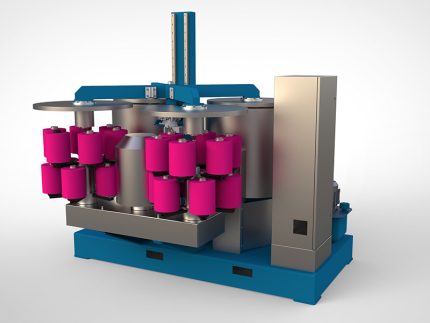

Sample Cone Yarn Dyeing machine

$0.00

Sample Cone Yarn Dyeing Machine

Sample Cone Yarn Dyeing Machine

A Sample Cone Yarn Dyeing Machine is a lab-scale dyeing unit designed for dyeing small batches of yarn wound on cones. It simulates the bulk cone dyeing process, allowing testing of dye formulations, shade matching, and process development before large-scale production.

Purpose Sample Cone Yarn Dyeing Machine:

To dye yarn cones under controlled conditions using a small quantity of dyes, water, and chemicals.

Working Principle Sample Cone Yarn Dyeing Machine:

Yarn cones are mounted on dyeing spindles.

The dye liquor is circulated through the yarn from inside (inward flow) or outside (outward flow), ensuring uniform penetration.

Temperature, pressure, and time are controlled digitally.

Applications of Sample Cone Yarn Dyeing Machine:

Lab trials in dye houses

R&D in dye and chemical manufacturing

Shade and recipe matching

Process optimization before bulk production

Benefits of Sample Cone Yarn Dyeing Machine:

Cost-Effective Testing – Uses minimal dye, water, and energy for trial batches.

Accurate Shade Development – Matches production dyeing conditions for reliable color matching.

Quick Recipe Validation – Fast testing of dyeing recipes before bulk production.

Time Saving – Rapid cycle time helps speed up R&D and approvals.

Versatile Applications – Suitable for different yarn types: cotton, polyester, blends, etc.

Improved Quality Control – Identifies dyeing issues early in lab conditions.

Features of Sample Cone Yarn Dyeing Machine:

Compact Design – Lab-friendly, space-saving build.

Digital Controller – Precise control of temperature, time, and pressure.

Reversible Flow System – Ensures uniform dyeing by alternating liquor flow.

Stainless Steel Construction – Durable and corrosion-resistant.

Pressure & Temperature Safety Devices – For safe high-temperature operations.

Easy Loading & Unloading – Designed for quick cone placement and removal.

How to Use Sample Cone Yarn Dyeing Machine:

Prepare the Yarn – Wind yarn uniformly onto dye able cones (perforated cones preferred).

Load the Machine – Mount the cones on dyeing spindles and secure the lid properly.

Add Dye Liquor – Fill the tank with water, dye, auxiliaries, and chemicals based on the recipe.

Set Parameters – Use the digital controller to set: – Dyeing temperature – Holding time – Heating rate – Flow direction (inward/outward)

Start Dyeing Cycle – Begin the process; the machine will heat and circulate dye liquor.

Monitor the Process – Watch for pressure, temperature, and flow direction changes if applicable.

Cool Down & Drain – After dyeing, allow the machine to cool. Drain the bath and rinse the yarn.

Unload and Dry – Remove the cones carefully and dry them using a hydro extractor or dryer.

Safety Tips for Sample Cone Yarn Dyeing Machine:

Use Heat-Resistant Gloves – Always wear gloves when handling hot parts or dye liquor.

Secure the Lid properly – Ensure the lid is tightly closed before starting to avoid leaks under pressure.

Avoid Overloading – Do not exceed the recommended cone or liquor load to prevent uneven dyeing or damage.

Stay Clear During Operation – Keep hands and tools away from moving or hot parts while in use.

Ventilation – Operate in a well-ventilated area to avoid inhaling steam or fumes.

Emergency Stop – Know the location and function of the emergency stop button.

Basic Maintenance Checklist:

Daily:

[ ] Clean machine interior and remove dye residue

[ ] Check for any leaks or unusual noises

[ ] Rinse pump and pipes with clean water

Weekly:

[ ] Inspect gaskets and lid seals for wear

[ ] Check electrical connections and display panel

[ ] Clean and lubricate valve mechanisms

Monthly:

[ ] Test temperature and pressure sensors

[ ] Inspect flow direction system for proper switching

[ ] Calibrate temperature control if needed

Sample Cone Yarn Dyeing Machine – Maintenance & Safety Checklist

Daily Maintenance:

☐ Clean dyeing vessel and spindles

☐ Rinse piping and pump with clean water

☐ Check for leaks, noises, or unusual vibrations

Weekly Maintenance:

☐ Inspect lid gasket and seals

☐ Clean valves and filter (if present)

☐ Check control panel buttons and display

☐ Tighten any loose screws or fittings

Monthly Maintenance:

☐ Test and calibrate temperature & pressure sensors

☐ Inspect and clean reversible flow system

☐ Check motor and pump for overheating or wear

Safety Checklist:

☐ Wear heat-resistant gloves & protective eyewear

☐ Secure lid tightly before starting

☐ Do not exceed load capacity

☐ Keep area ventilated during operation

☐ Know emergency stop location

☐ Let machine cool before cleaning or unloading

TECHNICAL DATA OF THE MACHINE

- Computer system: Foshan HuaGao Chinese English computer, equipped with LG PLC.

- Electromagnetic valve: Ningbo Jiaerling

- Frequency converter: Use Made in China frequency converters.

- Pump: self-made high head and large flow centrifugal water pump.

- Main pump motor: Anhui Wannan Motor.

- Master cylinder liquid level: Use 4-20mA analog signal output.

- Level of deputy temporary worker: use foam water level gauge. (American Mike)

- Temperature detection and display: digital temperature display instrument, dual temperature measuring probes.

- The safety system has a triple cylinder head safety interlock mechanism, and the main cylinder is equipped with a stainless

- steel safety valve.

- Heat exchanger: external spacer heating.

- Feeding system: Quantitative feeding based on the process curve.

- Circulation system: The main pump flows internally and externally, which is automatically controlled by a computer or manually controlled by a relay.

- Valves: Y valves are used for heating, stainless steel Y valves are used for single inlet and single row, and other Y valves are produced by joint ventures.

- Temperature control: on-off temperature control, controlled by a computer, with automatic heating, cooling, and insulation functions.

- Dyeing method: air cushion type.

- Opening method: manual opening.

- Surface treatment: polishing inside and outside the cylinder.

- Cage: Each dyeing machine is equipped with butterfly blades and self-locking locks.

- Body plate: high-quality stainless steel. (S31603)

- Bath ratio: 1:5-1:6

- Chemical material system: including heating and water adding functions, including overflow type salt melting device.

- Overflow cleaning: The cleaning port is installed on the upper part of the cylinder port, and the bottom of the cylinder is filled with water, while the cylinder is drained for easy cleaning.

- Commutation method: Novel “U” type commutation.

- Random accessories: Each model comes with one set of mechanical seals, pot mouth rings, and reversing seals for the main and auxiliary pumps.

Sample Cone Yarn Dyeing Machine

Related products

Automatic Bobbin Hydro extractor

Automatic Bobbin Hydro extractor

Automatic Bobbin Hydro extractor

- Computer system: Foshan HuaGao Chinese English computer, equipped with LG PLC.

- Electromagnetic valve: Ningbo Jiaerling

- Frequency converter: Use Made in China frequency converters.

- Pump: self-made high head and large flow centrifugal water pump.

- Main pump motor: Anhui Wannan Motor.

- Master cylinder liquid level: Use 4-20mA analog signal output.

- Level of deputy temporary worker: use foam water level gauge. (American Mike)

- Temperature detection and display: digital temperature display instrument, dual temperature measuring probes.

- The safety system has a triple cylinder head safety interlock mechanism, and the main cylinder is equipped with a stainless

- steel safety valve.

- Heat exchanger: external spacer heating.

- Feeding system: Quantitative feeding based on the process curve.

- Circulation system: The main pump flows internally and externally, which is automatically controlled by a computer or manually controlled by a relay.

- Valves: Y valves are used for heating, stainless steel Y valves are used for single inlet and single row, and other Y valves are produced by joint ventures.

- Temperature control: on-off temperature control, controlled by a computer, with automatic heating, cooling, and insulation functions.

- Dyeing method: air cushion type.

- Opening method: manual opening.

- Surface treatment: polishing inside and outside the cylinder.

- Cage: Each dyeing machine is equipped with butterfly blades and self-locking locks.

- Body plate: high-quality stainless steel. (S31603)

- Bath ratio: 1:5-1:6

- Chemical material system: including heating and water adding functions, including overflow type salt melting device.

- Overflow cleaning: The cleaning port is installed on the upper part of the cylinder port, and the bottom of the cylinder is filled with water, while the cylinder is drained for easy cleaning.

- Commutation method: Novel "U" type commutation.

- Random accessories: Each model comes with one set of mechanical seals, pot mouth rings, and reversing seals for the main and auxiliary pumps.

Automatic Bobbin Hydro extractor

Cone yarn Dyeing machine

Cone Yarn Dyeing Machine

Cone Yarn Dyeing Machine

- Computer system: Foshan HuaGao Chinese English computer, equipped with LG PLC.

- Electromagnetic valve: Ningbo Jiaerling

- Frequency converter: Use Made in China frequency converters.

- Pump: self-made high head and large flow centrifugal water pump.

- Main pump motor: Anhui Wannan Motor.

- Master cylinder liquid level: Use 4-20mA analog signal output.

- Level of deputy temporary worker: use foam water level gauge. (American Mike)

- Temperature detection and display: digital temperature display instrument, dual temperature measuring probes.

- The safety system has a triple cylinder head safety interlock mechanism, and the main cylinder is equipped with a stainless

- steel safety valve.

- Heat exchanger: external spacer heating.

- Feeding system: Quantitative feeding based on the process curve.

- Circulation system: The main pump flows internally and externally, which is automatically controlled by a computer or manually controlled by a relay.

- Valves: Y valves are used for heating, stainless steel Y valves are used for single inlet and single row, and other Y valves are produced by joint ventures.

- Temperature control: on-off temperature control, controlled by a computer, with automatic heating, cooling, and insulation functions.

- Dyeing method: air cushion type.

- Opening method: manual opening.

- Surface treatment: polishing inside and outside the cylinder.

- Cage: Each dyeing machine is equipped with butterfly blades and self-locking locks.

- Body plate: high-quality stainless steel. (S31603)

- Bath ratio: 1:5-1:6

- Chemical material system: including heating and water adding functions, including overflow type salt melting device.

- Overflow cleaning: The cleaning port is installed on the upper part of the cylinder port, and the bottom of the cylinder is filled with water, while the cylinder is drained for easy cleaning.

- Commutation method: Novel "U" type commutation.

- Random accessories: Each model comes with one set of mechanical seals, pot mouth rings, and reversing seals for the main and auxiliary pumps.

High speed hard winding machine

High Speed Hard Winding Machine

High Speed Hard Winding Machine

- Increased Productivity - High-speed operation reduces winding time significantly.

- Consistent Package Quality - Ensures uniform and firm yarn packages ideal for further processing.

- Reduced Yarn Breakage - Precise tension control minimizes yarn damage during winding.

- Versatility - Handles different types of yarns including delicate and coarse fibers.

- User-Friendly Operation - Simple controls and automation reduce operator fatigue.

- Improved Efficiency - Automatic package build-up reduces manual adjustments.

- Space Saving - Compact design fits well in production lines and labs.

- Set Up the Machine - Switch on the power and check all safety guards.

- Load Yarn - Thread the yarn through tension guides and eyelets as per the manual.

- Adjust Tension - Set tension according to yarn type to avoid slack or breakage.

- Place Empty Cone/Package - Mount the empty cone or package holder securely.

- Start Winding- Press the start button; machine will begin winding at set speed.

- Monitor the Process - Observe yarn package build-up and make adjustments if necessary.

- Stop and Remove Package - Once winding is complete, stop the machine and remove the yarn package carefully.

- Maintenance - Clean the machine regularly and lubricate moving parts as needed.

- High-Speed Operation - Capable of winding yarns at fast speeds (up to 3000 RPM) to boost productivity.

- Precise Tension Control - Adjustable tension mechanism to prevent yarn breakage and ensure tight winding.

- Automatic Package Formation - Uniform, firm package build-up for consistent yarn quality.

- Versatile Yarn Compatibility - Suitable for cotton, polyester, wool, and blended yarns.

- User-Friendly Interface - Easy controls with digital or analog panels for speed and tension adjustment.

- Robust Construction - Durable stainless steel or metal frame for long-term reliability.

- Safety Features - Includes emergency stop buttons and yarn break sensors.

- Compact Design - Space-saving structure ideal for labs and production floors.

- Low Maintenance - Designed for easy cleaning and minimal upkeep.

High Speed Hard Winding Machine

Oscillation type water bath Dyeing Machine

Oscillation Type Water Bath Dyeing Machine

An Oscillation Type Water Bath Dyeing Machine is a laboratory apparatus designed for dyeing and washing textile samples under controlled temperature conditions. It combines a heated water bath with an oscillating mechanism to ensure uniform dye penetration and consistent coloration across fabric or yarn samples. Key Features of Oscillation Type Water Bath Dyeing Machine - Oscillating Mechanism: Provides back-and-forth movement to agitate the dye solution, ensuring even contact between the dye and the textile sample.- Multiple Beaker Capacity: Typically accommodates 12 to 24 beakers, allowing simultaneous processing of multiple samples under identical or varied conditions. - Digital Temperature Control: Maintains precise temperature settings, usually up to 99°C, suitable for various dyeing processes including atmospheric dyeing, scouring, and bleaching.- Adjustable Oscillation Speed: Offers variable speed settings, commonly ranging from 50 to 200 cycles per minute, to accommodate different fabric types and dyeing requirements. - Programmable Settings: Advanced models come with programmable controllers, allowing users to set and save multiple dyeing protocols for repeatability and efficiency. Durable Construction: Constructed with high-quality stainless steel (e.g., SUS304), ensuring resistance to corrosion and longevity even under rigorous laboratory conditions. ✅ Benefits of Oscillation Type Water Bath Dyeing Machine - Uniform Dyeing Results: The oscillation mechanism ensures consistent dye penetration, reducing the risk of uneven coloration and enhancing the reproducibility of results.- Efficiency in Sample Processing: The ability to process multiple samples simultaneously accelerates laboratory workflows and facilitates comparative studies. - Versatility: Suitable for a range of applications including dyeing, washing, scouring, bleaching, and fastness testing across various textile materials.- Energy and Resource Conservation: Designed for low liquor ratios (e.g., 1:5 to 1:20), these machines minimize water and chemical usage, promoting sustainable laboratory practices. - Enhanced Safety and Cleanliness: Enclosed beaker systems reduce the risk of spills and exposure to chemicals, ensuring a safer laboratory environment. Typical Applications of Oscillation Type Water Bath Dyeing Machine - Textile Research and Development: Ideal for developing and testing new dye formulations and processes on a small scale before scaling up to production levels. Quality Control: Used in quality assurance laboratories to assess color fastness, dye uptake, and other critical parameters of textile products.- Educational Purposes: Serves as a practical tool in academic settings for teaching dyeing principles and techniques. In summary, the Oscillation Type Water Bath Dyeing Machine is an essential tool in textile laboratories, offering precise control over dyeing parameters, improving efficiency, and ensuring high-quality, reproducible results across various textile materials. Features of Oscillation Type Water Bath Dyeing Machine:- Oscillating Mechanism - Provides back-and-forth movement of beakers for uniform dye penetration and sample agitation.

- Multiple Beaker Capacity - Supports dyeing of 12–24 samples simultaneously, ideal for comparative lab testing.

- Digital Temperature Control - Maintains precise water bath temperature (typically up to 99°C), essential for consistent dyeing.

- Variable Oscillation Speed - Adjustable speed settings (e.g., 50–200 cycles/min) to suit different materials and processes.

- Programmable Settings - Allows setting of temperature, time, and speed for repeatable and automated dyeing cycles.

- Stainless Steel Construction - Corrosion-resistant frame and bath for durability in chemical environments.

- Beaker Safety Holders - Secure placement of beakers to prevent spills and maintain consistent treatment.

- Compact Design - Lab-friendly size for easy integration into research and quality control spaces.

- Low Liquor Ratio Operation - Efficient dyeing using minimal dye bath volume (e.g., 1:5 to 1:20), reducing chemical and water use.

- Quiet and Stable Performance

water bath/Shaker bath Dyeing machine

Electronic wrap reel

Electronic Wrap Reel

Electronic Wrap Reel

Electronic Wrap Reel

Fully Automatic Radio Frequency Dryer

Fully Automatic Radio Frequency Dryer

Fully Automatic Radio Frequency Dryer

Fully Automatic Radio Frequency Dryer

IR Dyeing Machine Dunlin

IR Dyeing Machine Dunlin

IR Dyeing machine Dunlin is Safe, high efficiency, environment friendly, energy saving, optimum for new dyeing small sample machines0 - 3.5 ℃ / min Cooling rate 0.2 - 5 ℃ / min Cooling method Air-cooled Rotation speed 0 - 60 rpm Liquor ratio 1:5 -1:100 Power supply 1∮AC 220V 50/60HZ Dimensions( L x W x H) 670×670×780mm 860×680×780mm Weight 100kg 120kg Standard Accessories Cups 1set

Put the test sample. Cups stand 1set Place where to put cups. Protective glove 1set To avoid to be hurt by HT cups. Model: IF-24SCapacity: 24 pots Brad: DUNLIN Origin: China

Color dyeing tests for various dyestuffs of IR Dyeing machine Dunlin- Step dyeing tests. C. Dispersing, levelling and impregnating test. D. High or low liquor ratio exhausting tests. E. Fabric steak and staining tests. F. Concentration tests and others. Protection and Safety gates to protect. Temperature control accuracy +/- 0.2degree

IR Dyeing machine

Digital Yarn Twist Tester

Digital Yarn Twist Tester

Digital Yarn Twist Tester

Digital Yarn Twist Tester

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated