Rainin Digital Pipette

$0.00

Rainin Digital Pipette

Digital Pipette

Rainin Digital Pipette E4-XLS Electronic Pipette,

The Rainin Digital Pipette is a high-precision liquid handling instrument used in laboratories for accurate and reproducible measurement and transfer of small liquid volumes. Manufactured by Rainin Instruments (a Mettler Toledo company), these pipettes are known for their ergonomic design, reliability, and advanced digital controls.

Features of Rainin Digital Pipette:

- Digital Volume Setting

– Allows for precise and repeatable volume adjustments via a digital display or dial.

– Reduces user error compared to manual pipettes.

- High Accuracy and Precision

– Offers minimal variability in volume delivery, making it ideal for sensitive assays and experiments.

- Ergonomic Design

– Lightweight and comfortable to use over long periods, reducing hand strain (good for repetitive tasks). – Often features a finger hook and low pipetting force.

- Easy Calibration and Maintenance

– Includes software or manual options for calibration.

– Designed for easy disassembly and cleaning.

- Durable and Chemically Resistant – Built with high-quality materials that resist damage from chemicals and frequent use.

- Models and Volume Ranges – Available in single-channel and multi-channel versions.

Covers a wide volume range from 0.1 µL to 10 mL depending on the model.

- LTS (LiteTouch System) – Many Rainin pipettes use the LTS tip system which reduces tip ejection force and ensures a consistent seal.

- Compliance and Traceability – Some digital models offer data storage or integration with lab information systems for traceability.

Applications

– Molecular biology

– Microbiology

– Clinical diagnostics

– Pharmaceutical and chemical research

Benefits of Rainin Digital Pipette:

- High Accuracy and Precision – Ensures reliable and reproducible results, essential for sensitive experiments.

- Digital Volume Control – Reduces human error with easy and precise volume setting via digital interface.

- Ergonomic Design- Minimizes hand strain and fatigue during prolonged use; ideal for repetitive pipetting tasks.

- LiteTouch System (LTS) – Eases tip attachment and ejection, reducing risk of RSI (Repetitive Strain Injury) and improving comfort.

- Versatile Volume Range – Available in multiple models to handle volumes from microliters to milliliters.

- Durable and Reliable – Built with high-quality materials for long life and resistance to chemicals and frequent use.

- Easy Maintenance and Calibration – Simplified calibration and cleaning ensure long-term performance and compliance.

- Data Integrity and Traceability -Some models store data, supporting audit trails and regulatory compliance.

- Enhanced Productivity – Quick setup, easy operation, and consistent performance speed up lab workflows.

Features of Rainin Digital Pipette:

- Digital Volume Adjustment – Precise and easy-to-read digital display for accurate volume setting.

- High Precision and Accuracy- Delivers consistent results, meeting ISO and GLP/GMP standards.

- Ergonomic Design- Lightweight, balanced with low plunger and tip ejection force to reduce fatigue.

- LiteTouch Tip Ejection System (LTS) – Reduces tip attachment/ejection force, improving comfort and consistency.

- Durable Construction – Built with high-quality, chemically resistant materials for long-term use.

- Wide Volume Range – Available in multiple models from 0.1 µL to 10 mL.

- Single-Channel and Multi-Channel Options – Suitable for various applications including high-throughput assays.

- Autoclavable Components- Some parts can be autoclaved for sterilization and contamination control.

- Easy Calibration and Maintenance – User-friendly calibration settings with accessible parts for cleaning.

- Optional Electronic Models – Some versions include programmable features, multiple modes (e.g., reverse pipetting), and memory storage.

Rainin Digital Pipette dealer In Bangladesh,

Digital Pipette Importer in Bangladesh,

Digital Pipette in Bangladesh,

Digital Pipette Machine in Bd,

Digital Pipette In Uttara,

Digital Pipette Price in Bangladesh,

Digital Pipette Supplier in Bangladesh,

Digital Pipette in Bangladesh,

Related products

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

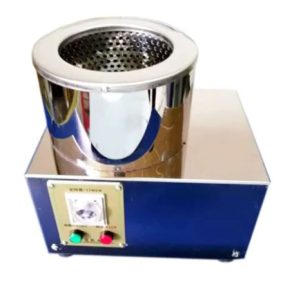

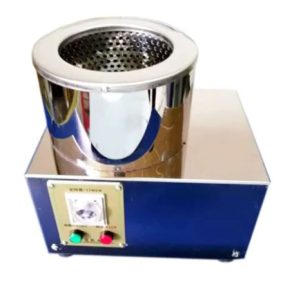

Laboratory hydro Extractor

Laboratory Hydro Extractor

A Laboratory Hydro Extractor is a compact, high-speed centrifuge used in textile labs to remove excess water from fabric or yarn samples after dyeing or washing. It works on the principle of centrifugal force, efficiently reducing moisture content before drying. Key Features:- Centrifugal Water Extraction - Uses high-speed spinning (typically 1400–2800 RPM) to extract water from textiles.

- Stainless Steel Inner Basket - Perforated drum holds fabric/yarn securely and allows water to drain efficiently.

- Compact Lab Design - Space-saving unit designed specifically for laboratory sample sizes.

- Digital Timer and Speed Control - Allows precise setting of spin duration and RPM to match sample needs.

- Safety Lock System - Ensures the lid remains closed during operation for user safety.

- Quick Water Removal - Significantly reduces drying time by extracting up to 90–95% of water content.

- Low Noise and Vibration - Balanced design ensures quiet and stable operation.

- Efficient Water Removal - Rapidly extracts 90–95% of water from samples, reducing drying time significantly.

- Saves Time and Energy - Cuts down the load on dryers and shortens total processing time in lab workflows.

- Improves Sample Quality - Gentle spinning preserves fabric structure, avoiding damage or distortion.

- Precise Control - Adjustable speed and timer ensure optimal settings for different fabric types.

- Compact and Lab-Friendly - Small footprint ideal for laboratory use with limited space.

- User Safety - Safety lock prevents lid opening during operation, protecting the user.

- Cost-Effective - Reduces the need for extended dryer use, saving on electricity and equipment wear.

- Versatile Use - Suitable for yarn, fabric, and garment samples across various fiber types.

- High-Speed Centrifugal Operation - Typically runs at 1400–2800 RPM for quick and efficient water removal.

- Stainless Steel Inner Drum - Corrosion-resistant, perforated basket for durability and efficient water drainage.

- Digital Timer and Speed Control - Allows precise control of spin duration and speed based on sample type.

- Compact and Portable Design - Ideal for lab environments with limited space.

- Safety Lock Mechanism - Prevents the lid from opening while the machine is in operation.

- Shock Absorption System- Reduces vibration and noise for smooth, stable performance.

- Quick Cycle Times - Short dewatering cycles improve lab throughput and efficiency.

- Low Maintenance Design - Simple mechanical setup with easy-to-clean components.

- Sample Versatility - Suitable for small fabric swatches, yarns, and small garments.

- Energy Efficient - Uses minimal power while delivering high performance.

- Prepare the Sample - After dyeing or washing, gently squeeze excess water from the fabric or yarn sample by hand.

- Load the Sample - Open the lid and place the sample evenly in the stainless steel drum. - Avoid overloading or uneven placement to maintain balance.

- Close the Lid securely - Ensure the safety lid is properly closed and locked.

- Set the Timer and Speed - Use the control panel to set the spin time (typically 1–5 minutes) and RPM suitable for the sample type.

- Start the Machine- Press the start button. The extractor will spin at the selected speed to remove water via centrifugal force.

- Wait for Spin Completion - The machine will automatically stop after the timer runs out.

- Unload the Sample - Once the drum stops completely, open the lid and carefully remove the sample.

- Proceed to Drying - The dewatered sample can now be air-dried or placed in a drying oven or stenter.

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Laboratory hydro Extractor Machine Dunlin price in Bangladesh Laboratory hydro Extractor Machine Dunlin in textile Textile testing equipment in Bangladesh Textile testing equipment in Dhaka Textile testing equipment in Uttara MAAM tex Laboratory hydro Extractor Machine Dunlin price in Bangladesh

Laboratory hydro ExtractorPerspiration Tester

Perspiration Tester

Perspiration Tester

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Stainless Steel Frame - Corrosion-resistant body for durability and long-term use.

- Multi-Sample Capacity - Can hold up to 20 or more specimens for batch testing.

- Standardized Loading Weight- Applies uniform pressure (usually 12.5 kPa) across all samples.

- Removable Plates - Glass or acrylic plates ensure even contact and easy cleaning.

- Compact Design- Space-saving, bench-top model ideal for lab environments.

- Complies with Test Standards - Meets ISO 105 E04, AATCC 15, and related perspiration fastness standards.

- Ease of Operation - Simple loading, unloading, and incubation process.

- High-Temperature Resistance - Can be used inside incubators at 37°C or ovens as required.

- Prepare the Test Solution - Mix artificial acidic or alkaline perspiration as per standard (ISO or AATCC).

- Cut the Fabric Samples - Cut both the test fabric and adjacent white fabric (usually cotton) to standard size.

- Soak the Samples - Immerse the fabric sandwich (test + adjacent) in the test solution for 30 minutes.

- Remove Excess Liquid - Gently squeeze or blot to remove extra moisture—do not dry.

- Load in the Tester- Place each sandwich between glass or acrylic separator plates in the tester.

- Apply Pressure - Tighten the top plate or place the standard weight on top to apply uniform pressure.

- Incubate - Keep the loaded tester in an oven or incubator at 37°C for 4–16 hours (depending on the method).

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Dry and Evaluate - Remove, air dry the samples, then assess color change and staining using a gray scale.

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

Perspiration Tester

HTHP Glycerin bath dyeing machine

HTHP Glycerin Bath Dyeing Machine

HTHP dyeing machine

- High Temperature Capability - Operates up to 140°C or more, ideal for disperse dyeing of polyester which requires elevated temperatures.

- Glycerin as Heat Transfer Medium - Glycerin allows for precise and uniform heating beyond the boiling point of water, without pressure buildup as in steam-based systems.

- Small Sample Dyeing - Used for lab-scale dyeing of fabric or yarn samples (commonly 5–10 g per tube), useful in R&D or color matching.

- Multiple Sample Capacity - Usually has multiple dyeing tubes/chambers for simultaneous dyeing of several samples under identical conditions.

- Accurate Temperature and Time Control - Digital or microprocessor-based controllers regulate temperature, heating rate, and timing precisely.

- Uniform Dyeing - Ensures even dye penetration due to consistent heat distribution and controlled rotation or agitation.

- Energy Efficient Glycerin’s heat retention reduces energy consumption compared to steam systems.

- Compact and Durable Design - Bench-top design, made from stainless steel and heat-resistant components for long life and lab use.

- Uniform Heating with Glycerin - Glycerin provides consistent heat transfer, ensuring even dye uptake and minimizing shade variation.

- Energy Efficient- Glycerin retains heat longer, reducing energy consumption compared to traditional steam-based dyeing.

- Accurate Process Control - Precise temperature and time control enhance reproducibility and dyeing consistency.

- Ideal for Lab and Sample Work - Perfect for R&D, shade matching, and recipe development with small fabric or yarn samples.

- Multi-Sample Dyeing - Allows multiple samples to be dyed simultaneously under identical conditions, saving time and effort.

- Compact and Safe - Bench-top design fits in laboratories and is safer than high-pressure steam systems.

- Low Maintenance - Simplified operation and fewer mechanical parts compared to steam-based systems lower upkeep needs.

- Faster Dyeing Cycles- Glycerin heats and cools quickly, reducing overall dyeing time.

- High-Temperature Operation - Capable of dyeing up to 140–150°C, suitable for synthetic fibers like polyester.

- Glycerin as Heat Medium - Uses glycerin for uniform, efficient heat transfer without generating high steam pressure.

- Multiple Dyeing Chambers - Usually equipped with 6–24 tubes for simultaneous multi-sample dyeing under identical conditions.

- Digital Temperature Controller- Offers precise control of temperature, time, and heating rate with programmable settings.

- Compact and Lab-Friendly Design - Bench-top model, easy to operate in laboratory environments with limited space.

- Stainless Steel Construction - Corrosion-resistant and durable for long-term, high-temperature operation.

- Safety Features - Includes over-temperature protection and thermal insulation to prevent heat loss and ensure operator safety.

- Agitation or Sample Rotation- Some models offer rotation or agitation for uniform dye penetration.

- Energy Efficient Heating - Glycerin’s heat retention improves energy efficiency over water- or steam-based systems.

- Low Maintenance - Simplified mechanical system reduces the need for frequent servicing.

Orbital Shaker Machine

Orbital Shaker Machine

Orbital Shaker Machine

- Orbital Motion - Provides a smooth circular shaking pattern, ideal for gentle mixing without foaming or splashing.

- Adjustable Speed Control - Speed typically ranges from 50 to 300 RPM, depending on the model and application.

- Timer Function - Allows users to set shaking time from minutes to hours for precise control of experiments.

- Platform with Clamps or Mats - Holds flasks, beakers, test tubes, or trays securely during operation.

- Digital Display (in advanced models) - Shows speed and time settings for accurate and repeatable performance.

- Variable Capacity - Available in sizes to accommodate different lab needs—from a few samples to dozens.

- Quiet Operation - Designed for minimal vibration and noise during continuous use.

- Uniform Mixing - Ensures even distribution of dyes, chemicals, or cultures without manual stirring.

- Gentle Agitation - Ideal for delicate samples like cell cultures or fabric swatches, reducing damage or splashing.

- Hands-Free Operation - Allows continuous, unattended mixing—improving lab efficiency and freeing up personnel.

- Customizable Settings - Adjustable speed and timer let users tailor mixing to specific sample types and needs.

- Versatile Use - Suitable for a wide range of applications including dye mixing, sample incubation, chemical reaction enhancement, and microbial growth.

- Enhanced Reproducibility - Consistent shaking patterns and digital controls ensure repeatable results across experiments.

- Reduces Human Error - Automated operation minimizes variability and manual handling mistakes.

- Compact and Lab-Friendly - Takes up minimal space while accommodating multiple sample containers.

- Orbital Shaking Motion - Moves samples in a circular path for uniform and consistent mixing.

- Variable Speed Control - Adjustable shaking speed (typically 50–300 RPM) to suit different sample types.

- Digital Timer - Programmable run time for precise and repeatable operations.

- Flat Platform Design - Accommodates flasks, beakers, tubes, or trays with optional clamps or non-slip mats.

- LCD or LED Display (in advanced models) - Shows speed, time, and operating status clearly.

- Quiet Operation - Low-noise motor and stable base minimize vibration and disturbance in the lab.

- Overload Protection - Prevents motor damage from excessive weight or resistance.

- Compact and Durable Build - Designed to fit standard lab benches and withstand regular use.

- Versatile Capacity Options - Available in various sizes to handle different numbers and sizes of containers. User-Friendly Interface - Simple control panel for easy setup and operation.

Brand: Dunlin

Origin: Korea.

Maximum. load capacity (with platform) is 7.5kg

Support orbital and linear shaking

Fashion design of high strength tempered glass on the front panel

LED display for easy-reading of speed and time simultaneously

Digital speed control system and micro-computer control make stable running and prevent sample splashing.

Brushless DC motor is maintenance-free and provides long service life

Over-load and over-speed detection and protection

Supports both orbital shaking and linear shaking and easy to switch the shaking mode

Continuous operation and timed operation in range of 0-99h59min are available

Automatic alarm by time controller allows for unsupervised operation

A wide choice of platforms for various applications

Orbital Shaker Machine Shaker Machine Dunlin price in Bangladesh

Orbital Shaker Machine Shaker Machine Dunlin in textile

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Shaker Machine Dunlin price in Bangladesh

Brand: Dunlin

Origin: Korea.

Maximum. load capacity (with platform) is 7.5kg

Support orbital and linear shaking

Fashion design of high strength tempered glass on the front panel

LED display for easy-reading of speed and time simultaneously

Digital speed control system and micro-computer control make stable running and prevent sample splashing.

Brushless DC motor is maintenance-free and provides long service life

Over-load and over-speed detection and protection

Supports both orbital shaking and linear shaking and easy to switch the shaking mode

Continuous operation and timed operation in range of 0-99h59min are available

Automatic alarm by time controller allows for unsupervised operation

A wide choice of platforms for various applications

Orbital Shaker Machine Shaker Machine Dunlin price in Bangladesh

Orbital Shaker Machine Shaker Machine Dunlin in textile

Textile testing equipment in Bangladesh

Textile testing equipment in Dhaka

Textile testing equipment in Uttara

MAAM tex Shaker Machine Dunlin price in Bangladesh Hydraulic GSM Cutter

Hydraulic GSM Cutter

Hydraulic GSM Cutter

- High Cutting Precision - Ensures consistent and accurate fabric sample size for reliable GSM results.

- Effortless Operation- Hydraulic action reduces manual effort and operator fatigue.

- Ideal for Thick or Multi-Layer Fabrics - Cuts through dense or multiple fabric layers cleanly.

- Time-Saving - Speeds up the sample preparation process, especially for high-volume testing.

- Improves Test Accuracy - Uniform samples help eliminate errors in GSM calculation.

- Durable and Long-Lasting - Robust construction ensures stability and extended service life.

- Safety Enhancement - Reduces risk of injury compared to manual rotary cutters.

- Consistent Pressure Application - Hydraulic mechanism maintains steady force for each cut.

- Hydraulic Press Mechanism - Applies consistent and strong pressure for clean, even cuts.

- Standard Cutting Die (100 cm²) - Produces fabric samples suitable for GSM testing with standard area.

- Heavy-Duty Construction - Built with robust metal frame for long-term lab or industrial use.

- Sharp Stainless Steel Blades - Durable and replaceable blades ensure smooth, precise cuts.

- Cutting Pad Included - Comes with a rubber or nylon base to protect blades and ensure clean edges.

- Simple Lever or Button Operation - Easy to use with minimal training required.

- Non-slip Base - Provides stability during operation for safe, accurate cutting.

- Supports Various Fabric Types

- Place the Cutting Pad - Lay the rubber or nylon cutting pad on a flat surface.

- Position the Fabric - Place the fabric sample flat and smooth on the cutting pad.

- Align the Cutter - Position the GSM cutter die over the desired area of the fabric.

- Activate Hydraulic Press - Pull the lever or press the button to apply hydraulic pressure and cut the sample.

- Remove the Sample - Lift the cutter and carefully take out the circular fabric piece (usually 100 cm²).

- Weigh the Sample - Place the cut sample on a precision balance or GSM scale to determine weight.

- Calculate GSM - Multiply the sample weight (in grams) by 100 to get GSM.

Hydraulic GSM Cutter

Digital precision balance

digital precision balance

2/3/4/5 Digit Digital precision Balance

digital precision balance is a weight balance machine. It’s used to Low capacity balance. digital precision balance play an important role to accurate measurement. Digital precision balance is used to check weight paper, jewelry etc. It shows accurate result. We have the best collection of digital precision balance. MAAM TEX IS the best supplier of Precision Balance in Bangladesh

A Digital Precision Balance is a high-accuracy electronic weighing device used in laboratories, industries, and educational institutions for measuring mass with a high degree of precision. It is essential for tasks that require meticulous weight measurements, such as chemical analysis, formulation, and quality control. Key Features:- High Accuracy & Precision: - Typically offers readability from 0.1 g to 0.001 g (or even finer). - Ideal for weighing small amounts of material where accuracy is crucial.

- Digital Display: - Large, backlit LCD or LED display for easy reading. - Some models include touch screen interfaces.

- Tarring Function: - Allows you to subtract the weight of a container or packaging to get the net weight.

- Calibration: - Internal or external calibration to maintain accuracy over time. - Some advanced models have auto-calibration features.

- Weighing Units: - Supports multiple units like grams (g), milligrams (mg), carats (ct), and ounces (oz). Stable Platform: - Includes a draft shield to protect against air currents and vibrations, which can affect measurement accuracy.

- High Accuracy and Precision- Delivers extremely accurate weight measurements, often down to 0.001 g or better.- Crucial for experiments and applications where even slight variations can affect outcomes.

- User-Friendly Interface- Digital display makes readings easy to read and interpret.- Most models include intuitive controls for functions like tarring, unit conversion, and calibration.3. Speed and Efficiency- Provides instant, stable readings, saving time compared to manual or mechanical balances.- Streamlines lab workflows and enhances productivity.

- Versatile Applications- Suitable for various fields including chemistry, biology, pharmacology, food testing, and gemology.- Can handle diverse weighing tasks from solids to liquids and powders.

- Advanced Features- Tare Function: Subtracts the weight of containers automatically.- Multiple Weighing Units: Supports various measurement units.- Data Connectivity: Many models allow connection to computers or printers for data logging.

- Portability and Space Efficiency- Compact design fits easily in most laboratory setups.- Lightweight models are easy to move and store.

- Enhanced Safety and Reliability- Stable platform and draft shields reduce environmental interference.- Built-in calibration ensures ongoing accuracy.

Fatigue tester for Elastic fabric

Fatigue Tester for Elastic Fabric

Fatigue tester for Elastic fabric

- Adjustable Stretch Range - Allows setting stretch levels (e.g., 0–100%) to simulate real-life fabric use.

- High-Cycle Capability - Supports up to millions of stretch-relax cycles for long-term fatigue analysis.

- Touch Screen Control - 7-inch color display for easy setup, monitoring, and data entry.

- Servo Motor Driven - Ensures precise and smooth linear motion during testing.

- Customizable Speed - Adjustable test speed (e.g., up to 40 cycles per minute) based on test requirements.

- Multi-Sample Testing - Some models allow testing multiple specimens simultaneously.

- Cycle Counter with Alarm - Built-in counter with programmable stop after preset cycles and auto-alert feature.

- Durable Construction - Robust metal frame suitable for continuous testing in lab environments.

- Standard Compliance - Designed to follow standards like GB/T 37635 for elastic fabric testing.

- Prepare the Sample

- Mount the Sample - Secure both ends of the fabric in the upper and lower clamps.

- Set Test Parameters

- Start the Test - Press start on the touch screen interface. - The machine will cyclically stretch and release the sample.

- Monitor Progress - Observe operation or let it run automatically.

- Remove and inspect - Take out the fabric and measure elongation, recovery, or visual defects.

- Record and Compare Results - Compare with initial measurements or standard performance criteria.

Fatigue tester for Elastic fabric

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated