Martindale abrasion tester Updated

$0.00

Martindale abrasion tester updated

Latest Update 1 A+

Martindale Wear-Resistant Instrument

Martindale Wear-Resistant Instrument

Martindale abrasion tester updated purposefully designed to enhance the ease of use and reliability of results Strong and solid base feet to increase instrument stability Sliding pad design reduces noise of motion plate.

Martindale abrasion tester updated Accessible Motion plate storage rack incorporated into the side of the instrument to conserve lab space and allowing full access to all abrasion stations Enhanced sample holders allowing for quicker sample loading Quick-lock couplers facilitate easy access for service and calibration

Martindale abrasion tester updated is a versatile instrument capable of multiple abrasion and pilling tests. It uses precision components to deliver the exact abrasion or pilling movement required by all international and retailer standards. Martindale abrasion tester updated Full Color Touch Screen Controls Most common functions accessible in one or two touches Displays individual station counters Test materials ordering information accessible directly on the instrument display Multi-lingual interface with display options in English, Chinese.

Martindale abrasion tester updated Designed for Adaptability the Martindale Line can perform a variety of abrasion and pilling tests. The user-friendly design allows operators to easily change over testing station configurations with specialized enhancement kits.

Martindale abrasion tester updated can be used for: Fabric Abrasion, Fabric Pilling, Sock, Abrasion, Leather Abrasion, Edge Abrasion, Testing Floor Coverings, Toothbrush Testing’s, Other Specialized Testing’s,

Martindale abrasion tester updated Convenient The compact base is designed to conserve valuable lab space while providing maximum testing capacity. Two sizes available: Larger base can have 4, 6, or 9 test positions Instrument Comes Standard with: Sample Holders 9 kPa and 12 kPa Weights for standard abrasion testing Standard Mounting Device

Martindale abrasion tester updated have Accessory Holder Available separately to conveniently hold martindale accessories while not in use Made from high quality acrylic and designed to be both practical and attractive Quality Test Materials supplies a wide variety of consumables design specifically for testing on the Martindale Abrasion and Pilling Tester.

These high quality consumables will ensure that each test performed is accurate and reliable. Martindale abrasion tester updated Scope of application Its is used for testing the wear resistance, abrasion and appearance change (pilling) of textiles and membrane materials (Martindale method).

Martindale abrasion tester updated Related standard

GB/T 21196 (International Standard Drafting Unit), FZ/T 20020, GB/T 4802.2, GB/T 13775,

ASTM D4966, ASTM D4970, ASTM D3886, ISO 12945.2, ISO 12947, JIS L1096, IWSTM

196/TM112 M&S, etc.

[Instrumentation characteristics]

1. Three test modes, adding and subtracting two counting modes.

2. No turning guide plate design, no need to move the sample.

3. PLC modular control, seven inch color touch screen, Chinese and English double-choice menu operation.

[Technical parameters]

1. Workplace:9 place 666665555

2. Counting range:0-999999 times

3. Maximum travel:60.5±0.5mm 24±0.5mm

4. Pressure mass:

- Clothing sample weight hammer:397±2g

Furniture decoration sample weight hammer:597±2g

C. Stainless steel discs:260±1g - Effective friction diameter of grinding block: Type A 198g(3kpa) friction head 28.8-0.084mm Type B 155g(1.52N) friction head 90-0.10mm

6. Relative velocity of gripper and grinding table:50 + 2R / MI (20-70r / min adjustable)

7. Sampling hammer quality:2385±10g 8. Shape size:870×580×300mm 9. power supply:AC220V 50Hz 500W 10.Weight:73KG. - [Standard accessories]

Items and specifications Qty Notes Main machine 1Power cable 1A type 198g Friction head 9 B type 155g(1.52N) Friction head 9 597g Hammer 9 397g Hammer 9, 666666666

260g Stainless steel disc 9, 2385g Holding hammer 1,B Friction head felt 18 ¢90mm

Steel ball 6, Rubber ring 18, Inner Hexagonal Wrench 1 - Sampler 1, Fuse 2 3A, Standard felt 18, Weight:750±50g/m2, Thickness:2.5±0.5mm, Standard foam lining 40, Density:0.03g/cm3,Thickness:3mm,Standard abrasive 9

Circular shear template Each φ140mm、φ38mm,Small screw knife 1, Bottom foot 4

Related products

Fatigue tester for Elastic fabric

Fatigue Tester for Elastic Fabric

Fatigue tester for Elastic fabric

- Adjustable Stretch Range - Allows setting stretch levels (e.g., 0–100%) to simulate real-life fabric use.

- High-Cycle Capability - Supports up to millions of stretch-relax cycles for long-term fatigue analysis.

- Touch Screen Control - 7-inch color display for easy setup, monitoring, and data entry.

- Servo Motor Driven - Ensures precise and smooth linear motion during testing.

- Customizable Speed - Adjustable test speed (e.g., up to 40 cycles per minute) based on test requirements.

- Multi-Sample Testing - Some models allow testing multiple specimens simultaneously.

- Cycle Counter with Alarm - Built-in counter with programmable stop after preset cycles and auto-alert feature.

- Durable Construction - Robust metal frame suitable for continuous testing in lab environments.

- Standard Compliance - Designed to follow standards like GB/T 37635 for elastic fabric testing.

- Prepare the Sample

- Mount the Sample - Secure both ends of the fabric in the upper and lower clamps.

- Set Test Parameters

- Start the Test - Press start on the touch screen interface. - The machine will cyclically stretch and release the sample.

- Monitor Progress - Observe operation or let it run automatically.

- Remove and inspect - Take out the fabric and measure elongation, recovery, or visual defects.

- Record and Compare Results - Compare with initial measurements or standard performance criteria.

Fatigue tester for Elastic fabric

Hydraulic GSM Cutter

Hydraulic GSM Cutter

Hydraulic GSM Cutter

- High Cutting Precision - Ensures consistent and accurate fabric sample size for reliable GSM results.

- Effortless Operation- Hydraulic action reduces manual effort and operator fatigue.

- Ideal for Thick or Multi-Layer Fabrics - Cuts through dense or multiple fabric layers cleanly.

- Time-Saving - Speeds up the sample preparation process, especially for high-volume testing.

- Improves Test Accuracy - Uniform samples help eliminate errors in GSM calculation.

- Durable and Long-Lasting - Robust construction ensures stability and extended service life.

- Safety Enhancement - Reduces risk of injury compared to manual rotary cutters.

- Consistent Pressure Application - Hydraulic mechanism maintains steady force for each cut.

- Hydraulic Press Mechanism - Applies consistent and strong pressure for clean, even cuts.

- Standard Cutting Die (100 cm²) - Produces fabric samples suitable for GSM testing with standard area.

- Heavy-Duty Construction - Built with robust metal frame for long-term lab or industrial use.

- Sharp Stainless Steel Blades - Durable and replaceable blades ensure smooth, precise cuts.

- Cutting Pad Included - Comes with a rubber or nylon base to protect blades and ensure clean edges.

- Simple Lever or Button Operation - Easy to use with minimal training required.

- Non-slip Base - Provides stability during operation for safe, accurate cutting.

- Supports Various Fabric Types

- Place the Cutting Pad - Lay the rubber or nylon cutting pad on a flat surface.

- Position the Fabric - Place the fabric sample flat and smooth on the cutting pad.

- Align the Cutter - Position the GSM cutter die over the desired area of the fabric.

- Activate Hydraulic Press - Pull the lever or press the button to apply hydraulic pressure and cut the sample.

- Remove the Sample - Lift the cutter and carefully take out the circular fabric piece (usually 100 cm²).

- Weigh the Sample - Place the cut sample on a precision balance or GSM scale to determine weight.

- Calculate GSM - Multiply the sample weight (in grams) by 100 to get GSM.

Hydraulic GSM Cutter

GSM Cutter with Balance

GSM Cutter with Balance

GSM Cutter with Balance

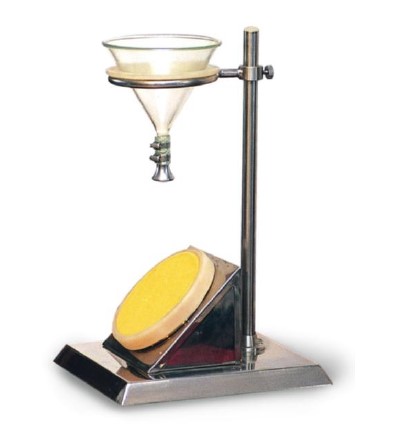

Fiber Oil Fast Extractor

Fiber Oil Fast Extractor

A Fiber Oil Fast Extractor is a laboratory instrument designed to determine the oil or finish content in fibers, yarns, or fabrics, particularly wool and synthetic materials. It operates on the principle of solvent extraction followed by evaporation. Working Principle of Fiber Oil Fast Extractor:- Sample Preparation: Cut the fabric or fiber into small pieces.

- Solvent Addition: Place the sample into a metal tube and add an appropriate solvent (e.g., petroleum ether, ethyl ether).

- Extraction: Apply weight to the sample to facilitate the dissolution of oils into the solvent.

- Evaporation: The solvent-oil mixture drips onto a heated plate where the solvent evaporates, leaving behind the oil.

- Measurement: Weigh the remaining oil and calculate its percentage relative to the initial sample mass.

- Accurate Oil Content Measurement- Precisely determines oil or finish content in fibers, crucial for quality control.

- Rapid Extraction Process - Delivers fast results, improving lab efficiency and productivity.

- Simultaneous Multi-Sample Testing - Multiple workstations (e.g., 4 at once) reduce testing time for bulk samples.

- Improved Product Quality - Helps maintain consistent oil levels, which affect dyeing, processing, and fabric performance.

- Automatic Operation - Automated pressing and heating reduce manual effort and operator error.

- Digital Monitoring - Built-in timer, temperature control, and oil calculator enhance accuracy and usability.

- Compliance with Standards - Supports industry methods like GB/T 6504-2017, ensuring reliable and standard-compliant results.

- Safe Solvent Handling - Enclosed design minimizes solvent exposure and evaporation loss.

- Multiple Test Stations - Usually equipped with 2 to 4 independent work units for parallel testing.

- Automatic Weight Pressing System - Applies consistent pressure on samples for uniform solvent extraction.

- Microcomputer Temperature Control - Maintains precise heating (typically 90–120°C) with ±1°C accuracy.

- Built-in Timer and Calculator - Allows setting extraction time and calculates oil content directly.

- Solvent Evaporation Plate- Heats and evaporates solvent quickly, leaving only the oil residue.

- Digital Display - Shows time, temperature, and process status for user-friendly operation.

- Compact and Durable Design - Made with corrosion-resistant materials suited for chemical handling.

- Safety Features - Includes overheat protection and enclosed solvent chamber to reduce exposure risk.

- Standard Compliant - Designed to meet GB/T 6504-2017 and similar industry testing standards.

- Prepare the Sample - Cut 5–10 g of fiber or yarn into small pieces and place in the sample tube.

- Add Solvent - Pour a suitable solvent (e.g., petroleum ether) into the tube to cover the sample.

- Apply Weight - Place the extractor's weight or press system onto the sample to aid extraction.

- Start Extraction - Activate the machine. The solvent dissolves the oils and flows to the heating plate.

- Heat for Evaporation - Set the temperature (typically 90–120°C). The solvent evaporates, leaving oil on the plate.

- Measure Oil Content- After drying, weigh the remaining oil. Use the built-in calculator or formula:

- Clean the Unit - After cooling, clean all parts to prepare for the next test.

Fiber Oil Fast Extractor

Fabric Stiffness Tester

Fabric Stiffness Tester

Fabric Stiffness Tester is a lab instrument used to measure the stiffness or flexural rigidity of fabric materials. It evaluates how resistant a fabric is to bending, which influences its drape, comfort, and handling characteristics. Purpose of Fabric Stiffness Tester: To determine the stiffness of textiles by measuring the bending length and calculating flexural rigidity, often using methods like the Cantilever Test (as per ASTM D1388 or ISO 9073-7). Working Principle of Fabric Stiffness Tester: A fabric strip is slid over a horizontal platform until its free end bends under its own weight to a specific angle (usually 41.5°). The length at which this occurs is used to calculate bending length and stiffness. Main Components of Fabric Stiffness Tester: - Test Platform: Flat surface for sample movement. - Graduated Scale: Measures the overhanging length of fabric. - Angle Indicator: Guides the measurement based on standard deflection angle. - Fabric Clamp or Guide: Helps place and move the sample smoothly. Applications of Fabric Stiffness Tester: - Apparel fabrics (e.g., for comfort and drape analysis) - Technical textiles (e.g., automotive, medical fabrics) - Paper, nonwovens, and films Benefits of Fabric Stiffness Tester:- Accurate Measurement of Flexibility - Provides reliable data on fabric stiffness, essential for quality control and product development.

- Improves Product Comfort - Helps assess how soft or rigid a fabric will feel in clothing or furnishings.

- Supports Material Selection - Aids designers and engineers in choosing the right fabric for specific applications based on stiffness.

- Quality Assurance - Detects fabric inconsistencies or defects that affect handling or drape.

- Standards Compliance - Enables testing as per international standards like ASTM D1388 and ISO 9073-7 for global product approval.

- Quick and Simple Operation - Delivers fast results with minimal operator training or preparation.

- Applicable to Multiple Materials - Suitable for woven, nonwoven, knitted fabrics, paper, and films.

- Enhances R&D Accuracy - Supports consistent material testing during product innovation and textile finishing.

- Graduated Measurement Scale - Precise scale to measure overhang length for accurate stiffness calculation.

- Flat Test Platform - Smooth, level surface ensures consistent and reliable fabric movement.

- Standard Deflection Angle Guide - Built-in 41.5° angle reference for consistent stiffness testing (per ASTM/ISO).

- Manual or Motorized Models - Available in both types for simple or automated operation depending on lab needs.

- Compact Design - Space-saving unit ideal for textile labs and quality control rooms.

- Sample Holder or Clamp - Ensures correct alignment and smooth feeding of fabric strips during testing.

- Durable Construction - Made of corrosion-resistant materials like stainless steel or aluminum for long-term use.

- Compliance with Standards - Supports methods like ASTM D1388, ISO 9073-7 for stiffness testing of fabrics.

- Lightweight and Portable - Easy to move and use in various lab settings.

- Low Maintenance - Simple mechanical parts require minimal servicing.

- Prepare the Sample - Cut the fabric into a rectangular strip (e.g., 25 mm × 200 mm), as per standard.

- Place the Sample - Lay the fabric strip flat on the test platform with one end aligned at the zero mark.

- Slide the Fabric - Gently push the fabric forward so it slowly overhangs the platform.

- Watch for Deflection - Stop sliding when the free end of the fabric bends down to the reference angle (typically 41.5°).

- Read the Bending Length - Measure the overhang distance from the scale. This is the bending length (C).

- Calculate Flexural Rigidity

- Repeat for Accuracy - Test both warp and weft directions and average the results for better accuracy.

Scope of application

It is used to measure the stiffness of cotton,

wool, silk, linen, chemical fibers and other woven fabrics,

knitted fabrics, general nonwovens, coated fabrics, etc.

It is also suitable for measuring the stiffness of paper,

leather, film and other flexible materials.

Relevant Standards

GB/T 18318, ASTM D 1388, IS09073-7, BS EN22313 etc.

[Instrument Characteristics]

1. Infrared photoelectric invisible inclined plane

detection system replaces the traditional tangible inclined plane,

realizes non-contact detection, and overcomes the problem that

the measurement accuracy is affected by

the sample torsion lifted by the inclined plane.

2. The inclination adjustable mechanism of instrument

measurement to meet different test requirements.

3. Stepping motor drive, accurate measurement, smooth operation;

4. The color touch screen display can show the extended length,

bending length, bending stiffness of the sample, the warp average,

the weft average and the total average of the above values respectively.

5. Printing of Chinese report forms for thermal printers.

Technical parameters

1. Test methods: The two method (A method: Weft test, B method: Forward and backward test)

2. Measurement angle:41.5 degree, 43 degree and 45 degree adjustable

3. Extend the length range:5-220 mm (special requirements can be made at the time of ordering)

4. Length resolution:0.01mm

5. Measurement accuracy:±0.1mm

6. Specimen specifications:250×25mm

7. Work platform specifications:250×50mm

8. Specification of sample pressing plate:250×25mm

9. Pushing speed of press plate:3 mm/s; 4 mm/s; 5 mm/s

10. Display output: Touch screen display

11. Print Output: Chinese Report

12. Data Processing Volume: A total of 15 groups, each group less than 20 trials

13. Printer: Thermal printer

14, power supply:AC220V 50Hz

15. Host volume:570mm×360mm×490mm

16. Host weight:20kg

Scope of application

It is used to measure the stiffness of cotton,

wool, silk, linen, chemical fibers and other woven fabrics,

knitted fabrics, general nonwovens, coated fabrics, etc.

It is also suitable for measuring the stiffness of paper,

leather, film and other flexible materials.

Relevant Standards

GB/T 18318, ASTM D 1388, IS09073-7, BS EN22313 etc.

[Instrument Characteristics]

1. Infrared photoelectric invisible inclined plane

detection system replaces the traditional tangible inclined plane,

realizes non-contact detection, and overcomes the problem that

the measurement accuracy is affected by

the sample torsion lifted by the inclined plane.

2. The inclination adjustable mechanism of instrument

measurement to meet different test requirements.

3. Stepping motor drive, accurate measurement, smooth operation;

4. The color touch screen display can show the extended length,

bending length, bending stiffness of the sample, the warp average,

the weft average and the total average of the above values respectively.

5. Printing of Chinese report forms for thermal printers.

Technical parameters

1. Test methods: The two method (A method: Weft test, B method: Forward and backward test)

2. Measurement angle:41.5 degree, 43 degree and 45 degree adjustable

3. Extend the length range:5-220 mm (special requirements can be made at the time of ordering)

4. Length resolution:0.01mm

5. Measurement accuracy:±0.1mm

6. Specimen specifications:250×25mm

7. Work platform specifications:250×50mm

8. Specification of sample pressing plate:250×25mm

9. Pushing speed of press plate:3 mm/s; 4 mm/s; 5 mm/s

10. Display output: Touch screen display

11. Print Output: Chinese Report

12. Data Processing Volume: A total of 15 groups, each group less than 20 trials

13. Printer: Thermal printer

14, power supply:AC220V 50Hz

15. Host volume:570mm×360mm×490mm

16. Host weight:20kg Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

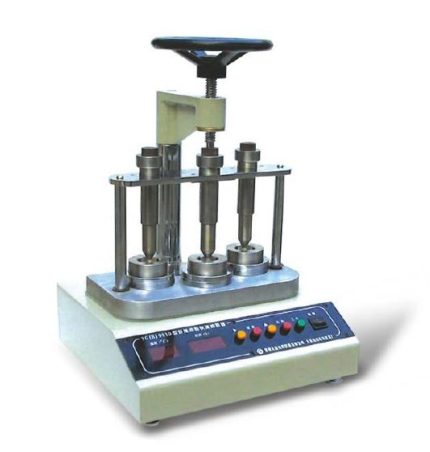

Bursting strength tester

Bursting strength tester

true burst

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

- Bursting pressure can reach up to 1.2MPa 5. The maximum burst and expansion degree can reach 70mm. 6. Strengthen the lighting system on the test surface. 7. The main aerodynamic force helps to clamp the sample system. 8. A variety of test areas are available, and the switching is easy.

- A variety of unit conversions between Chinese and English. 10. Reliable anti-pinch safety protection design. [Technical parameter]: 1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized) 2. The minimum graduation value: 0.0001Mpa 3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree pressurization.

Stretch Recovery Tester Static Method

Stretch Recovery Tester Static Method

Stretch Recovery Tester

- A sample is stretched to a predetermined extension or force.

- The stretch is maintained for a set period.

- After removing the load, the recovery (return to original length) is measured after a fixed time.

- The fabric sample is clamped and stretched to a specific length or force.

- It’s held for a fixed duration (e.g., 1–5 minutes).

- The tension is released, and the sample is allowed to recover.

- The recovered length is measured after a set time.

Stretch Recovery Tester

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated