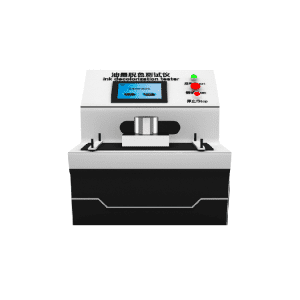

Perspiration Tester

$0.00

Perspiration Tester

Perspiration Tester

A Perspiration Tester is a lab device used to evaluate the colorfastness of textiles to artificial perspiration (sweat). It simulates the effects of human sweat—both acidic and alkaline—on dyed or printed fabrics under controlled temperature and pressure.

Purpose of Perspiration Tester:

– To test how fabrics react to body sweat and determine whether dyes bleed, fade, or transfer onto adjacent materials.

Working Principle:

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

Applications of Perspiration Tester:

– Garment and sportswear testing

– Quality control in textile processing

– Compliance with standards like ISO 105 E04, AATCC 15

Benefits of Perspiration Tester:

- Accurate Sweat Simulation – Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality – Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance – Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

Features of Perspiration Tester:

- Stainless Steel Frame – Corrosion-resistant body for durability and long-term use.

- Multi-Sample Capacity – Can hold up to 20 or more specimens for batch testing.

- Standardized Loading Weight- Applies uniform pressure (usually 12.5 kPa) across all samples.

- Removable Plates – Glass or acrylic plates ensure even contact and easy cleaning.

- Compact Design- Space-saving, bench-top model ideal for lab environments.

- Complies with Test Standards – Meets ISO 105 E04, AATCC 15, and related perspiration fastness standards.

- Ease of Operation – Simple loading, unloading, and incubation process.

- High-Temperature Resistance – Can be used inside incubators at 37°C or ovens as required.

How to Use a Perspiration Tester:

- Prepare the Test Solution – Mix artificial acidic or alkaline perspiration as per standard (ISO or AATCC).

- Cut the Fabric Samples – Cut both the test fabric and adjacent white fabric (usually cotton) to standard size.

- Soak the Samples – Immerse the fabric sandwich (test + adjacent) in the test solution for 30 minutes.

- Remove Excess Liquid – Gently squeeze or blot to remove extra moisture—do not dry.

- Load in the Tester- Place each sandwich between glass or acrylic separator plates in the tester.

- Apply Pressure – Tighten the top plate or place the standard weight on top to apply uniform pressure.

- Incubate – Keep the loaded tester in an oven or incubator at 37°C for 4–16 hours (depending on the method).

- Accurate Sweat Simulation – Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality – Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance – Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Dry and Evaluate – Remove, air dry the samples, then assess color change and staining using a gray scale.

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

Perspiration Tester

Related products

Spray Rating Tester

Spray Rating Tester

Spray Rating Tester

- Quick and Simple Evaluation - Offers a fast way to assess fabric water repellency without complex setup.

- Standardized Testing- Complies with AATCC 22 and ISO 4920, ensuring globally accepted results.

- Cost-Effective- Low maintenance and no power requirement make it economical for routine lab use.

- Improves Fabric Performance - Helps manufacturers develop or improve water-resistant textiles.

- Non-Destructive Test - Does not damage the fabric, allowing for additional tests on the same sample.

- Visual Grading- Easy to interpret using a standard spray rating chart (0 to 100 scale).

- Supports Quality Control - Detects finish degradation or variation in water-repellent treatments.

- Portable and Compact- Lightweight design allows easy use in various lab or field settings.

- Standardized Spray Nozzle - Delivers consistent water spray per AATCC and ISO specifications.

- 45° Specimen Mounting Angle - Ensures uniform test setup for accurate and repeatable results.

- Stainless Steel or Aluminum Frame - Corrosion-resistant and durable for long-term use with water exposure.

- Water Reservoir and Funnel System - Provides precise water volume (usually 250 ml) for each test.

- Graduated Spray Stand- Fixed height (150 mm above specimen) for controlled spray impact.

- Detachable Specimen Holder- Easy loading and removal of fabric samples.

- Compact and Lightweight Design - Portable and convenient for both lab and field testing.

- No Electricity Required - Fully manual operation increases reliability and reduces operating costs.

- Prepare the Sample - Cut fabric to standard size (usually 180 × 180 mm). - Condition the sample if required (21°C, 65% RH for 24 hours).

- Mount the Fabric - Place the fabric on the specimen holder at a 45° angle.

- Fill the Reservoir - Pour 250 ml of distilled water into the upper funnel.

- Start the Test - Release the water through the nozzle; it sprays over the fabric for about 25–30 seconds.

- Inspect the Fabric - After spraying, visually assess the water beading or penetration on the surface.

- Rate the Sample - Compare the fabric’s wetting pattern with the standard spray rating chart: - 100 = No sticking/wetting - 90–50 = Partial wetting - 0 = Complete wetting

- Record the Rating - Document the spray rating for quality control or reporting.

Spray Reting Tester

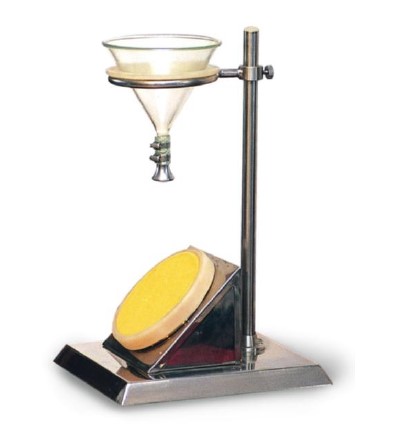

[Scope of application]:

Used for the determination of moisture resistance (wetting grade) of various fabrics

which have been or have not been treated with water resistance or water repellency.

[related standards]:

GB/T4745 ISO4920 AATCC22 JISL1092 etc.

[technical parameters]:

1. Glass funnel:150 x 150 (capacity 500ml)

2. Specimen placement angle:The level is 45 degrees.

3. Distance from nozzle to sample center:150mm

4. Specimen diameter:Ф150mm

5. Size of water receiving pan:500×400×30mm

6. Matching measuring cups:500ml

7, size 500 x 400 x 500mm

8. Instrument weight:5Kg

Spray Reting Tester

[Scope of application]:

Used for the determination of moisture resistance (wetting grade) of various fabrics

which have been or have not been treated with water resistance or water repellency.

[related standards]:

GB/T4745 ISO4920 AATCC22 JISL1092 etc.

[technical parameters]:

1. Glass funnel:150 x 150 (capacity 500ml)

2. Specimen placement angle:The level is 45 degrees.

3. Distance from nozzle to sample center:150mm

4. Specimen diameter:Ф150mm

5. Size of water receiving pan:500×400×30mm

6. Matching measuring cups:500ml

7, size 500 x 400 x 500mm

8. Instrument weight:5Kg VeriVide Colour Assessment Cabinets

VeriVide Colour Assessment Cabinets

VeriVide offers high-quality Colour Assessment Cabinets (CACs) such as the CAC 60-4, CAC 60-5, and CAC 120-4&5. These cabinets, originating from the UK, are reliable tools for visual evaluation in quality assurance, meeting national, international, and retailer standards. They effectively mitigate issues related to color assessment.VeriVide Colour Assessment Cabinets

High-quality visual evaluation tool for quality assurance. Adhering to national, international and retailer standards.Colour Assessment Cabinet's (CACs) reduce problems associated with assessing products or samples in different environments,be though geological or seasonal, offering a cost-effective method to ensure visual accuracy and product quality.

Color Light Box Enhance color precision with VeriVide's cutting-edge Colour Assessment

Cabinets. These cabinets are meticulously designed to ensure accurate color evaluation in various industries. Invest in VeriVide Colour Assessment Cabinets to elevate your color assessment process.

Enhance Color Precision with VeriVide's Cutting-Edge Assessment Cabinets, which meet or surpass ISO 3664 and BS 950 Part 1 international standards. The cabinets are adaptable to user requirements, with lamp options to choose different light sources. Available in 60, 120, and 150cm widths, VeriVide Colour Assessment Cabinets provide a flexible solution for accurate color assessment.

Incorporate user-friendly features like servicing indicator, auto sequence, warm-up, power save and data storage.4 or 5 light source options Versions available for colour fastness testing and particulate testing both adhering to global standardsEnsure that you are using the best equipment available as they provide the best fluorescent D65 daylight simulator, with the highest Colour

Rendering Index (CRI), available. VeriVide Colour Assessment Cabinets products are known as light boxes, viewing booths, colour cabinets and others, depending on which industry or country they are serving in. They are used within a wide array of industry sectors throughout the world including textile and apparel, graphics, automotive, ceramics, cosmetics, pharmacology (CAC Particulate),

food, footwear, packaging and printing.Download the Datasheet below for more information or click 'VeriVide CAC Datasheet Here' to get in touch with colour experts.

VeriVide CAC Datasheet Here Features of VeriVide Colour Assessment Cabinets

• CAC 60, CAC 120 and CAC 150 accommodate 60, 120 and 150cm tubes respectively

VeriVide offers high-quality Colour Assessment Cabinets (CACs) such as the CAC 60-4, CAC 60-5, and CAC 120-4&5. These cabinets, originating from the UK, are reliable tools for visual evaluation in quality assurance, meeting national, international, and retailer standards. They effectively mitigate issues related to color assessment.VeriVide Colour Assessment Cabinets

High-quality visual evaluation tool for quality assurance. Adhering to national, international and retailer standards.Colour Assessment Cabinet's (CACs) reduce problems associated with assessing products or samples in different environments,be though geological or seasonal, offering a cost-effective method to ensure visual accuracy and product quality.

Color Light Box Enhance color precision with VeriVide's cutting-edge Colour Assessment

Cabinets. These cabinets are meticulously designed to ensure accurate color evaluation in various industries. Invest in VeriVide Colour Assessment Cabinets to elevate your color assessment process.

Enhance Color Precision with VeriVide's Cutting-Edge Assessment Cabinets, which meet or surpass ISO 3664 and BS 950 Part 1 international standards. The cabinets are adaptable to user requirements, with lamp options to choose different light sources. Available in 60, 120, and 150cm widths, VeriVide Colour Assessment Cabinets provide a flexible solution for accurate color assessment.

Incorporate user-friendly features like servicing indicator, auto sequence, warm-up, power save and data storage.4 or 5 light source options Versions available for colour fastness testing and particulate testing both adhering to global standardsEnsure that you are using the best equipment available as they provide the best fluorescent D65 daylight simulator, with the highest Colour

Rendering Index (CRI), available. VeriVide Colour Assessment Cabinets products are known as light boxes, viewing booths, colour cabinets and others, depending on which industry or country they are serving in. They are used within a wide array of industry sectors throughout the world including textile and apparel, graphics, automotive, ceramics, cosmetics, pharmacology (CAC Particulate),

food, footwear, packaging and printing.Download the Datasheet below for more information or click 'VeriVide CAC Datasheet Here' to get in touch with colour experts.

VeriVide CAC Datasheet Here Features of VeriVide Colour Assessment Cabinets

• CAC 60, CAC 120 and CAC 150 accommodate 60, 120 and 150cm tubes respectively

- Either 4 or 5 light sources available for each model including D65, D50, 840P15, F and UV - see Lamp Options.• Internal finishes in Munsell N5, Munsell N7 or Grey 5574 • Diffuser and/or dimmer options available Dimensions of VeriVide Colour Assessment Cabinets CAC 60-4 Dimensions (mm) Width Height Depth Overall 710 545 420

Digital Bench top PH Meter

Digital Bench top PH Meter

Digital Bench top PH Meter

Brand: Hanna Model: HI2002 Country of Manufacture: Romania Origin: USA

Digital Bench top PH Meter

Single parameter of Digital Bench top PH Meter features user-friendly tablet design with bench, portable or wall mount options for ultimate flexibility. Switch from portable to bench in the same procedure or clear the surface for easier working and hang on the wall. Digital Bench top PH Meter Range -2.00 to 16.00pH; pH Digital smart electrode compatible Accuracy: ±0.01 pH edge® pH is dedicated to testing pH. Using Hanna's latest innovation in technology and design, edge® can be adapted to suit your working method. Select from hand held, wall mount or bench top - or switch between them all. edge® is happy any which way. Simply plug in the electrode, then play. Measurement is simpler, quicker and more accurate than ever. Results are fast and reliable. Combining high precision technology with the user-friendly dimensions and format of a small digital tablet, edge® is breaking new ground in electrochemistry. This is a must-have meter for your laboratory.| pH Range | basic mode: -2.00 to 16.00 pH; standard mode: -2.000 to 16.000 pH | |

| Resolution | basic mode: 0.01 pH; standard mode: 0.001 pH | |

| Accuracy (@25°C) | basic mode: ±0.01 pH; standard mode: ±0.002 pH | |

| Calibration | basic mode: automatic, up to three points calibration, 5 standard buffers available; standard mode: automatic, up to five point calibration, 7 standard buffers available and two custom buffers | |

| Temperature Compensation | automatic, -5.0 to 100.0°C (using integral temperature sensor) | |

| Electrode Diagnostics | standard mode: probe condition, response time and out of calibration range | |

| mV pH Range | ±1000 mV | |

| Resolution | 0.1 mV | |

| Accuracy (@25°C) | ±0.2 mV | |

| ORP Range | ±2000 mV | |

| Resolution | 0.1 mV | |

| Accuracy (@25°C) | ±0.2 mV | |

| Temperature Range | -20.0 to 120.0°C | |

| Resolution | 0.1°C | |

| Accuracy | ±0.5°C | |

| Additional Specifications: | ||

| Probe | HI-11310 digital glass body pH electrode with 3.5mm connector and 1m cable | |

| Logging | up to 1000 (400 for basic mode) records organised in: manual log-on demand (max. 200 logs), manual log-on-stability (max. 200 logs), interval logging (max. 600 samples; 100 lots) | |

| Connectivity | 1 USB port for storage; 1 micro USB port for charging and PC connectivity | |

| Environment | 0 to 50°C; RH max 95% non-condensing | |

| Power Supply | 5 VDC adapter (included) | |

| Dimensions | 2020 x 140 x 12 mm | |

| Weight | 250 g |

- High Accuracy and Resolution

- Digital Display - Large, clear LCD or LED screen shows pH readings, temperature, and sometimes mV or ion concentration. - Some models include a backlit display for better visibility.

- Electrode System - Uses a pH-sensitive electrode (usually glass) connected to a reference electrode. Electrodes are often replaceable and require regular calibration and maintenance.

- Temperature Compensation - Automatic or manual temperature compensation to correct pH readings based on sample temperature. - Integrated temperature sensors or separate probes are used.

- Calibration Functions - Supports 2-point, 3-point, or multi-point calibration using standard buffer solutions. - Auto-recognition of calibration buffers in advanced models.

- Data Storage and Connectivity - Internal memory for storing results. - USB or RS232 ports for data export to PCs or printers; some models support wireless connectivity.

- Sturdy Design - Benchtop models are larger and more stable than portable meters. - Often come with a durable casing and electrode arm for hands-free operation.

- High Accuracy and Precision

- User-Friendly Interface- Digital displays (LCD/LED) make readings easy to see and interpret.- Many models offer intuitive controls and guided calibration, simplifying operation.

- Advanced Calibration Features- Supports multi-point calibration for improved accuracy across a wide pH range.- Some models automatically recognize buffer solutions, reducing user error.

- Temperature Compensation- Automatic temperature compensation (ATC) corrects readings based on sample temperature, ensuring accuracy.

- Stable and Durable Design- Benchtop units are more robust and stable than handheld devices, reducing the risk of spills or tipping.- Often include electrode holders or arms for secure, hands-free measurements.

- Data Management and Connectivity- Built-in memory for storing measurement data.USB, RS232, or wireless connectivity for exporting data to computers or laboratory information systems (LIS).

- Multi-Functionality- Some models also measure ORP (oxidation-reduction potential), ion concentration, or conductivity.- Suitable for a variety of testing needs beyond just pH.

- Ideal for Long-Term Use- Designed for prolonged and repeated use in laboratory environments.- Replaceable electrodes and parts extend the meter’s usable life.

- Compliance and Documentation- Data logging features support documentation and compliance with regulatory standards in regulated industries (e.g., pharma, food, environmental testing).

Controller For IR Dyeing Machine

Controller For IR Dyeing Machine

IR Dyeing machine controller

- Temperature Control:- Precisely regulates the infrared heaters to maintain uniform temperature across the dye bath. - Supports customizable heating curves (ramp-up, hold, and cool-down phases).

- Programmable Logic Control (PLC): - Allows operators to set and automate dyeing programs for different fabrics and dye types. - Supports multiple recipes or programs for different batches.

- Real-Time Monitoring and Feedback: - Monitors parameters like temperature, fabric rotation, bath circulation, and timing. - Provides real-time data and alarms for deviations.

- Touchscreen Interface / HMI (Human Machine Interface): - User-friendly interface for configuring and monitoring processes. - Multi-language support and graphical display of process curves.

- Data Logging and Traceability: - Records process data for quality control and traceability.

- Energy Efficiency Optimization: - Manages IR heater output to reduce energy usage. - Often includes features for auto shut-off or idle mode.

- Safety Features: - Includes emergency stop, over-temperature protection, and fault detection systems. 8. Connectivity: - Modern controllers may support Ethernet, Modbus, or other industrial communication protocols for integration into factory automation systems.

- Improved Dyeing Accuracy and Consistency

- Enhanced Energy Efficiency- Infrared heating is more energy-efficient than traditional heating methods.- The controller optimizes energy use by adjusting the IR output based on process needs, reducing overall energy consumption.

- Time Savings- Faster heating and cooling cycles due to infrared technology.- Automated processes reduce manual intervention and cycle times. 4. Better Process Control- Programmable dyeing cycles and precise control over each stage (heating, dyeing, rinsing, cooling).- Real-time monitoring and adjustments improve reliability.

- Reduced Water and Chemical Usage- More efficient dye penetration and fixation mean less water and fewer chemicals are needed for reprocessing or corrections.6. Lower Operational Costs

- Enhanced Safety Built-in alarms, emergency shut-off and automatic fault detection enhance operational safety.8. Data Logging and Traceability- Ability to record and review dyeing process data helps in quality control and troubleshooting.- Facilitates compliance with industry standards and audits.

- User-Friendly Operation- Modern touchscreen interfaces make it easier for operators to manage and monitor processes.- Multilingual support and visual feedback enhance usability.

GSM Cutter with Balance

GSM Cutter with Balance

GSM Cutter with Balance

Digital thickness gauge

Digital Thickness Gauge

Digital Thickness Gauge

- High Accuracy - Offers precise measurements, often up to ±0.01 mm, reducing human error.

- Quick Readout - Instant digital display of results speeds up testing and data collection.

- Easy to Use - Simple operation with one-button zeroing and unit conversion.

- Consistent Pressure Application - Spring-loaded foot ensures uniform pressure for repeatable results.

- Multi-Material Testing - Suitable for textiles, paper, film, rubber, leather, and nonwovens.

- Portable and Lightweight- Ideal for both lab and field use with battery-powered operation.

- Data Hold Function - Locks the measurement on-screen for easy recording.

- Improves Quality Control - Helps manufacturers maintain product thickness standards.

- Digital LCD Display - Provides clear, instant thickness readings in mm or inches.

- High Resolution & Accuracy - Typically measures with 0.01 mm precision.

- Spring-Loaded Presser Foot - Applies consistent pressure on samples for reliable results.

- Zero Setting Function- Allows quick reset before each measurement.

- Unit Conversion Button - Easily switch between metric (mm) and imperial (inch) units.

- Data Hold Function - Freezes the displayed value for easy recording.

- Portable Design - Compact and battery-operated for on-site or lab use.

- Durable Construction - Made from stainless steel or hardened materials for long life.

- Auto Power-Off - Saves battery by shutting off when idle.

- Variety of Anvil & Foot Sizes - Customizable based on testing standards or material types.

- Power On the Device - Press the power button to turn on the gauge.

- Zero the Gauge - Close the anvil and presser foot fully. Press the "ZERO" button to reset the display to 0.00 mm.

- Select Unit (if needed) - Use the unit button to toggle between mm and inches.

- Place the Sample - Open the presser foot and insert the material between the foot and anvil.

- Apply Pressure - Gently release the presser foot to let it rest on the sample using its spring force.

- Read the Measurement- Read the thickness displayed on the LCD screen.

- Hold or Record the Data - Use the "HOLD" button (if available) to lock the reading for recording.

- Remove the Sample- Lift the presser foot and take out the material.

- Power Off - Turn off the device or let it auto shut-off.

- Features of Digital Thickness Gauge:

- Digital LCD Display - Provides clear, instant thickness readings in mm or inches.

- High Resolution & Accuracy - Typically measures with 0.01 mm precision.

- Spring-Loaded Presser Foot - Applies consistent pressure on samples for reliable results.

- Zero Setting Function- Allows quick reset before each measurement.

- Unit Conversion Button - Easily switch between metric (mm) and imperial (inch) units.

- Data Hold Function - Freezes the displayed value for easy recording.

- Portable Design - Compact and battery-operated for on-site or lab use.

- Durable Construction - Made from stainless steel or hardened materials for long life.

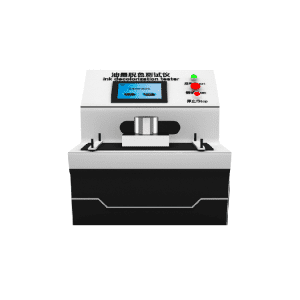

Digital Ink Rubbing Tester

Digital Ink Rubbing Tester

Digital Ink Rubbing Tester

Digital Ink Rubbing Tester

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated