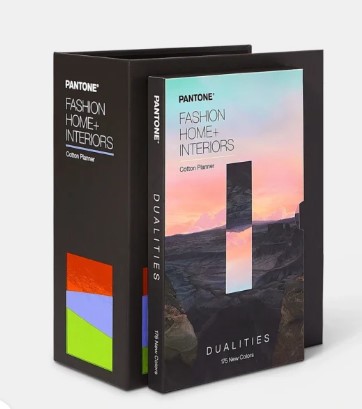

Pantone book

$0.00

Pantone Book

Pantone Book

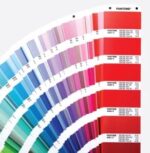

A Pantone Book, commonly referred to as a Pantone Color Guide, is a professional color matching tool used across industries like graphic design, fashion, printing, packaging, and product manufacturing. It helps ensure consistent color communication from design to final production.

What It Does?

– Displays standardized Pantone colors in fan-deck or chip book format.

– Provides color codes, ink formulas, and finish types for accurate color replication.

Types of Pantone Books:

- Formula Guide (Solid Coated & Uncoated) – For spot color printing.

- Color Bridge – Shows Pantone spot colors alongside CMYK equivalents.

- Pantone Fashion, Home + Interiors (FHI) – For textiles, soft goods, and home decor.

- Pantone CMYK and Pastels & Neons Guides – For process printing and special effect colors.

⚙️ Features of Pantone Book:

– Thousands of pre-defined colors.

– Ink mixing formulas (for printers).

– Available in coated, uncoated, and matte finishes.

– Some include digital tools or access to Pantone Connect software.

✅ Benefits of Pantone Book:

– Ensures accurate color matching across designers, clients, and manufacturers.

– Supports branding consistency across all printed and physical materials.

key benefits of using a Pantone Book:

✅ 1. Accurate Color Communication- Ensures consistent color matching between designers, printers, and manufacturers—globally.

✅ 2. Industry Standard- Trusted across printing, fashion, packaging, and branding for reliable color references.

✅ 3. Saves Time and Reduces Errors – Eliminates guesswork in color approval, helping avoid costly reprints or corrections.

✅ 4. Versatile Applications – Supports multiple media types: print, fabric, plastics, digital design, etc.

✅ 5. Real-World Color View – Physical swatches show true ink or dye appearance, which digital screens can’t replicate accurately.

✅ 6. Ink Mixing Formulas – Provides exact mixing guides for printers to replicate spot colors precisely.

✅ 7. Global Consistency – Helps maintain brand color consistency across international production sites.

key features of a Pantone Book:

1. Standardized Color System – Includes thousands of pre-defined Pantone Matching System (PMS) colors with unique codes.

2. Multiple Finish Types – Available in Coated (C), Uncoated (U), Matte (M) formats to match different printing surfaces.

3. Fan Deck or Chip Format – Comes in portable fan-deck or tear-away chip books for easy reference and sharing.

4. Ink Mixing Formulas – Provides precise ink formulas for each color, ideal for print production.

5. Specialized Editions – Guides tailored for graphic design, textiles (FHI), plastics, and digital design.

6. Cross-Media Consistency – Ensures uniform color across print, web, fabric, and packaging.

7. Digital Integration – Many books include access to Pantone Connect for digital workflow and color data sync.

Here’s a simple guide on how to use a Pantone Book effectively:

✅ 1. Choose the Right Pantone Book

– Use Formula Guide for print.

– Use FHI (Fashion, Home + Interiors) for textiles.

– Use Color Bridge to compare spot colors with CMYK.

✅ 2. Select the Color

– Flip through the fan deck or chip book to find the desired color.

– Note the Pantone code (e.g., Pantone 186 C for coated paper).

✅ 3. Communicate the Code

– Share the Pantone number with printers, manufacturers, or team members to ensure consistent color use.

✅ 4. Use the Right Finish – Make sure you’re referencing coated, uncoated, or matte depending on your final material.

✅ 5. Compare to Printed Proofs

– Use the physical Pantone swatch to check if print proofs or samples match.

✅ 6. Maintain Lighting Consistency

– View colors under standard lighting (D50) for accurate color judgment.

✅ 7. Store Properly – Keep the Pantone book in a cool, dry place and replace it every 12–18 months to avoid fading.

Pantone offers a diverse range of color guides tailored to various industries and applications. Here’s an overview of the main Pantone book models:

Pantone Graphics & Print Guides

- Formula Guide (Solid Coated & Uncoated)

– Features over 2,390 spot colors with corresponding ink formulations.

– Essential for branding, packaging, and print design.

– Provides accurate color matching for solid colors.

- Color Bridge Guide (Coated & Uncoated)

– Displays side-by-side comparisons of Pantone spot colors and their closest CMYK equivalents.

– Includes CMYK, RGB, and HEX values for digital and print consistency.

– Ideal for projects requiring color translation across different media.

- CMYK Guide (Coated & Uncoated)

– Contains a comprehensive range of CMYK colors.

– Useful for four-color process printing without spot colors.

– Helps in selecting colors achievable through standard CMYK printing.

- Pastels & Neons Guide

– Offers a collection of soft pastel and vibrant neon colors.

– Suitable for creative projects in fashion, print, and packaging.

– Provides unique color options for special design applications.

- Metallics Guide

– Features metallic spot colors for premium print finishes.

Ideal for luxury packaging, branding, and high-end print materials.

– Adds a sophisticated touch to printed designs.

Pantone Fashion, Home + Interiors (FHI) Guides

- FHI Color Guide (TPG – Paper)

– Contains a wide range of colors for non-fabric materials.

– Used in product design, cosmetics, and interiors.

– Provides color inspiration for various applications.

- FHI Cotton Passport & Cotton Planner (TCX – Textile)

– Offers colors on cotton fabric swatches.

– Essential for textile and apparel design.

– Ensures accurate color communication in fabric production.

- FHI Polyester Swatch Book

– Includes colors on polyester fabric.

– Useful for sportswear, footwear, and synthetic textiles.

– Provides color options specific to polyester materials.

Pantone Specialty Guides

- Pantone SkinTone Guide

– Features a range of skin tone colors.

– Used in cosmetics, healthcare, and product development.

– Aids in creating products that match diverse skin tones.

- Pantone Plastic Standard Chips

– Provides color references on plastic substrates.

– Essential for industrial design, consumer electronics, and appliances.

– Ensures color accuracy in plastic product manufacturing.

Pantone Bundles & Studio Sets

– Portable Guide Studio

– A comprehensive set including multiple Pantone guides.

– Designed for professionals needing a wide range of color references.

– Convenient for on-the-go color selection and matching.

– Essentials Set

– Combines key Pantone guides into one package.

– Ideal for designers seeking a versatile color toolkit.

– Offers a cost-effective solution for comprehensive color needs.

Each Pantone guide serves specific purposes across different industries. Selecting the appropriate guide depends on your project’s requirements and the materials involved.

Pantone Book

Related products

Perspiration Tester

Perspiration Tester

Perspiration Tester

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Stainless Steel Frame - Corrosion-resistant body for durability and long-term use.

- Multi-Sample Capacity - Can hold up to 20 or more specimens for batch testing.

- Standardized Loading Weight- Applies uniform pressure (usually 12.5 kPa) across all samples.

- Removable Plates - Glass or acrylic plates ensure even contact and easy cleaning.

- Compact Design- Space-saving, bench-top model ideal for lab environments.

- Complies with Test Standards - Meets ISO 105 E04, AATCC 15, and related perspiration fastness standards.

- Ease of Operation - Simple loading, unloading, and incubation process.

- High-Temperature Resistance - Can be used inside incubators at 37°C or ovens as required.

- Prepare the Test Solution - Mix artificial acidic or alkaline perspiration as per standard (ISO or AATCC).

- Cut the Fabric Samples - Cut both the test fabric and adjacent white fabric (usually cotton) to standard size.

- Soak the Samples - Immerse the fabric sandwich (test + adjacent) in the test solution for 30 minutes.

- Remove Excess Liquid - Gently squeeze or blot to remove extra moisture—do not dry.

- Load in the Tester- Place each sandwich between glass or acrylic separator plates in the tester.

- Apply Pressure - Tighten the top plate or place the standard weight on top to apply uniform pressure.

- Incubate - Keep the loaded tester in an oven or incubator at 37°C for 4–16 hours (depending on the method).

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Dry and Evaluate - Remove, air dry the samples, then assess color change and staining using a gray scale.

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

Perspiration Tester

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

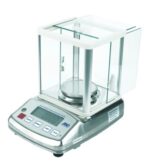

Digital precision balance

digital precision balance

2/3/4/5 Digit Digital precision Balance

digital precision balance is a weight balance machine. It’s used to Low capacity balance. digital precision balance play an important role to accurate measurement. Digital precision balance is used to check weight paper, jewelry etc. It shows accurate result. We have the best collection of digital precision balance. MAAM TEX IS the best supplier of Precision Balance in Bangladesh

A Digital Precision Balance is a high-accuracy electronic weighing device used in laboratories, industries, and educational institutions for measuring mass with a high degree of precision. It is essential for tasks that require meticulous weight measurements, such as chemical analysis, formulation, and quality control. Key Features:- High Accuracy & Precision: - Typically offers readability from 0.1 g to 0.001 g (or even finer). - Ideal for weighing small amounts of material where accuracy is crucial.

- Digital Display: - Large, backlit LCD or LED display for easy reading. - Some models include touch screen interfaces.

- Tarring Function: - Allows you to subtract the weight of a container or packaging to get the net weight.

- Calibration: - Internal or external calibration to maintain accuracy over time. - Some advanced models have auto-calibration features.

- Weighing Units: - Supports multiple units like grams (g), milligrams (mg), carats (ct), and ounces (oz). Stable Platform: - Includes a draft shield to protect against air currents and vibrations, which can affect measurement accuracy.

- High Accuracy and Precision- Delivers extremely accurate weight measurements, often down to 0.001 g or better.- Crucial for experiments and applications where even slight variations can affect outcomes.

- User-Friendly Interface- Digital display makes readings easy to read and interpret.- Most models include intuitive controls for functions like tarring, unit conversion, and calibration.3. Speed and Efficiency- Provides instant, stable readings, saving time compared to manual or mechanical balances.- Streamlines lab workflows and enhances productivity.

- Versatile Applications- Suitable for various fields including chemistry, biology, pharmacology, food testing, and gemology.- Can handle diverse weighing tasks from solids to liquids and powders.

- Advanced Features- Tare Function: Subtracts the weight of containers automatically.- Multiple Weighing Units: Supports various measurement units.- Data Connectivity: Many models allow connection to computers or printers for data logging.

- Portability and Space Efficiency- Compact design fits easily in most laboratory setups.- Lightweight models are easy to move and store.

- Enhanced Safety and Reliability- Stable platform and draft shields reduce environmental interference.- Built-in calibration ensures ongoing accuracy.

Fatigue tester for Elastic fabric

Fatigue Tester for Elastic Fabric

Fatigue tester for Elastic fabric

- Adjustable Stretch Range - Allows setting stretch levels (e.g., 0–100%) to simulate real-life fabric use.

- High-Cycle Capability - Supports up to millions of stretch-relax cycles for long-term fatigue analysis.

- Touch Screen Control - 7-inch color display for easy setup, monitoring, and data entry.

- Servo Motor Driven - Ensures precise and smooth linear motion during testing.

- Customizable Speed - Adjustable test speed (e.g., up to 40 cycles per minute) based on test requirements.

- Multi-Sample Testing - Some models allow testing multiple specimens simultaneously.

- Cycle Counter with Alarm - Built-in counter with programmable stop after preset cycles and auto-alert feature.

- Durable Construction - Robust metal frame suitable for continuous testing in lab environments.

- Standard Compliance - Designed to follow standards like GB/T 37635 for elastic fabric testing.

- Prepare the Sample

- Mount the Sample - Secure both ends of the fabric in the upper and lower clamps.

- Set Test Parameters

- Start the Test - Press start on the touch screen interface. - The machine will cyclically stretch and release the sample.

- Monitor Progress - Observe operation or let it run automatically.

- Remove and inspect - Take out the fabric and measure elongation, recovery, or visual defects.

- Record and Compare Results - Compare with initial measurements or standard performance criteria.

Fatigue tester for Elastic fabric

Color fastness to washing machine

COLOR FASTNESS TO WASHING MACHINE

Color fastness to washing machine refers to a fabric’s resistance to fading or bleeding when subjected to washing processes. This test measures how well the dye or colorant stays on the fabric when exposed to water, detergent, heat, and mechanical action—conditions typically found in household or industrial washing machines. Purpose of Color fastness to washing machine - To evaluate the durability of dyed or printed textiles during laundering.- Essential for determining fabric quality and suitability for end-use (e.g., clothing, upholstery). Test Method Usually based on international standards such as: - ISO 105-C06 - AATCC 61- IS 3361- AATCC 28/61/132/151/190, BS 1006 C01-C05, ISO 105 Part C01-C06/C08/D01, M&S C4/C5/C10A/P3B, FTMS 191-5610, NEXT TM2/3/5, GB/T 5711/3921 Procedure (Simplified)1. Sample Preparation: - A fabric specimen is stitched with undyed adjacent fabrics (usually cotton or wool).2. Washing: - Washed in a laboratory washing machine using standard detergent, water, and specific temperature/time settings (e.g., 40°C for 30 minutes).- Drying: - After washing, the sample is dried, typically air-dried or tumble-dried.4. Evaluation: - Color change and staining on adjacent fabrics are assessed using a gray scale (1 to 5 scale; 5 = no change, 1 = severe change). - Results may also be evaluated visually under standard lighting.

- Supports Brand Reputation - Reliable color fastness contributes to a premium product image and consistent performance.4. Compliance with Standards - Meets industry requirements (e.g., ISO, AATCC), crucial for export, certifications, and regulatory compliance.

- Improves Process Control- Helps identify dyeing or finishing process issues early, leading to better production control.6. Reduces Rework and Waste - Minimizes production losses due to color defects after washing.

- Essential for Specific End Uses - Critical for items subject to frequent washing (e.g., uniforms, baby clothes, hospital linens).8. Supports Material Selection - Guides textile manufacturers in choosing appropriate dyes and fabrics for specific applications.

- Assessment of Color Change and Staining- Evaluates both the fabric’s color retention and the staining of adjacent fabrics using grey scales (1 to 5 rating).4. Multi-Fiber Fabric Use - Tests include fabric stitched with adjacent test strips (cotton, wool, etc.) to assess color bleeding onto different fibers.

- Multiple Test Options - Includes domestic, accelerated, and industrial washing conditions depending on the end-use of the fabric.6. Temperature and Time Control - Precise control over wash temperature (e.g., 40°C, 60°C) and duration (e.g., 30 mins), simulating specific washing cycles.

- Detergent and Additive Use - Uses standardized detergent formulations with/without optical brighteners, and sometimes alkaline or oxidizing agents.8. Reproducible and Quantifiable - Provides repeatable results that can be objectively measured and documented.

- Applicability to All Textile Types - Suitable for dyed, printed, or coated fabrics across various fibers (cotton, polyester, blends, etc.).

- Rate of temperature rise: Maximum speed for 2ºC/min 7. Internal materials: Imported Stainless Steel 316L 8. Control panel: Touch screen

- Rack point control function helps to replace containers easily 10. Safety device: Safety door switch, over-temperature protector and dry heating protector 11. Heating media: Distilled water 12. Power supply: AC220V 50Hz 30A

Bursting strength tester

Bursting strength tester

true burst

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

- Bursting pressure can reach up to 1.2MPa 5. The maximum burst and expansion degree can reach 70mm. 6. Strengthen the lighting system on the test surface. 7. The main aerodynamic force helps to clamp the sample system. 8. A variety of test areas are available, and the switching is easy.

- A variety of unit conversions between Chinese and English. 10. Reliable anti-pinch safety protection design. [Technical parameter]: 1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized) 2. The minimum graduation value: 0.0001Mpa 3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree pressurization.

Stretch Recovery Tester Static Method

Stretch Recovery Tester Static Method

Stretch Recovery Tester

- A sample is stretched to a predetermined extension or force.

- The stretch is maintained for a set period.

- After removing the load, the recovery (return to original length) is measured after a fixed time.

- The fabric sample is clamped and stretched to a specific length or force.

- It’s held for a fixed duration (e.g., 1–5 minutes).

- The tension is released, and the sample is allowed to recover.

- The recovered length is measured after a set time.

Stretch Recovery Tester

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated