - Research and Development: Assists in developing and optimizing dyeing processes and formulations. - Quality Control: Ensures that dyed fabrics meet specified fastness standards before bulk production. In summary, a Steam Soaping Machine is an essential laboratory instrument in the textile industry, facilitating efficient and effective post-dyeing treatments to enhance the quality and durability of dyed fabrics. Features of Steam Soaping Machine:- High-Grade Stainless Steel Beakers - Made from 316L stainless steel for excellent chemical and heat resistance.

- Steam-Based Heating - Uses direct or indirect steam to maintain consistent high temperatures ideal for soaping.

- Precise Temperature Control - Maintains stable temperatures (typically up to 98–100°C) for effective removal of unfixed dyes.

- Automatic and Manual Modes - Offers both programmable automatic cycles and manual operation for flexibility.

- Beaker Agitation or Rotation - Ensures uniform soaping action across fabric surfaces.

- Automatic Drainage System - Efficiently removes used soaping solution to speed up cycle changeovers.

- Compact Design - Fits well in lab settings while allowing multiple samples to be processed simultaneously.

- Safety Features - Includes pressure and temperature protection systems to ensure safe operation.

- Low Water and Chemical Use - Designed for minimal liquor ratios, enhancing sustainability.

- User-Friendly Interface - Simple digital controls or touch panel for easy operation and cycle programming.

- Prepare the Dyed Sample - After dyeing, rinse the fabric to remove surface dye and prepare it for soaping.

- Load the Fabric - Place the dyed fabric or sample into the beakers or holders inside the machine.

- Add Soaping Solution - Pour the prepared soaping agent (usually a detergent solution) into the beakers or tank as per recipe.

- Set Parameters

- Start the Cycle - Begin the soaping process. The machine will heat the solution using steam and agitate/rotate the beakers for even treatment.

- Drain and Rinse - After the cycle ends, the machine may auto-drain. Rinse the fabric with warm water to remove residual chemicals.

- Unload the Samples - Carefully remove the fabric. Inspect for evenness and color fastness improvement.

- Clean the Machine - Rinse and dry the beakers or tank to maintain hygiene for the next use.

used for sample soaping after dyeing in laboratory

Beaker material: 316L S/S

automatic control / manual filling water device, with automatic drainage device.

Steam Soaping machine Dunlin price in Bangladesh

Steam Soaping machine Dunlin in textile testing equipment

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Steam Soaping machine Dunlin price in Bangladesh

used for sample soaping after dyeing in laboratory

Beaker material: 316L S/S

automatic control / manual filling water device, with automatic drainage device.

Steam Soaping machine Dunlin price in Bangladesh

Steam Soaping machine Dunlin in textile testing equipment

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Steam Soaping machine Dunlin price in Bangladesh Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

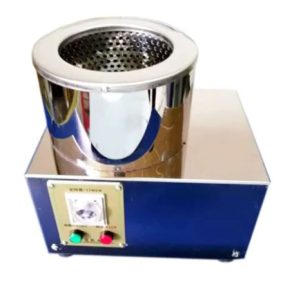

Laboratory hydro Extractor

Laboratory Hydro Extractor

A Laboratory Hydro Extractor is a compact, high-speed centrifuge used in textile labs to remove excess water from fabric or yarn samples after dyeing or washing. It works on the principle of centrifugal force, efficiently reducing moisture content before drying. Key Features:- Centrifugal Water Extraction - Uses high-speed spinning (typically 1400–2800 RPM) to extract water from textiles.

- Stainless Steel Inner Basket - Perforated drum holds fabric/yarn securely and allows water to drain efficiently.

- Compact Lab Design - Space-saving unit designed specifically for laboratory sample sizes.

- Digital Timer and Speed Control - Allows precise setting of spin duration and RPM to match sample needs.

- Safety Lock System - Ensures the lid remains closed during operation for user safety.

- Quick Water Removal - Significantly reduces drying time by extracting up to 90–95% of water content.

- Low Noise and Vibration - Balanced design ensures quiet and stable operation.

- Efficient Water Removal - Rapidly extracts 90–95% of water from samples, reducing drying time significantly.

- Saves Time and Energy - Cuts down the load on dryers and shortens total processing time in lab workflows.

- Improves Sample Quality - Gentle spinning preserves fabric structure, avoiding damage or distortion.

- Precise Control - Adjustable speed and timer ensure optimal settings for different fabric types.

- Compact and Lab-Friendly - Small footprint ideal for laboratory use with limited space.

- User Safety - Safety lock prevents lid opening during operation, protecting the user.

- Cost-Effective - Reduces the need for extended dryer use, saving on electricity and equipment wear.

- Versatile Use - Suitable for yarn, fabric, and garment samples across various fiber types.

- High-Speed Centrifugal Operation - Typically runs at 1400–2800 RPM for quick and efficient water removal.

- Stainless Steel Inner Drum - Corrosion-resistant, perforated basket for durability and efficient water drainage.

- Digital Timer and Speed Control - Allows precise control of spin duration and speed based on sample type.

- Compact and Portable Design - Ideal for lab environments with limited space.

- Safety Lock Mechanism - Prevents the lid from opening while the machine is in operation.

- Shock Absorption System- Reduces vibration and noise for smooth, stable performance.

- Quick Cycle Times - Short dewatering cycles improve lab throughput and efficiency.

- Low Maintenance Design - Simple mechanical setup with easy-to-clean components.

- Sample Versatility - Suitable for small fabric swatches, yarns, and small garments.

- Energy Efficient - Uses minimal power while delivering high performance.

- Prepare the Sample - After dyeing or washing, gently squeeze excess water from the fabric or yarn sample by hand.

- Load the Sample - Open the lid and place the sample evenly in the stainless steel drum. - Avoid overloading or uneven placement to maintain balance.

- Close the Lid securely - Ensure the safety lid is properly closed and locked.

- Set the Timer and Speed - Use the control panel to set the spin time (typically 1–5 minutes) and RPM suitable for the sample type.

- Start the Machine- Press the start button. The extractor will spin at the selected speed to remove water via centrifugal force.

- Wait for Spin Completion - The machine will automatically stop after the timer runs out.

- Unload the Sample - Once the drum stops completely, open the lid and carefully remove the sample.

- Proceed to Drying - The dewatered sample can now be air-dried or placed in a drying oven or stenter.

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Laboratory hydro Extractor Machine Dunlin price in Bangladesh Laboratory hydro Extractor Machine Dunlin in textile Textile testing equipment in Bangladesh Textile testing equipment in Dhaka Textile testing equipment in Uttara MAAM tex Laboratory hydro Extractor Machine Dunlin price in Bangladesh

Laboratory hydro ExtractorController For IR Dyeing Machine

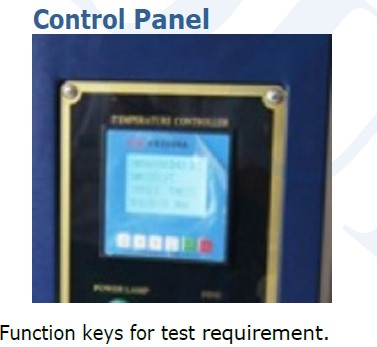

Controller For IR Dyeing Machine

IR Dyeing machine controller

- Temperature Control:- Precisely regulates the infrared heaters to maintain uniform temperature across the dye bath. - Supports customizable heating curves (ramp-up, hold, and cool-down phases).

- Programmable Logic Control (PLC): - Allows operators to set and automate dyeing programs for different fabrics and dye types. - Supports multiple recipes or programs for different batches.

- Real-Time Monitoring and Feedback: - Monitors parameters like temperature, fabric rotation, bath circulation, and timing. - Provides real-time data and alarms for deviations.

- Touchscreen Interface / HMI (Human Machine Interface): - User-friendly interface for configuring and monitoring processes. - Multi-language support and graphical display of process curves.

- Data Logging and Traceability: - Records process data for quality control and traceability.

- Energy Efficiency Optimization: - Manages IR heater output to reduce energy usage. - Often includes features for auto shut-off or idle mode.

- Safety Features: - Includes emergency stop, over-temperature protection, and fault detection systems. 8. Connectivity: - Modern controllers may support Ethernet, Modbus, or other industrial communication protocols for integration into factory automation systems.

- Improved Dyeing Accuracy and Consistency

- Enhanced Energy Efficiency- Infrared heating is more energy-efficient than traditional heating methods.- The controller optimizes energy use by adjusting the IR output based on process needs, reducing overall energy consumption.

- Time Savings- Faster heating and cooling cycles due to infrared technology.- Automated processes reduce manual intervention and cycle times. 4. Better Process Control- Programmable dyeing cycles and precise control over each stage (heating, dyeing, rinsing, cooling).- Real-time monitoring and adjustments improve reliability.

- Reduced Water and Chemical Usage- More efficient dye penetration and fixation mean less water and fewer chemicals are needed for reprocessing or corrections.6. Lower Operational Costs

- Enhanced Safety Built-in alarms, emergency shut-off and automatic fault detection enhance operational safety.8. Data Logging and Traceability- Ability to record and review dyeing process data helps in quality control and troubleshooting.- Facilitates compliance with industry standards and audits.

- User-Friendly Operation- Modern touchscreen interfaces make it easier for operators to manage and monitor processes.- Multilingual support and visual feedback enhance usability.

Pantone book

Pantone Book

Pantone Book

- Formula Guide (Solid Coated & Uncoated) – For spot color printing.

- Color Bridge – Shows Pantone spot colors alongside CMYK equivalents.

- Pantone Fashion, Home + Interiors (FHI) – For textiles, soft goods, and home decor.

- Pantone CMYK and Pastels & Neons Guides – For process printing and special effect colors.

- Formula Guide (Solid Coated & Uncoated)

- Color Bridge Guide (Coated & Uncoated)

- CMYK Guide (Coated & Uncoated)

- Pastels & Neons Guide

- Metallics Guide

- FHI Color Guide (TPG – Paper)

- FHI Cotton Passport & Cotton Planner (TCX – Textile)

- FHI Polyester Swatch Book

- Pantone SkinTone Guide

- Pantone Plastic Standard Chips

Pantone Book

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated