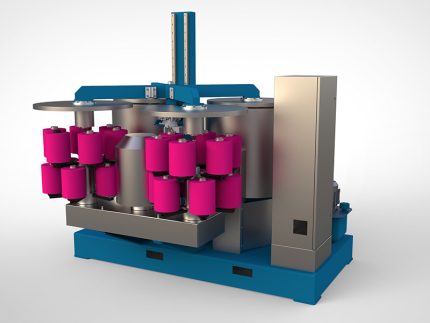

Automatic Bobbin Hydro extractor

Automatic Bobbin Hydro extractor

Automatic Bobbin Hydro extractor

- Computer system: Foshan HuaGao Chinese English computer, equipped with LG PLC.

- Electromagnetic valve: Ningbo Jiaerling

- Frequency converter: Use Made in China frequency converters.

- Pump: self-made high head and large flow centrifugal water pump.

- Main pump motor: Anhui Wannan Motor.

- Master cylinder liquid level: Use 4-20mA analog signal output.

- Level of deputy temporary worker: use foam water level gauge. (American Mike)

- Temperature detection and display: digital temperature display instrument, dual temperature measuring probes.

- The safety system has a triple cylinder head safety interlock mechanism, and the main cylinder is equipped with a stainless

- steel safety valve.

- Heat exchanger: external spacer heating.

- Feeding system: Quantitative feeding based on the process curve.

- Circulation system: The main pump flows internally and externally, which is automatically controlled by a computer or manually controlled by a relay.

- Valves: Y valves are used for heating, stainless steel Y valves are used for single inlet and single row, and other Y valves are produced by joint ventures.

- Temperature control: on-off temperature control, controlled by a computer, with automatic heating, cooling, and insulation functions.

- Dyeing method: air cushion type.

- Opening method: manual opening.

- Surface treatment: polishing inside and outside the cylinder.

- Cage: Each dyeing machine is equipped with butterfly blades and self-locking locks.

- Body plate: high-quality stainless steel. (S31603)

- Bath ratio: 1:5-1:6

- Chemical material system: including heating and water adding functions, including overflow type salt melting device.

- Overflow cleaning: The cleaning port is installed on the upper part of the cylinder port, and the bottom of the cylinder is filled with water, while the cylinder is drained for easy cleaning.

- Commutation method: Novel "U" type commutation.

- Random accessories: Each model comes with one set of mechanical seals, pot mouth rings, and reversing seals for the main and auxiliary pumps.

Automatic Bobbin Hydro extractor

Thread Cone Winding Machine

Thread Cone Winding Machine

Thread Cone Winding Machine

- Efficient Yarn Packaging - Speeds up the process of preparing thread for sewing or embroidery.

- Uniform Cone Formation - Ensures consistent cone shape and tension for smooth downstream use.

- Reduces Thread Breakage - Controlled tension and smooth guiding minimize thread damage.

- Time & Labor saving- Automates winding, reducing manual effort and increasing productivity.

- Improves Thread Quality - Removes loose fibers and irregularities during winding.

- Supports Multiple Yarn Types - Compatible with cotton, polyester, silk, and blended threads.

- Adjustable Winding Speed - Variable speed control for different thread types.

- Thread Tension Control System - Maintains consistent tension for smooth winding.

- Auto Stop Mechanism - Stops automatically when cone is full or thread breaks.

- Multiple Spindle Options - Single or multi-spindle designs for higher output.

- Traverse Mechanism - Ensures even layering of thread across the cone.

- Compact & Durable Build - Space-saving, long-lasting structure for industrial use.

- Set Up the Machine - Turn on the power and check all safety covers and switches.

- Load the Yarn Source - Place the yarn hank, bobbin, or spool on the supply holder.

- Mount the Empty Cone - Fix an empty cone securely onto the spindle.

- Thread the Machine - Guide the thread through tension disks, guides, and eyelets as per the machine path.

- Adjust Settings - Set the desired winding speed and tension based on thread type.

- Start the Machine - Press the start button; the thread begins winding onto the cone.

- Monitor the Process - Ensure even winding and tension; adjust traverse if needed.

- Auto-Stop or Manual Stop - The machine will stop automatically if the cone is full or thread breaks.

- Remove the Cone - Carefully remove the finished cone and load a new one if needed.

- Clean and Shut Down - Turn off the machine and clean any thread residue after use.

- Always Use Safety Guards - Ensure all protective covers are in place before operation.

- Avoid Loose Clothing - Prevent thread or moving parts from catching clothes or jewelry.

- Power Off Before Maintenance - Always turn off the machine before threading, cleaning, or adjustments.

- Check Thread Path - Use correct threading to prevent sudden breakage or tangling.

- Don’t Overload the Cone - Stop the machine once the cone is adequately filled to avoid jamming.

- Keep Area Clean - Remove lint and thread waste regularly to prevent fire hazards or machine faults.

- Daily Cleaning - Wipe dust and thread particles from guides, spindles, and tension parts.

- Lubrication - Oil moving parts (as per manual) weekly to reduce wear.

- Check Tension Settings - Inspect and calibrate tension mechanisms for consistent winding.

- Inspect Belts and Motors - Look for wear or looseness in drive belts and check motor sound regularly.

- Replace Worn Parts Promptly - Replace traverse mechanisms, springs, or tension disks if worn out.

Thread Cone Winding Machine

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated