Oscillation type water bath Dyeing Machine

$0.00

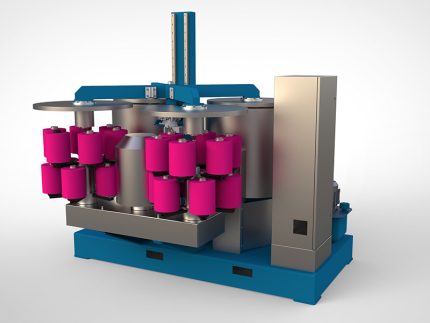

Oscillation Type Water Bath Dyeing Machine

An Oscillation Type Water Bath Dyeing Machine is a laboratory apparatus designed for dyeing and washing textile samples under controlled temperature conditions. It combines a heated water bath with an oscillating mechanism to ensure uniform dye penetration and consistent coloration across fabric or yarn samples.

Key Features of Oscillation Type Water Bath Dyeing Machine

– Oscillating Mechanism: Provides back-and-forth movement to agitate the dye solution, ensuring even contact between the dye and the textile sample.- Multiple Beaker Capacity: Typically accommodates 12 to 24 beakers, allowing simultaneous processing of multiple samples under identical or varied conditions.

– Digital Temperature Control: Maintains precise temperature settings, usually up to 99°C, suitable for various dyeing processes including atmospheric dyeing, scouring, and bleaching.- Adjustable Oscillation Speed: Offers variable speed settings, commonly ranging from 50 to 200 cycles per minute, to accommodate different fabric types and dyeing requirements.

– Programmable Settings: Advanced models come with programmable controllers, allowing users to set and save multiple dyeing protocols for repeatability and efficiency.

Durable Construction: Constructed with high-quality stainless steel (e.g., SUS304), ensuring resistance to corrosion and longevity even under rigorous laboratory conditions.

✅ Benefits of Oscillation Type Water Bath Dyeing Machine

– Uniform Dyeing Results: The oscillation mechanism ensures consistent dye penetration, reducing the risk of uneven coloration and enhancing the reproducibility of results.- Efficiency in Sample Processing: The ability to process multiple samples simultaneously accelerates laboratory workflows and facilitates comparative studies.

– Versatility: Suitable for a range of applications including dyeing, washing, scouring, bleaching, and fastness testing across various textile materials.- Energy and Resource Conservation: Designed for low liquor ratios (e.g., 1:5 to 1:20), these machines minimize water and chemical usage, promoting sustainable laboratory practices.

– Enhanced Safety and Cleanliness: Enclosed beaker systems reduce the risk of spills and exposure to chemicals, ensuring a safer laboratory environment.

Typical Applications of Oscillation Type Water Bath Dyeing Machine

– Textile Research and Development: Ideal for developing and testing new dye formulations and processes on a small scale before scaling up to production levels.

Quality Control: Used in quality assurance laboratories to assess color fastness, dye uptake, and other critical parameters of textile products.- Educational Purposes: Serves as a practical tool in academic settings for teaching dyeing principles and techniques.

In summary, the Oscillation Type Water Bath Dyeing Machine is an essential tool in textile laboratories, offering precise control over dyeing parameters, improving efficiency, and ensuring high-quality, reproducible results across various textile materials.

Features of Oscillation Type Water Bath Dyeing Machine:

- Oscillating Mechanism – Provides back-and-forth movement of beakers for uniform dye penetration and sample agitation.

- Multiple Beaker Capacity – Supports dyeing of 12–24 samples simultaneously, ideal for comparative lab testing.

- Digital Temperature Control – Maintains precise water bath temperature (typically up to 99°C), essential for consistent dyeing.

- Variable Oscillation Speed – Adjustable speed settings (e.g., 50–200 cycles/min) to suit different materials and processes.

- Programmable Settings – Allows setting of temperature, time, and speed for repeatable and automated dyeing cycles.

- Stainless Steel Construction – Corrosion-resistant frame and bath for durability in chemical environments.

- Beaker Safety Holders – Secure placement of beakers to prevent spills and maintain consistent treatment.

- Compact Design – Lab-friendly size for easy integration into research and quality control spaces.

- Low Liquor Ratio Operation – Efficient dyeing using minimal dye bath volume (e.g., 1:5 to 1:20), reducing chemical and water use.

- Quiet and Stable Performance

Engineered for smooth, vibration-free operation in laboratory conditions.

Oscillation Type Dyeing Machine

Brand: DUNLIN

Model:DL-D24

Origin: China

Pot Capacity:24 Pot , 250ml SS Beaker

Heating Mode: Electric heating

Heating Medium: Water/ glycerin

Heating Power: 3 Kw

Temperature Range: RT- 99℃/250℃

Liquor Ratio: 1:5-:20

Thermostat Tiime:0~99min

Oscillation: Speed:50-200rpm

Oscillation Range: 40±3mm

Power supply: 1∮AC 220V 50/60HZ

Dimensions (LxWxH): 880×420×330mm

Oscillation Type Dyeing Machine Dunlin price in Bangladesh

Oscillation Type Dyeing Machine Dunlin in textile

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Oscillation Type Dyeing Machine Dunlin price in Bangladesh

water bath/Shaker bath Dyeing machine

Related products

Digital Yarn Twist Tester

Digital Yarn Twist Tester

Digital Yarn Twist Tester

Digital Yarn Twist Tester

Laboratory tenter

Laboratory Tenter

A Laboratory Tenter (or Lab Stenter) is a small-scale version of an industrial tenter machine used in textile finishing. It is designed for heat-setting, drying, and finishing of fabric samples under controlled conditions in textile testing labs or R&D departments. Key Features:- Heat-Setting and Drying - Simulates the process of setting fabric dimensions and applying finishes using controlled temperature and tension.

- Fabric Width Control - Uses clips or pins on chains or rails to hold fabric edges and stretch them to desired width, just like in full-size tenters.

- Adjustable Temperature and Speed - Digital controls allow precise setting of drying/curing temperature and conveyor speed to match production conditions.

- Compact Design - Bench-top or floor-standing units suitable for labs with limited space.

- Transparent Viewing Chamber - Allows visual inspection of fabric behavior during processing.

- Versatile Application Range - Can process woven, knitted, and nonwoven fabrics of various compositions (cotton, polyester, blends, etc.).

- Accurate Simulation of Production - Replicates industrial finishing processes for reliable lab-scale testing and development.

- Improves Fabric Quality- Allows precise control of heat and tension, optimizing fabric properties like shrinkage, dimensional stability, and hand feel.

- Cost-Effective - Enables process trials and fabric development without using full-scale production equipment.

- Speeds Up R&D - Facilitates quick testing and adjustment of settings for new fabric styles or finishes.

- Versatile Applications - Suitable for drying, heat-setting, finishing, and evaluating different types of fabrics and treatments.

- Space-Efficient - Compact design fits easily into textile labs or sample rooms.

- Energy Efficient- Uses less power than industrial machines, ideal for small-scale and repeated testing.

- Process Control and Reproducibility- Digital controls ensure consistent and repeatable results, aiding in quality assurance and product development.

- Enhances Safety - Built with lab use in mind, featuring insulation and safety systems to protect users.

- Precise Temperature Control - Digital temperature setting (typically up to 220–250°C) for accurate heat-setting and drying.

- Adjustable Fabric Width - Equipped with clip or pin chains to hold and stretch fabric across the width, simulating real stentering.

- Variable Conveyor or Chain Speed- Adjustable speed to control fabric dwell time during processing.

- Compact and Lab-Friendly Design - Designed for bench-top or small floor space use in textile labs.

- Transparent Chamber Window - Allows monitoring of fabric behavior during treatment.

- Digital Display and Control Panel - Easy operation for setting temperature, speed, and time.

- Uniform Heat Distribution- Ensures even treatment across the fabric width for accurate testing.

- Stainless Steel Construction - Durable, corrosion-resistant body for long-term use at high temperatures.

- Safety Features - Includes over-temperature protection, insulated body, and emergency stop functions.

- Sample Versatility - Suitable for various fabric types (woven, knit, synthetic, blends) and lab finishing tasks.

laboratory mini tenter

Steam Soaping machine

Steam Soaping Machine

A Steam Soaping Machine is a specialized laboratory apparatus used in textile dyeing processes, particularly for post-dyeing treatments like soaping, which enhances color fastness and removes unfixed dyes from fabric samples. This machine is designed to perform soaping treatments on dyed textile samples using steam. Soaping is a critical step in dyeing, especially for reactive dyes, as it removes unfixed dye particles, ensuring better color fastness and preventing dye bleeding. The steam soaping process involves treating the dyed fabric with a soaping solution at elevated temperatures, facilitated by steam, to achieve optimal results. ⚙️ Key Features of Steam Soaping Machine - Beaker Material: Constructed with high-grade 316L stainless steel for excellent corrosion resistance and durability.- Operation Modes: Offers both automatic control and manual water filling options, providing flexibility in operation. - Drainage System: Equipped with an automatic drainage device for efficient removal of used solutions.- Temperature Control: Precise temperature regulation to maintain optimal soaping conditions.- Compact Design: Suitable for laboratory settings, occupying minimal space while delivering effective performance. ✅ Benefits of Steam Soaping Machine - Enhanced Color Fastness: Effectively removes unfixed dyes, resulting in improved wash and rub fastness of the fabric.- Efficient Processing: Reduces the time required for post-dyeing treatments compared to conventional methods.- Consistent Results: Provides uniform treatment across samples, ensuring reproducibility in testing and quality control.- Resource Optimization: Minimizes water and chemical usage through controlled processing parameters.- Versatility: Applicable to various fabric types and dye classes, making it a valuable tool in research and development. Typical Applications - Laboratory Testing: Used in dyeing laboratories for evaluating the fastness properties of dyed samples. - Research and Development: Assists in developing and optimizing dyeing processes and formulations. - Quality Control: Ensures that dyed fabrics meet specified fastness standards before bulk production. In summary, a Steam Soaping Machine is an essential laboratory instrument in the textile industry, facilitating efficient and effective post-dyeing treatments to enhance the quality and durability of dyed fabrics. Features of Steam Soaping Machine:- High-Grade Stainless Steel Beakers - Made from 316L stainless steel for excellent chemical and heat resistance.

- Steam-Based Heating - Uses direct or indirect steam to maintain consistent high temperatures ideal for soaping.

- Precise Temperature Control - Maintains stable temperatures (typically up to 98–100°C) for effective removal of unfixed dyes.

- Automatic and Manual Modes - Offers both programmable automatic cycles and manual operation for flexibility.

- Beaker Agitation or Rotation - Ensures uniform soaping action across fabric surfaces.

- Automatic Drainage System - Efficiently removes used soaping solution to speed up cycle changeovers.

- Compact Design - Fits well in lab settings while allowing multiple samples to be processed simultaneously.

- Safety Features - Includes pressure and temperature protection systems to ensure safe operation.

- Low Water and Chemical Use - Designed for minimal liquor ratios, enhancing sustainability.

- User-Friendly Interface - Simple digital controls or touch panel for easy operation and cycle programming.

- Prepare the Dyed Sample - After dyeing, rinse the fabric to remove surface dye and prepare it for soaping.

- Load the Fabric - Place the dyed fabric or sample into the beakers or holders inside the machine.

- Add Soaping Solution - Pour the prepared soaping agent (usually a detergent solution) into the beakers or tank as per recipe.

- Set Parameters

- Start the Cycle - Begin the soaping process. The machine will heat the solution using steam and agitate/rotate the beakers for even treatment.

- Drain and Rinse - After the cycle ends, the machine may auto-drain. Rinse the fabric with warm water to remove residual chemicals.

- Unload the Samples - Carefully remove the fabric. Inspect for evenness and color fastness improvement.

- Clean the Machine - Rinse and dry the beakers or tank to maintain hygiene for the next use.

used for sample soaping after dyeing in laboratory

Beaker material: 316L S/S

automatic control / manual filling water device, with automatic drainage device.

Steam Soaping machine Dunlin price in Bangladesh

Steam Soaping machine Dunlin in textile testing equipment

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Steam Soaping machine Dunlin price in Bangladesh

used for sample soaping after dyeing in laboratory

Beaker material: 316L S/S

automatic control / manual filling water device, with automatic drainage device.

Steam Soaping machine Dunlin price in Bangladesh

Steam Soaping machine Dunlin in textile testing equipment

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Steam Soaping machine Dunlin price in Bangladesh Bursting strength tester

Bursting strength tester

true burst

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

- Bursting pressure can reach up to 1.2MPa 5. The maximum burst and expansion degree can reach 70mm. 6. Strengthen the lighting system on the test surface. 7. The main aerodynamic force helps to clamp the sample system. 8. A variety of test areas are available, and the switching is easy.

- A variety of unit conversions between Chinese and English. 10. Reliable anti-pinch safety protection design. [Technical parameter]: 1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized) 2. The minimum graduation value: 0.0001Mpa 3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree pressurization.

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

Automatic Bobbin Hydro extractor

Automatic Bobbin Hydro extractor

Automatic Bobbin Hydro extractor

- Computer system: Foshan HuaGao Chinese English computer, equipped with LG PLC.

- Electromagnetic valve: Ningbo Jiaerling

- Frequency converter: Use Made in China frequency converters.

- Pump: self-made high head and large flow centrifugal water pump.

- Main pump motor: Anhui Wannan Motor.

- Master cylinder liquid level: Use 4-20mA analog signal output.

- Level of deputy temporary worker: use foam water level gauge. (American Mike)

- Temperature detection and display: digital temperature display instrument, dual temperature measuring probes.

- The safety system has a triple cylinder head safety interlock mechanism, and the main cylinder is equipped with a stainless

- steel safety valve.

- Heat exchanger: external spacer heating.

- Feeding system: Quantitative feeding based on the process curve.

- Circulation system: The main pump flows internally and externally, which is automatically controlled by a computer or manually controlled by a relay.

- Valves: Y valves are used for heating, stainless steel Y valves are used for single inlet and single row, and other Y valves are produced by joint ventures.

- Temperature control: on-off temperature control, controlled by a computer, with automatic heating, cooling, and insulation functions.

- Dyeing method: air cushion type.

- Opening method: manual opening.

- Surface treatment: polishing inside and outside the cylinder.

- Cage: Each dyeing machine is equipped with butterfly blades and self-locking locks.

- Body plate: high-quality stainless steel. (S31603)

- Bath ratio: 1:5-1:6

- Chemical material system: including heating and water adding functions, including overflow type salt melting device.

- Overflow cleaning: The cleaning port is installed on the upper part of the cylinder port, and the bottom of the cylinder is filled with water, while the cylinder is drained for easy cleaning.

- Commutation method: Novel "U" type commutation.

- Random accessories: Each model comes with one set of mechanical seals, pot mouth rings, and reversing seals for the main and auxiliary pumps.

Automatic Bobbin Hydro extractor

Pantone book

Pantone Book

Pantone Book

- Formula Guide (Solid Coated & Uncoated) – For spot color printing.

- Color Bridge – Shows Pantone spot colors alongside CMYK equivalents.

- Pantone Fashion, Home + Interiors (FHI) – For textiles, soft goods, and home decor.

- Pantone CMYK and Pastels & Neons Guides – For process printing and special effect colors.

- Formula Guide (Solid Coated & Uncoated)

- Color Bridge Guide (Coated & Uncoated)

- CMYK Guide (Coated & Uncoated)

- Pastels & Neons Guide

- Metallics Guide

- FHI Color Guide (TPG – Paper)

- FHI Cotton Passport & Cotton Planner (TCX – Textile)

- FHI Polyester Swatch Book

- Pantone SkinTone Guide

- Pantone Plastic Standard Chips

Pantone Book

Fabric flame retardant tester

Fabric Flame Retardant Tester

A Fabric Flame Retardant Tester is a specialized laboratory instrument designed to evaluate the flammability characteristics of textiles. It assesses how fabrics react to direct flame exposure, measuring parameters such as ignition time, flame spread rate, after-flame duration, and afterglow time. This testing is crucial for ensuring that textiles meet safety standards for various applications, including apparel, home furnishings, and industrial uses. Purpose and Applications The primary purpose of a Fabric Flame Retardant Tester is to determine the flame resistance of textile materials. This is essential for:- Apparel Safety: Ensuring garments, especially children's sleepwear and industrial work wear, meet flammability standards. - Home Textiles: Testing curtains, drapes, upholstery, and bedding for fire safety compliance. - Technical Textiles: Evaluating materials used in tents, protective clothing, and automotive interiors. ⚙️ Key Features Modern Fabric Flame Retardant Testers incorporate several features to ensure accurate and reliable testing:- Adjustable Burner Angles: Allowing tests at various orientations (e.g., 0°, 45°, 90°) to simulate different real-world scenarios. Automated Ignition Systems: Providing consistent flame application and reducing operator variability. - Digital Timing Mechanisms: Accurately recording ignition time, flame spread, after-flame, and afterglow durations. - Transparent Observation Windows: Enabling safe monitoring of the test without exposure to hazards. - Compliance with International Standards: Meeting protocols such as ASTM D6413, ISO 6941, and EN ISO 15025 for standardized testing procedures. Testing Standards Fabric Flame Retardant Testers are designed to comply with various international standards, including: - ASTM D6413: Standard Test Method for Flame Resistance of Textiles (Vertical Test). - ISO 6941: Textiles — burning behavior — Measurement of flame spread properties of vertically oriented specimens. - EN ISO 15025: Protective clothing — Protection against heat and flame — Method of test for limited flame spread. ️ How It Works- Sample Preparation: A fabric specimen is cut to specified dimensions and conditioned as per standard requirements.

- Mounting: The sample is mounted vertically or at a specified angle in the testing chamber.

- Ignition: A controlled flame is applied to the fabric for a predetermined time.

- Observation: The tester records ignition time, flame spread, after-flame time, and afterglow time.

- Evaluation: Results are compared against standard criteria to determine compliance.

- Prepare the Sample

- Mount the Sample

- Set Up the Burner Position the burner at the required angle (usually 90° for vertical tests).

- Ignite the Flame - Apply the flame to the bottom edge of the fabric for 12 seconds.

- Observe and Measure - Start timing when flame is applied.

- Record the Results

- Compare with Standards

burning of flammable textile materials after ignition.

(specific ignition nozzles and sample holders can be customized to meet multiple criteria).

Related standards

GB/T14644 ASTM D1230 CFR1610 etc.

Technical parameters

1. The spread of time:0 ~ 999.9S resolution 0.1S

2. The temperature inside the box shows:Room temperature -99 degrees C resolution 1 c

3. Igniting time:1S

4. Type of igniter:4 1/2 syringe

5. Sample clip size:Outer frame:204mm * 78mm inner frame:152mm×38mm

6. Distance from the top of the igniter to the sample surface:8mm

7. Studio size and outline size

Studio size:370mm×220mm×350mm

Outline size:375mm×245mm×478mm

8. Power supply:AC220V 50Hz 20W

9. Weight:18Kg

burning of flammable textile materials after ignition.

(specific ignition nozzles and sample holders can be customized to meet multiple criteria).

Related standards

GB/T14644 ASTM D1230 CFR1610 etc.

Technical parameters

1. The spread of time:0 ~ 999.9S resolution 0.1S

2. The temperature inside the box shows:Room temperature -99 degrees C resolution 1 c

3. Igniting time:1S

4. Type of igniter:4 1/2 syringe

5. Sample clip size:Outer frame:204mm * 78mm inner frame:152mm×38mm

6. Distance from the top of the igniter to the sample surface:8mm

7. Studio size and outline size

Studio size:370mm×220mm×350mm

Outline size:375mm×245mm×478mm

8. Power supply:AC220V 50Hz 20W

9. Weight:18Kg

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated