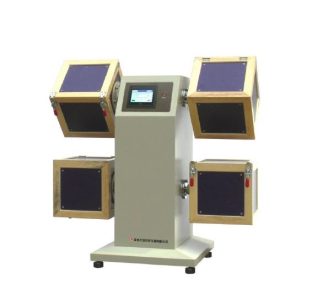

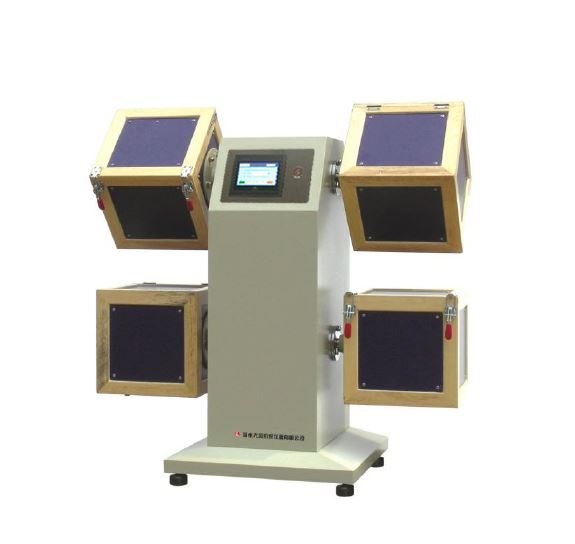

ICI Pilling & Snagging Test Machine

An ICI Pilling & Snagging Test Machine is a specialized laboratory instrument designed to evaluate the resistance of textile fabrics to pilling and snagging, which are common surface defects caused by wear and friction. This tester is widely used in quality control and research and development within the textile industry to ensure fabric durability and appearance retention.

The ICI Pilling & Snagging Test Machine simulates the mechanical action that fabrics undergo during actual wear. Test specimens are mounted on polyurethane tubes and placed inside cork-lined boxes. These boxes rotate at a specified speed, causing the specimens to tumble and rub against the cork lining and themselves, thereby replicating the conditions that lead to pilling and snagging

Digital Control Panel: Equipped with a user-friendly interface, often featuring a touchscreen display for setting test parameters and monitoring progress.

– Detachable Cork Liners: Cork liners inside the boxes are removable, facilitating easy replacement and maintenance. – Compliance with International Standards: Designed to meet various testing standards, including ISO 12945-1, BS 5811, JIS L1076, and IWS TM152, ensuring reliable and comparable results.

✅ Benefits of ICI Pilling & Snagging Test Machine:

– Accurate Simulation of Wear Conditions: Replicates the mechanical stresses that fabrics experience during actual use, providing realistic assessments of pilling and snagging tendencies.

– Enhanced Quality Control: Enables manufacturers to identify and address potential issues in fabric durability before products reach the market.

– Versatility: Suitable for testing a wide range of fabrics, including woven and knitted materials, under various conditions.

– Efficient Testing Process: Multiple specimens can be tested simultaneously, increasing throughput and productivity in laboratory settings.

Typical Applications

– Textile Manufacturing: Assessing the durability of fabrics during the development of new materials or quality assurance of existing products. Research and Development: Studying the effects of different yarns, weaves, and finishes on fabric performance. – Quality Assurance: Ensuring that fabrics meet specified standards for pilling and snagging resistance before mass production.

In summary, the ICI Pilling & Snagging Tester is an essential tool in the textile industry for evaluating the surface durability of fabrics. Its ability to simulate real-life wear conditions and provide standardized assessments helps manufacturers and researchers ensure the quality and longevity of textile products.

Features of ICI Pilling & Snagging Test Machine:

- Multiple Test Stations – Typically available in 2, 4, 6 & more -box configurations for simultaneous testing of multiple samples.

- Rotating Pilling Boxes – Cork-lined boxes rotate at a fixed speed (usually 60 ± 2 rpm) to simulate wear and friction.

- Adjustable Timer – Digital timer allows precise control over test duration (usually up to 9999 cycles).

- Detachable Cork Liners – Easily replaceable liners to maintain consistent friction surfaces and accurate results.

- Standard Tubes & Sample Holders- Polyurethane or foam-covered tubes hold fabric samples in a consistent shape during testing.

- Digital Display or Touch Panel – User-friendly interface for setting speed, cycle count, and monitoring progress.

- Compact and Sturdy Design – Built to withstand long testing cycles and minimize vibration.

- Compliance with International Standards – Supports ISO 12945-1, BS 5811, JIS L1076, IWS TM152, etc.

- Low Noise Operation – Engineered for quiet performance in lab environments.

- Safety Features – Includes secure locking system on doors and overload protection.

How to Use ICI Pilling & Snagging Test Machine:

- Prepare Samples – Cut fabric specimens to standard size (typically 125 mm × 125 mm).

– Mount each sample around a polyurethane tube and secure it with elastic bands or ties.

- Load into Pilling Boxes – Place each prepared tube into the cork-lined rotating boxes of the machine.

- Set Test Parameters – Use the digital control panel to set the number of revolutions (e.g., 7200 for ISO 12945-1) and speed (usually 60 ± 2 rpm).

- Start the Test- Close the box lids securely and press “Start.” The boxes will rotate, tumbling the samples inside.

- Monitor Progress – The timer counts down the set cycles. No need for manual supervision during the run.

- End of Test – Machine stops automatically when the cycle count is reached. Open the boxes and remove the tubes.

- Evaluate Results – Remove the fabric from the tubes and visually assess pilling or snagging using standard photographic rating scales (e.g., ASTM D3512, ISO 12945)

- Clean the Machine – Remove lint and debris from cork liners and clean tubes if needed.

Tip: Always ensure samples are mounted uniformly to avoid inconsistent results.

Use ICI Pilling & Snagging Test Machine

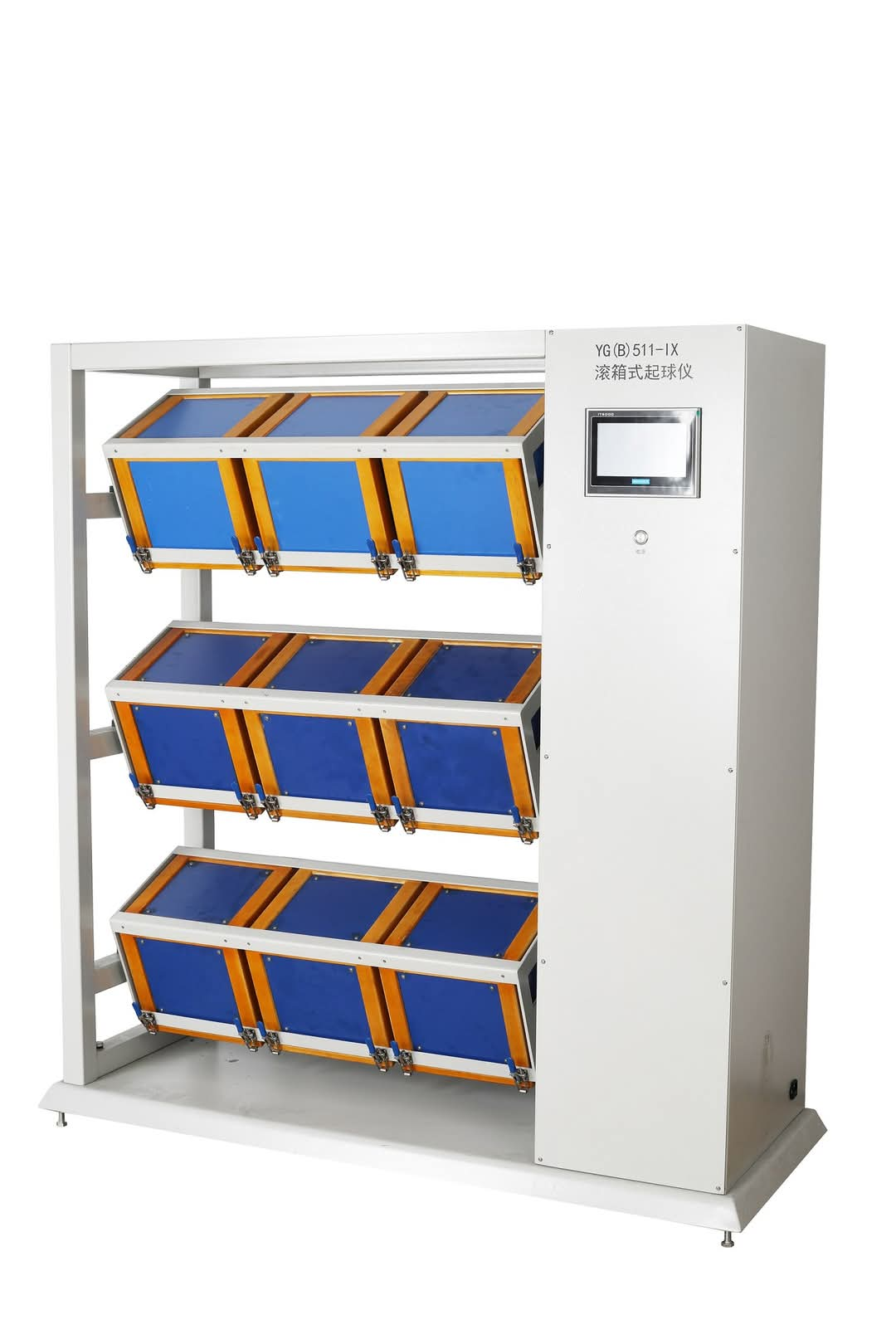

Rolling Pilling Tester

series rolling Pilling Resistance tester

type rolling Pilling Resistance instrument

[Scope of application] It is used for testing the pilling degree of fabrics (especially wool knitted fabrics) under no pressure.

[Related standards]:GB/T4802.3 ISO12945.1 JIS L1076 IWS TM152 BS5811 etc.

[Instrument characteristics]

1. color touch screen menu operation in Chinese.

2. AC servo motor quiet driving, adjustable speed.

3. Inner village rubber cork adopts detachable design.

4. Contactless photoelectric counting, liquid crystal display.

Technical parameters of ICI Pilling & Snagging Test Machine:

Model: Number of pilling boxes

2 4 6 9

Inter Size: 225×225×225mm

Rotating speed of box: 60±2r/min

Counting range: The 1~99999 time

[Sample carrying tube]:

1: The shape is 31.5 x 140 mm weight 52.25g.

2: 4 root / box

Power Supply: Ac 220V±10% 50Hz 120W

Outline size (mm): 930×500×580, 930×500×950, 930×500×1410, 1260×560×1470

Weight (Kg): 60 65 125 165

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated

[Scope of application]:

It is used to test the fuzzing and pilling

performance of the fabric under the condition of

free rolling and friction in the drum.

[Related standards]:

GB/T4802.4 (Standard Drafting Unit)

ISO12945.3, ASTM D3512, ASTM D1375, DIN 53867, ISO 12945-3, JIS L1076, etc.

[Technical parameter]:

1. Number of boxes: 4

2. Roller specifications: diameter (146±1.0) mm, depth (152.4±1.0) mm;

3. Lining material: polychloroprene lining thickness (3.2±0.4) mm. , Hardness (60~70)

IRHD;

4. Impeller specifications: φ12.7 mm×120.6 mm;

5. Plastic blade specifications: 10 mm×65 mm;

6. Rotation speed: 1~2400 rpm can be set freely

7. Working pressure: 14kPa~21kPa;

8. Time counting: (1~999) min.

9. Power supply: AC220V±10% 50Hz 80W

10. Appearance: (480×400×680)mm

11. Weight: 40kg

[Standard accessories]

Items and specifications Qty. Note

Fuse 2 3A

Main machine 1

Power cable 1

Air tube 1 Φ8mm

Grey cotton sliver 4

Cork lining 4

Rating sample photo 1

White glue 1

[Scope of application]:

It is used to test the fuzzing and pilling

performance of the fabric under the condition of

free rolling and friction in the drum.

[Related standards]:

GB/T4802.4 (Standard Drafting Unit)

ISO12945.3, ASTM D3512, ASTM D1375, DIN 53867, ISO 12945-3, JIS L1076, etc.

[Technical parameter]:

1. Number of boxes: 4

2. Roller specifications: diameter (146±1.0) mm, depth (152.4±1.0) mm;

3. Lining material: polychloroprene lining thickness (3.2±0.4) mm. , Hardness (60~70)

IRHD;

4. Impeller specifications: φ12.7 mm×120.6 mm;

5. Plastic blade specifications: 10 mm×65 mm;

6. Rotation speed: 1~2400 rpm can be set freely

7. Working pressure: 14kPa~21kPa;

8. Time counting: (1~999) min.

9. Power supply: AC220V±10% 50Hz 80W

10. Appearance: (480×400×680)mm

11. Weight: 40kg

[Standard accessories]

Items and specifications Qty. Note

Fuse 2 3A

Main machine 1

Power cable 1

Air tube 1 Φ8mm

Grey cotton sliver 4

Cork lining 4

Rating sample photo 1

White glue 1

burning of flammable textile materials after ignition.

(specific ignition nozzles and sample holders can be customized to meet multiple criteria).

Related standards

GB/T14644 ASTM D1230 CFR1610 etc.

Technical parameters

1. The spread of time:0 ~ 999.9S resolution 0.1S

2. The temperature inside the box shows:Room temperature -99 degrees C resolution 1 c

3. Igniting time:1S

4. Type of igniter:4 1/2 syringe

5. Sample clip size:Outer frame:204mm * 78mm inner frame:152mm×38mm

6. Distance from the top of the igniter to the sample surface:8mm

7. Studio size and outline size

Studio size:370mm×220mm×350mm

Outline size:375mm×245mm×478mm

8. Power supply:AC220V 50Hz 20W

9. Weight:18Kg

burning of flammable textile materials after ignition.

(specific ignition nozzles and sample holders can be customized to meet multiple criteria).

Related standards

GB/T14644 ASTM D1230 CFR1610 etc.

Technical parameters

1. The spread of time:0 ~ 999.9S resolution 0.1S

2. The temperature inside the box shows:Room temperature -99 degrees C resolution 1 c

3. Igniting time:1S

4. Type of igniter:4 1/2 syringe

5. Sample clip size:Outer frame:204mm * 78mm inner frame:152mm×38mm

6. Distance from the top of the igniter to the sample surface:8mm

7. Studio size and outline size

Studio size:370mm×220mm×350mm

Outline size:375mm×245mm×478mm

8. Power supply:AC220V 50Hz 20W

9. Weight:18Kg

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.)

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.)

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm