VeriVide Colour Assessment Cabinets

$0.00

VeriVide Colour Assessment Cabinets

VeriVide offers high-quality Colour Assessment Cabinets (CACs) such as the CAC 60-4, CAC 60-5, and CAC 120-4&5. These cabinets, originating from the UK, are reliable tools for visual evaluation in quality assurance, meeting national, international, and retailer standards. They effectively mitigate issues related to color assessment.VeriVide Colour Assessment Cabinets

High-quality visual evaluation tool for quality assurance. Adhering to national, international and retailer standards.Colour Assessment Cabinet’s (CACs) reduce problems associated with assessing products or samples in different environments,be though geological or seasonal, offering a cost-effective method to ensure visual accuracy and product quality.

Color Light Box Enhance color precision with VeriVide’s cutting-edge Colour Assessment

Cabinets. These cabinets are meticulously designed to ensure accurate color evaluation in various industries. Invest in VeriVide Colour Assessment Cabinets to elevate your color assessment process.

Enhance Color Precision with VeriVide’s Cutting-Edge Assessment Cabinets, which meet or surpass ISO 3664 and BS 950 Part 1 international standards. The cabinets are adaptable to user requirements, with lamp options to choose different light sources. Available in 60, 120, and 150cm widths, VeriVide Colour Assessment Cabinets provide a flexible solution for accurate color assessment.

Incorporate user-friendly features like servicing indicator, auto sequence, warm-up, power save and data storage.4 or 5 light source options Versions available for colour fastness testing and particulate testing both adhering to global standardsEnsure that you are using the best equipment available as they provide the best fluorescent D65 daylight simulator, with the highest Colour

Rendering Index (CRI), available. VeriVide Colour Assessment Cabinets products are known as light boxes, viewing booths, colour cabinets and others, depending on which industry or country they are serving in. They are used within a wide array of industry sectors throughout the world including textile and apparel, graphics, automotive, ceramics, cosmetics, pharmacology (CAC Particulate),

food, footwear, packaging and printing.Download the Datasheet below for more information or click ‘VeriVide CAC Datasheet Here’ to get in touch with colour experts.

VeriVide CAC Datasheet Here Features of VeriVide Colour Assessment Cabinets

• CAC 60, CAC 120 and CAC 150 accommodate 60, 120 and 150cm tubes respectively

- Either 4 or 5 light sources available for each model including D65, D50, 840P15, F and UV – see Lamp Options.• Internal finishes in Munsell N5, Munsell N7 or Grey 5574

• Diffuser and/or dimmer options available Dimensions of VeriVide Colour Assessment Cabinets

CAC 60-4 Dimensions (mm) Width Height Depth Overall 710 545 420

Viewing Area 680 360 380 CAC 60-5 Dimensions (mm) Width Height Depth Overall 710 545 540 Viewing Area 680 360 495 CAC 120-4 and CAC 120-5 Dimensions (mm) Width Height DepthOverall 1290 755 620 Viewing Area 1260 570 585 CAC 150-4 and CAC 150-5

Dimensions (mm) Width Height Depth Overall 1560 755 620 Viewing Area 1530 570 585 Lamp Options of VeriVide Colour Assessment Cabinets Features of VeriVide Colour Assessment Cabinets Lamp specifications: CIE Daylight Illuminants Light Source Name Lamp Description C.R.I. Length Watts Diam Product Code D75 VeriVide D75 “Artificial Daylight” Correlated

colour temperature 7500K. Conforming to the USA ASTM (American Society for Testing and Materials) D1729-82 standard for D75 Illuminant. With high CIE specifications, for accurate colour matching. 96 600mm 20w T12 600D75 D65 VeriVide D65 “Artificial Daylight” VeriVide D65 “Artificial Daylight”. Correlated colour temperature 6500K. Within the tolerances

prescribed in BS 950: Part 1; and all international specifications for D65 illluminant. Specified for most applications where there is a need to maintain colour consistency and quality.Conforming highly to the CIE specifications, for accurate colour matching. 98 600mm 1200mm 1500mm 18w 36w 58w T8 T8 T8 600D65 1200D65 1500D65 D50 D50 “Artificial

Daylight” Correlated colour temperature of 5000K. For the Graphic Technology and Photography industries. D50 lamps conform to BS 950: Part 2 and ISO 3664. Recommended for transmitted light source to view transparencies and for the reflected light source to view reproductions. 98 600mm 1200mm 1500mm 18w 36w 58w T8 T8 T8 60095

120095 150095

CIE Illuminant ‘A’ Light Source Name Lamp Description C.R.I. Length Watts Diam Product Code’F’ Tungsten Filament Tungsten Filament Lighting. Approximate color temperature of 2800K. Required by BS 950: Part 1 as a test for metamerism (approximating CIE Illuminant ‘A’). Typical light source used within domestic environments. 100 Globe Globe Round Clear-

284mm Opal-284mm 40w60w 150w 60w 60w 45mm 45mm – 40G450 60G450 150FILO 28460CL28460OP’A’ Tungsten Halogen Tungsten Halogen Lighting (CIE Illuminant ‘A’). This represents incandescent A (inc-A) with a colour temperature of 2856K. Typical light source used within domestic environments. Used to check for metamerism. 100 – 35w – HALO/12V

/35WLP Alternative (fluorescent) lighting / Point of SaleLight Source Name Lamp Description C.R.I. Length Watts Diam Product Code840 P15 VeriVide 840P15 Narrow Band Triphosphor Fluorescent Lamps. Correlated colour tempera ture of 4000K. CIE Illuminant F11. Often chosen as a European “Point of Sale” light source, with good colour rendering and manufactured to a tighter tolerance

specification as prescribed by Marks & Spencer. (Formerly TL84P15) 85 600mm 1200mm 1500mm 18w 36w 58w T8 T8T8 60084P15120084P15 150084P15CWF Cool White Cool White Broad Band Fluorescent Lamps. Correlated colour temperature of 4000K. Used as an American “Point of Sale” light source. Moderate colour rendering. 62 600mm 1200mm 1500mm 20w 40w

65/80w T12 T12 T12 60033 120033 150033U35 Ultralume 35 Ultralume Narrow Band Triphosphor Fluorescent Lamp.Correlated colour temperature 3500K. An American “Point of Sale” light source, with good colour rendering. 86 600mm 1200mm 17w 32w T8 T8 T8 600U35

1200U35 830 830 Narrow Band Triphosphor Fluorescent Lamp. Correlated colour temperature

3000K. Often chosen as a European “Point of Sale” light source with good colour rendering.(Formerly TL83) 85 600mm 1200mm 1500mm 18w 36w 58w T8 T8 T8 60083

120083 150083 Horizon Light Source Name Lamp Description C.R.I. Length Watts Diam Product Code ‘H’ Horizon Lighting Colour temperature 2300K. Used for Automotive, Apparel

and Metamerism Testing. As specified by the ASTM (American Society for testing and Materials) D1729-74, Standard Practise for Visual Evaluation of Colour Differences of Opaque Materials. 98 – 75w – HALO/12V /75WUltraviolet Light Source Name Lamp Description C.R.I. Length Watts Diam Product Code UV Ultraviolet Ultraviolet Blacklight. Used to detect the

presence of Optical Brightening Agents and/or Fluorescent dyes. Therefore it is useful when assessing white and Fluorescent shades to check the level present and its evenness. N/A Clear-450mm Blacklight-600mm 15w 18w T8 T8 450UV15 600UV18 Paint specification of VeriVide Colour Assessment Cabinets

PAINT (For Cabinet Interiors) Name Description Quantity Product Code Crown Plain Grey 5574 Matt Emulsion 0.5 Litre Tins 5574 0.5L Munsell N5 0.5 Litre Tins N5 0.5L Munsell N7 0.5 Litre Tins N7 0.5L VERIVIDE MAINTENANCE PACK The VeriVide Maintenance Pack includes Cleaning Materials, Brush & Roller plus 0.5 litres of Paint.

https://maamtexbd.com/product/verivide-colour-assessment-cabinets/

Related products

Stretch Recovery Tester Static Method

Stretch Recovery Tester Static Method

Stretch Recovery Tester

- A sample is stretched to a predetermined extension or force.

- The stretch is maintained for a set period.

- After removing the load, the recovery (return to original length) is measured after a fixed time.

- The fabric sample is clamped and stretched to a specific length or force.

- It’s held for a fixed duration (e.g., 1–5 minutes).

- The tension is released, and the sample is allowed to recover.

- The recovered length is measured after a set time.

Stretch Recovery Tester

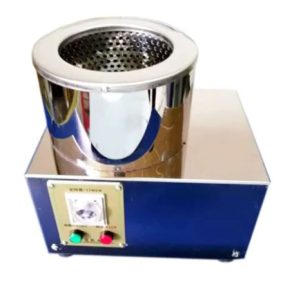

Laboratory mini stenter Dryer

Laboratory mini stenter Dryer

A Laboratory Mini Stenter Dryer is a compact, lab-scale machine designed to simulate the drying and heat-setting processes used in textile finishing. It mimics the function of industrial stenter machines but on a much smaller scale, making it ideal for testing fabric behavior, shrinkage, and finish quality under controlled conditions. Key Features:- Controlled Heating System

- Adjustable Fabric Width

- Variable Speed Conveyor - Allows control over fabric dwell time for drying or heat-setting.

- Compact and Bench-Top Design - Space-saving design ideal for textile labs and R&D units.

- Digital Controls - Easy-to-use digital interface for setting temperature, conveyor speed, and process time.

- Transparent Viewing Window - Allows operators to monitor fabric movement and drying visually.

- Low Energy Consumption - Designed for lab use, consuming less power than industrial models.

- Accurate Simulation of Production - Mimics industrial stenter conditions on a lab scale, ideal for pre-production testing and R&D.

- Cost-Effective Testing - Enables testing and fabric finishing without the high cost or space requirements of full-scale machines.

- Energy Efficient - Consumes less power compared to large stenters, making it economical for small-scale or frequent use.

- Precise Control - Offers accurate control of temperature, speed, and fabric tension, ensuring consistent results.

- Space-Saving Design - Compact and bench-top friendly, perfect for laboratories with limited space.

- Multiple Applications - Useful for drying, heat-setting, shrinkage testing, and evaluating chemical finishes.

- Faster Development Cycles - Speeds up new product development by allowing rapid sample testing and adjustments.

- Improved Fabric Quality - Helps optimize finishing parameters for better dimensional stability, hand feel, and appearance.

- Safe and User-Friendly- Designed with lab safety in mind, including temperature safety controls and easy operation.

- Compact Bench-Top Design - Ideal for laboratory use with limited space requirements.

- Adjustable Temperature Control - Precise heating (usually up to 220–250°C) with digital controllers for accurate processing.

- Variable Conveyor Speed- Allows adjustment of fabric dwell time for different drying or heat-setting needs.

- Width Adjustment Mechanism - Equipped with clips or pins to stretch and fix fabric width-wise, simulating industrial stenter conditions.

- Transparent Viewing Window - Enables visual monitoring of fabric movement and drying inside the chamber.

- Digital Display Panel- Easy-to-use interface for setting and monitoring temperature, speed, and time.

- Stainless Steel Construction- Durable and corrosion-resistant for long-term use at high temperatures.

- Uniform Heat Distribution- Ensures consistent fabric treatment across the width.

- Safety Features- Over-temperature protection and insulated body for operator safety.

- Versatile Applications - Suitable for drying, heat-setting, shrinkage testing, and chemical finish evaluations.

Fabric Stiffness Tester

Fabric Stiffness Tester

Fabric Stiffness Tester is a lab instrument used to measure the stiffness or flexural rigidity of fabric materials. It evaluates how resistant a fabric is to bending, which influences its drape, comfort, and handling characteristics. Purpose of Fabric Stiffness Tester: To determine the stiffness of textiles by measuring the bending length and calculating flexural rigidity, often using methods like the Cantilever Test (as per ASTM D1388 or ISO 9073-7). Working Principle of Fabric Stiffness Tester: A fabric strip is slid over a horizontal platform until its free end bends under its own weight to a specific angle (usually 41.5°). The length at which this occurs is used to calculate bending length and stiffness. Main Components of Fabric Stiffness Tester: - Test Platform: Flat surface for sample movement. - Graduated Scale: Measures the overhanging length of fabric. - Angle Indicator: Guides the measurement based on standard deflection angle. - Fabric Clamp or Guide: Helps place and move the sample smoothly. Applications of Fabric Stiffness Tester: - Apparel fabrics (e.g., for comfort and drape analysis) - Technical textiles (e.g., automotive, medical fabrics) - Paper, nonwovens, and films Benefits of Fabric Stiffness Tester:- Accurate Measurement of Flexibility - Provides reliable data on fabric stiffness, essential for quality control and product development.

- Improves Product Comfort - Helps assess how soft or rigid a fabric will feel in clothing or furnishings.

- Supports Material Selection - Aids designers and engineers in choosing the right fabric for specific applications based on stiffness.

- Quality Assurance - Detects fabric inconsistencies or defects that affect handling or drape.

- Standards Compliance - Enables testing as per international standards like ASTM D1388 and ISO 9073-7 for global product approval.

- Quick and Simple Operation - Delivers fast results with minimal operator training or preparation.

- Applicable to Multiple Materials - Suitable for woven, nonwoven, knitted fabrics, paper, and films.

- Enhances R&D Accuracy - Supports consistent material testing during product innovation and textile finishing.

- Graduated Measurement Scale - Precise scale to measure overhang length for accurate stiffness calculation.

- Flat Test Platform - Smooth, level surface ensures consistent and reliable fabric movement.

- Standard Deflection Angle Guide - Built-in 41.5° angle reference for consistent stiffness testing (per ASTM/ISO).

- Manual or Motorized Models - Available in both types for simple or automated operation depending on lab needs.

- Compact Design - Space-saving unit ideal for textile labs and quality control rooms.

- Sample Holder or Clamp - Ensures correct alignment and smooth feeding of fabric strips during testing.

- Durable Construction - Made of corrosion-resistant materials like stainless steel or aluminum for long-term use.

- Compliance with Standards - Supports methods like ASTM D1388, ISO 9073-7 for stiffness testing of fabrics.

- Lightweight and Portable - Easy to move and use in various lab settings.

- Low Maintenance - Simple mechanical parts require minimal servicing.

- Prepare the Sample - Cut the fabric into a rectangular strip (e.g., 25 mm × 200 mm), as per standard.

- Place the Sample - Lay the fabric strip flat on the test platform with one end aligned at the zero mark.

- Slide the Fabric - Gently push the fabric forward so it slowly overhangs the platform.

- Watch for Deflection - Stop sliding when the free end of the fabric bends down to the reference angle (typically 41.5°).

- Read the Bending Length - Measure the overhang distance from the scale. This is the bending length (C).

- Calculate Flexural Rigidity

- Repeat for Accuracy - Test both warp and weft directions and average the results for better accuracy.

Scope of application

It is used to measure the stiffness of cotton,

wool, silk, linen, chemical fibers and other woven fabrics,

knitted fabrics, general nonwovens, coated fabrics, etc.

It is also suitable for measuring the stiffness of paper,

leather, film and other flexible materials.

Relevant Standards

GB/T 18318, ASTM D 1388, IS09073-7, BS EN22313 etc.

[Instrument Characteristics]

1. Infrared photoelectric invisible inclined plane

detection system replaces the traditional tangible inclined plane,

realizes non-contact detection, and overcomes the problem that

the measurement accuracy is affected by

the sample torsion lifted by the inclined plane.

2. The inclination adjustable mechanism of instrument

measurement to meet different test requirements.

3. Stepping motor drive, accurate measurement, smooth operation;

4. The color touch screen display can show the extended length,

bending length, bending stiffness of the sample, the warp average,

the weft average and the total average of the above values respectively.

5. Printing of Chinese report forms for thermal printers.

Technical parameters

1. Test methods: The two method (A method: Weft test, B method: Forward and backward test)

2. Measurement angle:41.5 degree, 43 degree and 45 degree adjustable

3. Extend the length range:5-220 mm (special requirements can be made at the time of ordering)

4. Length resolution:0.01mm

5. Measurement accuracy:±0.1mm

6. Specimen specifications:250×25mm

7. Work platform specifications:250×50mm

8. Specification of sample pressing plate:250×25mm

9. Pushing speed of press plate:3 mm/s; 4 mm/s; 5 mm/s

10. Display output: Touch screen display

11. Print Output: Chinese Report

12. Data Processing Volume: A total of 15 groups, each group less than 20 trials

13. Printer: Thermal printer

14, power supply:AC220V 50Hz

15. Host volume:570mm×360mm×490mm

16. Host weight:20kg

Scope of application

It is used to measure the stiffness of cotton,

wool, silk, linen, chemical fibers and other woven fabrics,

knitted fabrics, general nonwovens, coated fabrics, etc.

It is also suitable for measuring the stiffness of paper,

leather, film and other flexible materials.

Relevant Standards

GB/T 18318, ASTM D 1388, IS09073-7, BS EN22313 etc.

[Instrument Characteristics]

1. Infrared photoelectric invisible inclined plane

detection system replaces the traditional tangible inclined plane,

realizes non-contact detection, and overcomes the problem that

the measurement accuracy is affected by

the sample torsion lifted by the inclined plane.

2. The inclination adjustable mechanism of instrument

measurement to meet different test requirements.

3. Stepping motor drive, accurate measurement, smooth operation;

4. The color touch screen display can show the extended length,

bending length, bending stiffness of the sample, the warp average,

the weft average and the total average of the above values respectively.

5. Printing of Chinese report forms for thermal printers.

Technical parameters

1. Test methods: The two method (A method: Weft test, B method: Forward and backward test)

2. Measurement angle:41.5 degree, 43 degree and 45 degree adjustable

3. Extend the length range:5-220 mm (special requirements can be made at the time of ordering)

4. Length resolution:0.01mm

5. Measurement accuracy:±0.1mm

6. Specimen specifications:250×25mm

7. Work platform specifications:250×50mm

8. Specification of sample pressing plate:250×25mm

9. Pushing speed of press plate:3 mm/s; 4 mm/s; 5 mm/s

10. Display output: Touch screen display

11. Print Output: Chinese Report

12. Data Processing Volume: A total of 15 groups, each group less than 20 trials

13. Printer: Thermal printer

14, power supply:AC220V 50Hz

15. Host volume:570mm×360mm×490mm

16. Host weight:20kg Fabric air permeability tester

Fabric Air Permeability Tester

Fabric Air Permeability Tester is a lab instrument used to measure how easily air passes through a fabric. It quantifies the air permeability, which is crucial for evaluating breathability, comfort, and functional performance in textiles. Purpose Fabric Air Permeability Tester: It determines the rate of airflow through a fabric sample under a set air pressure, typically reported in units like cm³/cm²/s or L/m²/s. Working Principle: The tester creates a pressure difference across the fabric sample and measures the volume of air flowing through it. Higher air permeability means the fabric is more breathable. Main Components of Fabric Air Permeability Tester: - Test Head / Clamp: Holds the fabric securely without leakage. - Pressure Regulator: Maintains a constant air pressure during testing. - Flow Meter or Digital Sensor: Measures the actual airflow rate through the fabric. - Display Unit: Shows readings of air permeability instantly. Applications of Fabric Air Permeability Tester: - Performance textiles (sportswear, PPE) - Technical fabrics (filters, tents, airbags) - Medical textiles (masks, gowns) - Nonwovens and industrial materials Benefits of Fabric Air Permeability Tester:- Accurate Breathability Measurement - Precisely measures how breathable a fabric is, essential for comfort and performance.

- Supports Quality Control - Ensures consistent air permeability in fabric batches, critical for products like PPE, sportswear, and filters.

- Enhances Product Design - Helps in selecting or engineering fabrics with the right airflow properties for specific uses.

- Standard Compliance - Conforms to international testing standards (e.g., ASTM D737, ISO 9237), ensuring global credibility.

- Quick and Reliable Testing - Provides rapid results, increasing lab efficiency and production decision-making speed.

- Wide Material Compatibility - Suitable for woven, nonwoven, knitted fabrics, and even paper or coated materials.

- Improves Functional Performance - Helps optimize products for ventilation, moisture control, and thermal comfort.

- Reduces Product Failure - Identifies underperforming fabrics early, minimizing risks in high-performance applications.

- Digital Display - Shows air permeability readings clearly in units like L/m²/s or cm³/cm²/s.

- Precise Test Head/Clamp - Provides an airtight seal to prevent air leakage and ensure accurate results.

- Adjustable Pressure Settings - Allows testing under various pressure drops (e.g., 10–2500 Pa), depending on fabric type.

- Automatic Airflow Measurement - Built-in sensors or flow meters capture airflow rate automatically for quick analysis.

- Multiple Test Area Sizes - Interchangeable test plates to match different sample sizes and standard requirements.

- Data Logging and Export - Some models include USB or software connectivity for storing and exporting test results.

- Standard Compliance - Conforms to ASTM D737, ISO 9237, BS 5636, DIN 53887, etc.

- Robust Construction - Built with corrosion-resistant materials and durable components for long-term lab use.

- Low Maintenance - Simple cleaning and calibration process for reliable performance.

- Compact and User-Friendly Design - Ideal for lab benches and easy operation with minimal training.

- Prepare the Sample - Cut the fabric sample to the required size (usually circular, e.g., 20 cm²).

- Mount the Sample - Place the fabric securely in the test clamp or holder, ensuring no wrinkles or gaps.

- Set Test Parameters - Adjust the air pressure drop according to the fabric type or standard (e.g., 100 Pa).

- Start the Test - Turn on the air supply and start the airflow through the fabric.

- Read the Measurement - The digital display will show the air permeability value in the selected units.

- Record the Results - Note the readings or export data if the device supports it.

- Repeat if needed - Test multiple samples or areas for accuracy and average the results.

- Clean and Maintain - After testing, clean the clamp and ensure the device is calibrated regularly.

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm IR Dyeing Machine Dunlin

IR Dyeing Machine Dunlin

IR Dyeing machine Dunlin is Safe, high efficiency, environment friendly, energy saving, optimum for new dyeing small sample machines0 - 3.5 ℃ / min Cooling rate 0.2 - 5 ℃ / min Cooling method Air-cooled Rotation speed 0 - 60 rpm Liquor ratio 1:5 -1:100 Power supply 1∮AC 220V 50/60HZ Dimensions( L x W x H) 670×670×780mm 860×680×780mm Weight 100kg 120kg Standard Accessories Cups 1set

Put the test sample. Cups stand 1set Place where to put cups. Protective glove 1set To avoid to be hurt by HT cups. Model: IF-24SCapacity: 24 pots Brad: DUNLIN Origin: China

Color dyeing tests for various dyestuffs of IR Dyeing machine Dunlin- Step dyeing tests. C. Dispersing, levelling and impregnating test. D. High or low liquor ratio exhausting tests. E. Fabric steak and staining tests. F. Concentration tests and others. Protection and Safety gates to protect. Temperature control accuracy +/- 0.2degree

IR Dyeing machine

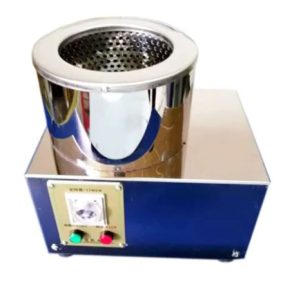

Laboratory hydro Extractor

Laboratory Hydro Extractor

A Laboratory Hydro Extractor is a compact, high-speed centrifuge used in textile labs to remove excess water from fabric or yarn samples after dyeing or washing. It works on the principle of centrifugal force, efficiently reducing moisture content before drying. Key Features:- Centrifugal Water Extraction - Uses high-speed spinning (typically 1400–2800 RPM) to extract water from textiles.

- Stainless Steel Inner Basket - Perforated drum holds fabric/yarn securely and allows water to drain efficiently.

- Compact Lab Design - Space-saving unit designed specifically for laboratory sample sizes.

- Digital Timer and Speed Control - Allows precise setting of spin duration and RPM to match sample needs.

- Safety Lock System - Ensures the lid remains closed during operation for user safety.

- Quick Water Removal - Significantly reduces drying time by extracting up to 90–95% of water content.

- Low Noise and Vibration - Balanced design ensures quiet and stable operation.

- Efficient Water Removal - Rapidly extracts 90–95% of water from samples, reducing drying time significantly.

- Saves Time and Energy - Cuts down the load on dryers and shortens total processing time in lab workflows.

- Improves Sample Quality - Gentle spinning preserves fabric structure, avoiding damage or distortion.

- Precise Control - Adjustable speed and timer ensure optimal settings for different fabric types.

- Compact and Lab-Friendly - Small footprint ideal for laboratory use with limited space.

- User Safety - Safety lock prevents lid opening during operation, protecting the user.

- Cost-Effective - Reduces the need for extended dryer use, saving on electricity and equipment wear.

- Versatile Use - Suitable for yarn, fabric, and garment samples across various fiber types.

- High-Speed Centrifugal Operation - Typically runs at 1400–2800 RPM for quick and efficient water removal.

- Stainless Steel Inner Drum - Corrosion-resistant, perforated basket for durability and efficient water drainage.

- Digital Timer and Speed Control - Allows precise control of spin duration and speed based on sample type.

- Compact and Portable Design - Ideal for lab environments with limited space.

- Safety Lock Mechanism - Prevents the lid from opening while the machine is in operation.

- Shock Absorption System- Reduces vibration and noise for smooth, stable performance.

- Quick Cycle Times - Short dewatering cycles improve lab throughput and efficiency.

- Low Maintenance Design - Simple mechanical setup with easy-to-clean components.

- Sample Versatility - Suitable for small fabric swatches, yarns, and small garments.

- Energy Efficient - Uses minimal power while delivering high performance.

- Prepare the Sample - After dyeing or washing, gently squeeze excess water from the fabric or yarn sample by hand.

- Load the Sample - Open the lid and place the sample evenly in the stainless steel drum. - Avoid overloading or uneven placement to maintain balance.

- Close the Lid securely - Ensure the safety lid is properly closed and locked.

- Set the Timer and Speed - Use the control panel to set the spin time (typically 1–5 minutes) and RPM suitable for the sample type.

- Start the Machine- Press the start button. The extractor will spin at the selected speed to remove water via centrifugal force.

- Wait for Spin Completion - The machine will automatically stop after the timer runs out.

- Unload the Sample - Once the drum stops completely, open the lid and carefully remove the sample.

- Proceed to Drying - The dewatered sample can now be air-dried or placed in a drying oven or stenter.

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Laboratory hydro Extractor Machine Dunlin price in Bangladesh Laboratory hydro Extractor Machine Dunlin in textile Textile testing equipment in Bangladesh Textile testing equipment in Dhaka Textile testing equipment in Uttara MAAM tex Laboratory hydro Extractor Machine Dunlin price in Bangladesh

Laboratory hydro ExtractorDigital Bench top PH Meter

Digital Bench top PH Meter

Digital Bench top PH Meter

Brand: Hanna Model: HI2002 Country of Manufacture: Romania Origin: USA

Digital Bench top PH Meter

Single parameter of Digital Bench top PH Meter features user-friendly tablet design with bench, portable or wall mount options for ultimate flexibility. Switch from portable to bench in the same procedure or clear the surface for easier working and hang on the wall. Digital Bench top PH Meter Range -2.00 to 16.00pH; pH Digital smart electrode compatible Accuracy: ±0.01 pH edge® pH is dedicated to testing pH. Using Hanna's latest innovation in technology and design, edge® can be adapted to suit your working method. Select from hand held, wall mount or bench top - or switch between them all. edge® is happy any which way. Simply plug in the electrode, then play. Measurement is simpler, quicker and more accurate than ever. Results are fast and reliable. Combining high precision technology with the user-friendly dimensions and format of a small digital tablet, edge® is breaking new ground in electrochemistry. This is a must-have meter for your laboratory.| pH Range | basic mode: -2.00 to 16.00 pH; standard mode: -2.000 to 16.000 pH | |

| Resolution | basic mode: 0.01 pH; standard mode: 0.001 pH | |

| Accuracy (@25°C) | basic mode: ±0.01 pH; standard mode: ±0.002 pH | |

| Calibration | basic mode: automatic, up to three points calibration, 5 standard buffers available; standard mode: automatic, up to five point calibration, 7 standard buffers available and two custom buffers | |

| Temperature Compensation | automatic, -5.0 to 100.0°C (using integral temperature sensor) | |

| Electrode Diagnostics | standard mode: probe condition, response time and out of calibration range | |

| mV pH Range | ±1000 mV | |

| Resolution | 0.1 mV | |

| Accuracy (@25°C) | ±0.2 mV | |

| ORP Range | ±2000 mV | |

| Resolution | 0.1 mV | |

| Accuracy (@25°C) | ±0.2 mV | |

| Temperature Range | -20.0 to 120.0°C | |

| Resolution | 0.1°C | |

| Accuracy | ±0.5°C | |

| Additional Specifications: | ||

| Probe | HI-11310 digital glass body pH electrode with 3.5mm connector and 1m cable | |

| Logging | up to 1000 (400 for basic mode) records organised in: manual log-on demand (max. 200 logs), manual log-on-stability (max. 200 logs), interval logging (max. 600 samples; 100 lots) | |

| Connectivity | 1 USB port for storage; 1 micro USB port for charging and PC connectivity | |

| Environment | 0 to 50°C; RH max 95% non-condensing | |

| Power Supply | 5 VDC adapter (included) | |

| Dimensions | 2020 x 140 x 12 mm | |

| Weight | 250 g |

- High Accuracy and Resolution

- Digital Display - Large, clear LCD or LED screen shows pH readings, temperature, and sometimes mV or ion concentration. - Some models include a backlit display for better visibility.

- Electrode System - Uses a pH-sensitive electrode (usually glass) connected to a reference electrode. Electrodes are often replaceable and require regular calibration and maintenance.

- Temperature Compensation - Automatic or manual temperature compensation to correct pH readings based on sample temperature. - Integrated temperature sensors or separate probes are used.

- Calibration Functions - Supports 2-point, 3-point, or multi-point calibration using standard buffer solutions. - Auto-recognition of calibration buffers in advanced models.

- Data Storage and Connectivity - Internal memory for storing results. - USB or RS232 ports for data export to PCs or printers; some models support wireless connectivity.

- Sturdy Design - Benchtop models are larger and more stable than portable meters. - Often come with a durable casing and electrode arm for hands-free operation.

- High Accuracy and Precision

- User-Friendly Interface- Digital displays (LCD/LED) make readings easy to see and interpret.- Many models offer intuitive controls and guided calibration, simplifying operation.

- Advanced Calibration Features- Supports multi-point calibration for improved accuracy across a wide pH range.- Some models automatically recognize buffer solutions, reducing user error.

- Temperature Compensation- Automatic temperature compensation (ATC) corrects readings based on sample temperature, ensuring accuracy.

- Stable and Durable Design- Benchtop units are more robust and stable than handheld devices, reducing the risk of spills or tipping.- Often include electrode holders or arms for secure, hands-free measurements.

- Data Management and Connectivity- Built-in memory for storing measurement data.USB, RS232, or wireless connectivity for exporting data to computers or laboratory information systems (LIS).

- Multi-Functionality- Some models also measure ORP (oxidation-reduction potential), ion concentration, or conductivity.- Suitable for a variety of testing needs beyond just pH.

- Ideal for Long-Term Use- Designed for prolonged and repeated use in laboratory environments.- Replaceable electrodes and parts extend the meter’s usable life.

- Compliance and Documentation- Data logging features support documentation and compliance with regulatory standards in regulated industries (e.g., pharma, food, environmental testing).

Bursting strength tester

Bursting strength tester

true burst

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

- Bursting pressure can reach up to 1.2MPa 5. The maximum burst and expansion degree can reach 70mm. 6. Strengthen the lighting system on the test surface. 7. The main aerodynamic force helps to clamp the sample system. 8. A variety of test areas are available, and the switching is easy.

- A variety of unit conversions between Chinese and English. 10. Reliable anti-pinch safety protection design. [Technical parameter]: 1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized) 2. The minimum graduation value: 0.0001Mpa 3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree pressurization.

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated