Laboratory mini stenter Dryer

$0.00

Laboratory mini stenter Dryer

A Laboratory Mini Stenter Dryer is a compact, lab-scale machine designed to simulate the drying and heat-setting processes used in textile finishing. It mimics the function of industrial stenter machines but on a much smaller scale, making it ideal for testing fabric behavior, shrinkage, and finish quality under controlled conditions.

Key Features:

- Controlled Heating System

– Typically uses electric heating with adjustable temperature (up to 220–250°C).

– Ensures uniform and precise temperature control.

- Adjustable Fabric Width

– Equipped with clips or pins to hold and stretch fabric width-wise, simulating stenter frame action.

- Variable Speed Conveyor – Allows control over fabric dwell time for drying or heat-setting.

- Compact and Bench-Top Design – Space-saving design ideal for textile labs and R&D units.

- Digital Controls – Easy-to-use digital interface for setting temperature, conveyor speed, and process time.

- Transparent Viewing Window – Allows operators to monitor fabric movement and drying visually.

- Low Energy Consumption – Designed for lab use, consuming less power than industrial models.

Applications:

– Heat-setting of synthetic fabrics. Drying and curing of samples post-dyeing or printing.

– Evaluating fabric shrinkage, dimensional stability, and finish behavior.

– Testing chemicals and auxiliaries used in textile finishing.

Benefits of Laboratory Mini Stenter Dryer:

- Accurate Simulation of Production – Mimics industrial stenter conditions on a lab scale, ideal for pre-production testing and R&D.

- Cost-Effective Testing – Enables testing and fabric finishing without the high cost or space requirements of full-scale machines.

- Energy Efficient – Consumes less power compared to large stenters, making it economical for small-scale or frequent use.

- Precise Control – Offers accurate control of temperature, speed, and fabric tension, ensuring consistent results.

- Space-Saving Design – Compact and bench-top friendly, perfect for laboratories with limited space.

- Multiple Applications – Useful for drying, heat-setting, shrinkage testing, and evaluating chemical finishes.

- Faster Development Cycles – Speeds up new product development by allowing rapid sample testing and adjustments.

- Improved Fabric Quality – Helps optimize finishing parameters for better dimensional stability, hand feel, and appearance.

- Safe and User-Friendly- Designed with lab safety in mind, including temperature safety controls and easy operation.

Features of Laboratory Mini Stenter Dryer:

- Compact Bench-Top Design – Ideal for laboratory use with limited space requirements.

- Adjustable Temperature Control – Precise heating (usually up to 220–250°C) with digital controllers for accurate processing.

- Variable Conveyor Speed- Allows adjustment of fabric dwell time for different drying or heat-setting needs.

- Width Adjustment Mechanism – Equipped with clips or pins to stretch and fix fabric width-wise, simulating industrial stenter conditions.

- Transparent Viewing Window – Enables visual monitoring of fabric movement and drying inside the chamber.

- Digital Display Panel- Easy-to-use interface for setting and monitoring temperature, speed, and time.

- Stainless Steel Construction- Durable and corrosion-resistant for long-term use at high temperatures.

- Uniform Heat Distribution- Ensures consistent fabric treatment across the width.

- Safety Features- Over-temperature protection and insulated body for operator safety.

- Versatile Applications – Suitable for drying, heat-setting, shrinkage testing, and chemical finish evaluations.

Laboratory Mini Stenter Dryer dealer In Bangladesh,

Lab Mini Stenter Dryer Importer in Bangladesh,

Mini Stenter Dryer in Bangladesh,

Laboratory Stenter Dryer in Bd,

Lab Stenter Dryer In Uttara,

Lab Stenter Price in Bangladesh,

Laboratory Stenter Dryer in Bangladesh,

Laboratory Mini Dryer in Bangladesh,

Automatic fixing dryer

Application:

used for simulating the production onsite to produce the textile that meets customer requirement,

including the time、temperature、resin auxiliary agent formula, elongation of the same textile, and

it is also can provide basis manufacture and to ensure the correctness of mass production.

Basic design as Automatic Fixing Dryer,also connect external steam for printing sample

steaming. Owing the wide adjusting ranges regarding temperature, humidity, dwelling time, this

apparatus can be used for :

a) Electric heating for drying, curing and thermofixation, room temp.~230℃.

b) Steaming with saturated steam 102±2℃

c) Electric heating and steam together for HT steaming between 102±230℃

Textile Testing Instruments

Automatic Fixing Dryer dealer In Bangladesh,

Automatic Fixing Dryer Importer in Bangladesh,

Automatic Fixing Dryer in Bangladesh,

Automatic Fixing Dryer in Bd,

Automatic Fixing Dryer In Uttara,

Automatic Fixing Dryer Price in Bangladesh,

Automatic Fixing Dryer Supplier in Bangladesh,

Lab Dryer Machine in Bangladesh,

Rapid Dryer Mini Stanter in Bangladesh

Related products

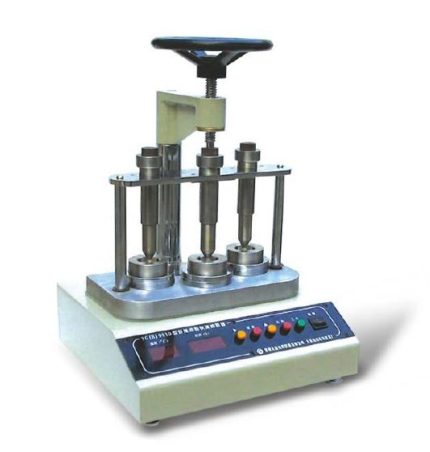

Digital Elmendorf tearing tester

Digital Elmendorf Tearing Tester

Digital Elmendorf Tearing Tester is a precision instrument used to measure the tear strength of materials like woven fabrics, paper, plastic films, and nonwovens. It determines how much force is required to continue tearing a pre-slit sample. Key Functions of Digital Elmendorf Tearing Tester: - Measures propagation tear resistance, not initial tear. - Uses a pendulum to apply force; the energy lost during tearing is calculated to determine tear strength. - Equipped with a digital display for direct reading of results in grams or millinewtons. Core Components: - Pendulum Arm: Applies tearing force. - Clamps: Secure the sample before and after the tear. - Cutting Blade: Creates a precise slit at the start of the test. - Digital Display Unit: Shows the tearing force result clearly and instantly. - Counterweights: Optional weights for increasing test range (for stronger materials). Applications of Digital Elmendorf Tearing Tester: - Testing tear resistance of: - Textile fabrics (especially woven) - Paper and cardboard - Plastic films - Nonwovens - Packaging materials Benefits of Digital Elmendorf Tearing Tester:- Accurate Tear Strength Measurement - Provides precise data on tear resistance, critical for quality control and product performance.

- Digital Readout - Easy-to-read display gives instant, reliable results without manual calculations.

- High Reproducibility - Ensures consistent test outcomes due to controlled tearing angle and speed.

- Fast Testing Process - Simple loading and quick test cycle increase lab efficiency.

- Suitable for Various Materials - Tests a wide range of flexible materials like textiles, paper, plastic, and packaging.

- Customizable Range - Use of optional weights extends the test range for low to high tear strength materials.

- Low Sample Waste - Requires small fabric or material samples, reducing waste during testing.

- Standards Compliance - Meets international testing standards (e.g., ASTM D1424, ISO 13937) for credibility and uniformity.

- Precision Sample Clamp - Securely holds samples in place to ensure accurate tear initiation.

- Pre-Cutting Blade - Integrated knife creates a precise initial slit in the sample before tearing.

- User-Friendly Interface - Simple buttons and screen navigation for ease of operation.

- Standard Test Compliance - Compatible with ASTM D1424, ISO 1974, ISO 13937, and other tear strength standards.

- Sturdy Construction - Made with durable materials for long-lasting performance and stable operation.

- Compact Design - Space-efficient footprint ideal for laboratory environments.

- Data Output Options- Some models offer USB or printer connectivity for result documentation.

- Prepare the Sample - Cut the material (fabric, paper, film, etc.) to standard size (typically 100 × 63 mm for textiles) and slit it with the pre-cutter as required.

- Select Pendulum Weight - Choose the appropriate pendulum or add counterweights based on expected tear strength.

- Calibrate the Machine - Set the pendulum to its starting position and zero the display.

- Clamp the Sample - Fix one half of the sample in the stationary clamp and the other in the moving clamp.

- Cut the Initial Slit - Use the integrated blade to make a precise cut at the marked slit area (usually 20 mm).

- Release the Pendulum - Trigger the pendulum to swing and tear the sample through the pre-slit.

- Read the Result - The digital display will show the tearing force automatically (in g, mN, or cN).

- Record or Export Data - Save or print the result if your model supports USB or printer connection.

- Reset for Next Test - Reposition the pendulum and prepare a new sample for the next cycle.

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.)

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.) ICI Pilling & Snagging Test Machine

Fabric drape tester

Fabric Drape Tester

Fabric Drape Tester is a lab device used to measure the drape ability of fabric—how it hangs under its own weight. It assesses how fabric conforms in folds or waves, which affects garment appearance and comfort. Purpose of Fabric Drape Tester: To evaluate the aesthetic and functional behavior of a fabric when suspended, especially important in apparel and home textiles. Working Principle: A circular fabric specimen is placed over a smaller disc. The unsupported edges drape downward. A light source casts a shadow of the draped shape onto a recording surface or scanner. The area of the shadow is measured to calculate the drape coefficient. Main Components of Fabric Drape Tester: - Rotating Support Disc: Holds the fabric. - Light Source: Projects the drape shadow. - Paper or Digital Scanner: Captures the drape outline. - Template: For cutting fabric to standard test size. - Software or Plan meter: Calculates the drape coefficient. Applications of Fabric Drape Tester: - Fashion and apparel design - Fabric development - Quality control in woven, knitted, or nonwoven fabrics Benefits of Fabric Drape Tester:- Quantifies Fabric Flow - Measures drape behavior accurately, crucial for garments and furnishings.

- Supports Design Decisions - Helps designers select fabrics that match the intended look and movement of a product.

- Improves Garment Fit and Comfort - Ensures fabrics behave naturally on the body, enhancing wear ability.

- Enhances Product Aesthetics - Prevents stiff or limp fabric choices in fashion, interior, or technical textiles.

- Standardized Evaluation - Enables comparison across fabrics using drape coefficient, based on standards (e.g., BS 5058).

- Supports R&D - Useful in developing new fabrics or finishes to improve drape quality.

- Non-Destructive Testing - Tests fabric without damaging it, allowing for further analysis.

- Boosts Quality Control - Identifies batch inconsistencies or performance issues early in production.

- Rotating Support Disc - Holds the fabric sample over a smaller disc to create natural drape.

- Standard Sample Size Support - Designed for circular fabric samples, usually 30 cm in diameter.

- Light Projection System - Projects the draped fabric’s shadow onto a screen or recording surface.

- Drape Coefficient Calculation - Measures the shadow area to compute the drape coefficient (percentage of unsupported area covered by the shadow).

- Digital or Manual Options - Available in models with digital image processing or manual plan meter tracing.

- Stable Base and Structure - Ensures consistent and vibration-free testing conditions.

- Sample Templates Provided - For cutting precise, standard-sized fabric specimens.

- User-Friendly Interface - Simple controls for rotation and light alignment.

- Compact and Lab-Ready Design - Fits easily on lab benches and in testing environments.

- Compliance with Testing Standards - Supports BS 5058 and other relevant drape measurement methods.

- Prepare the Fabric Sample - Cut a circular fabric sample, typically 30 cm in diameter, using the provided template.

- Place the Fabric - Center the fabric sample over the smaller support disc (usually 18 cm diameter) on the tester.

- Turn on the Light Source - Illuminate the fabric from above so it casts a shadow onto the recording surface or paper below.

- Capture the Shadow Outline - Trace the shadow manually on paper or capture it digitally, depending on the model.

- Measure the Shadow Area - Use a plan meter (manual) or software (digital) to determine the shadow’s area.

- Calculate Drape Coefficient (DC) - Use the formula:

- Record the Result - Log the drape coefficient to evaluate how stiff or flexible the fabric is.

- Repeat for Accuracy - Test multiple samples and average the results for consistency.

It is used for testing dynamic and static drape properties

(drape coefficient, shape change rate, surface ripple and drape uniformity, etc.)

of various fabrics.

Related standards GB/T23329 FZ/01045 BS5058 etc.

Instrument characteristics

1. CCD imaging, dynamic and static image processing.

2. A variety of charts and data statistics, analysis, storage, output

3. No need to replace background color, can test all kinds of color samples.

4. Work mode:Microcomputer control, CCD imaging, automatic processing of images and data automatically.

Technical parameters

1. Communication interface: RS232, USB

2. Image sensor: CCD sensor.

3. Static (dynamic) state draping coefficient: 0 ~ 100% + 2

4. Drapability uniformity: 0 ~ 100% + 2

5. The rate of morphological change is 0 to 100% + 2.

6. Surface waviness error: + 1

It is used for testing dynamic and static drape properties

(drape coefficient, shape change rate, surface ripple and drape uniformity, etc.)

of various fabrics.

Related standards GB/T23329 FZ/01045 BS5058 etc.

Instrument characteristics

1. CCD imaging, dynamic and static image processing.

2. A variety of charts and data statistics, analysis, storage, output

3. No need to replace background color, can test all kinds of color samples.

4. Work mode:Microcomputer control, CCD imaging, automatic processing of images and data automatically.

Technical parameters

1. Communication interface: RS232, USB

2. Image sensor: CCD sensor.

3. Static (dynamic) state draping coefficient: 0 ~ 100% + 2

4. Drapability uniformity: 0 ~ 100% + 2

5. The rate of morphological change is 0 to 100% + 2.

6. Surface waviness error: + 1 Spray Rating Tester

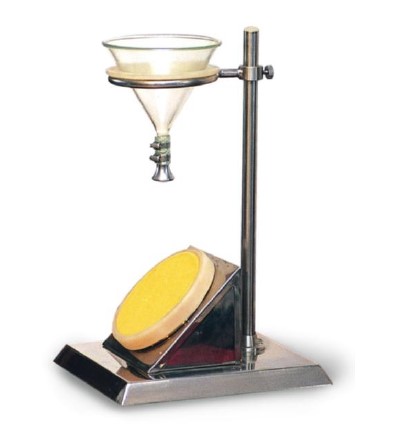

Spray Rating Tester

Spray Rating Tester

- Quick and Simple Evaluation - Offers a fast way to assess fabric water repellency without complex setup.

- Standardized Testing- Complies with AATCC 22 and ISO 4920, ensuring globally accepted results.

- Cost-Effective- Low maintenance and no power requirement make it economical for routine lab use.

- Improves Fabric Performance - Helps manufacturers develop or improve water-resistant textiles.

- Non-Destructive Test - Does not damage the fabric, allowing for additional tests on the same sample.

- Visual Grading- Easy to interpret using a standard spray rating chart (0 to 100 scale).

- Supports Quality Control - Detects finish degradation or variation in water-repellent treatments.

- Portable and Compact- Lightweight design allows easy use in various lab or field settings.

- Standardized Spray Nozzle - Delivers consistent water spray per AATCC and ISO specifications.

- 45° Specimen Mounting Angle - Ensures uniform test setup for accurate and repeatable results.

- Stainless Steel or Aluminum Frame - Corrosion-resistant and durable for long-term use with water exposure.

- Water Reservoir and Funnel System - Provides precise water volume (usually 250 ml) for each test.

- Graduated Spray Stand- Fixed height (150 mm above specimen) for controlled spray impact.

- Detachable Specimen Holder- Easy loading and removal of fabric samples.

- Compact and Lightweight Design - Portable and convenient for both lab and field testing.

- No Electricity Required - Fully manual operation increases reliability and reduces operating costs.

- Prepare the Sample - Cut fabric to standard size (usually 180 × 180 mm). - Condition the sample if required (21°C, 65% RH for 24 hours).

- Mount the Fabric - Place the fabric on the specimen holder at a 45° angle.

- Fill the Reservoir - Pour 250 ml of distilled water into the upper funnel.

- Start the Test - Release the water through the nozzle; it sprays over the fabric for about 25–30 seconds.

- Inspect the Fabric - After spraying, visually assess the water beading or penetration on the surface.

- Rate the Sample - Compare the fabric’s wetting pattern with the standard spray rating chart: - 100 = No sticking/wetting - 90–50 = Partial wetting - 0 = Complete wetting

- Record the Rating - Document the spray rating for quality control or reporting.

Spray Reting Tester

[Scope of application]:

Used for the determination of moisture resistance (wetting grade) of various fabrics

which have been or have not been treated with water resistance or water repellency.

[related standards]:

GB/T4745 ISO4920 AATCC22 JISL1092 etc.

[technical parameters]:

1. Glass funnel:150 x 150 (capacity 500ml)

2. Specimen placement angle:The level is 45 degrees.

3. Distance from nozzle to sample center:150mm

4. Specimen diameter:Ф150mm

5. Size of water receiving pan:500×400×30mm

6. Matching measuring cups:500ml

7, size 500 x 400 x 500mm

8. Instrument weight:5Kg

Spray Reting Tester

[Scope of application]:

Used for the determination of moisture resistance (wetting grade) of various fabrics

which have been or have not been treated with water resistance or water repellency.

[related standards]:

GB/T4745 ISO4920 AATCC22 JISL1092 etc.

[technical parameters]:

1. Glass funnel:150 x 150 (capacity 500ml)

2. Specimen placement angle:The level is 45 degrees.

3. Distance from nozzle to sample center:150mm

4. Specimen diameter:Ф150mm

5. Size of water receiving pan:500×400×30mm

6. Matching measuring cups:500ml

7, size 500 x 400 x 500mm

8. Instrument weight:5Kg Xenon Arc Light Fastness Tester

HTHP Glycerin bath dyeing machine

HTHP Glycerin Bath Dyeing Machine

HTHP dyeing machine

- High Temperature Capability - Operates up to 140°C or more, ideal for disperse dyeing of polyester which requires elevated temperatures.

- Glycerin as Heat Transfer Medium - Glycerin allows for precise and uniform heating beyond the boiling point of water, without pressure buildup as in steam-based systems.

- Small Sample Dyeing - Used for lab-scale dyeing of fabric or yarn samples (commonly 5–10 g per tube), useful in R&D or color matching.

- Multiple Sample Capacity - Usually has multiple dyeing tubes/chambers for simultaneous dyeing of several samples under identical conditions.

- Accurate Temperature and Time Control - Digital or microprocessor-based controllers regulate temperature, heating rate, and timing precisely.

- Uniform Dyeing - Ensures even dye penetration due to consistent heat distribution and controlled rotation or agitation.

- Energy Efficient Glycerin’s heat retention reduces energy consumption compared to steam systems.

- Compact and Durable Design - Bench-top design, made from stainless steel and heat-resistant components for long life and lab use.

- Uniform Heating with Glycerin - Glycerin provides consistent heat transfer, ensuring even dye uptake and minimizing shade variation.

- Energy Efficient- Glycerin retains heat longer, reducing energy consumption compared to traditional steam-based dyeing.

- Accurate Process Control - Precise temperature and time control enhance reproducibility and dyeing consistency.

- Ideal for Lab and Sample Work - Perfect for R&D, shade matching, and recipe development with small fabric or yarn samples.

- Multi-Sample Dyeing - Allows multiple samples to be dyed simultaneously under identical conditions, saving time and effort.

- Compact and Safe - Bench-top design fits in laboratories and is safer than high-pressure steam systems.

- Low Maintenance - Simplified operation and fewer mechanical parts compared to steam-based systems lower upkeep needs.

- Faster Dyeing Cycles- Glycerin heats and cools quickly, reducing overall dyeing time.

- High-Temperature Operation - Capable of dyeing up to 140–150°C, suitable for synthetic fibers like polyester.

- Glycerin as Heat Medium - Uses glycerin for uniform, efficient heat transfer without generating high steam pressure.

- Multiple Dyeing Chambers - Usually equipped with 6–24 tubes for simultaneous multi-sample dyeing under identical conditions.

- Digital Temperature Controller- Offers precise control of temperature, time, and heating rate with programmable settings.

- Compact and Lab-Friendly Design - Bench-top model, easy to operate in laboratory environments with limited space.

- Stainless Steel Construction - Corrosion-resistant and durable for long-term, high-temperature operation.

- Safety Features - Includes over-temperature protection and thermal insulation to prevent heat loss and ensure operator safety.

- Agitation or Sample Rotation- Some models offer rotation or agitation for uniform dye penetration.

- Energy Efficient Heating - Glycerin’s heat retention improves energy efficiency over water- or steam-based systems.

- Low Maintenance - Simplified mechanical system reduces the need for frequent servicing.

Fiber Oil Fast Extractor

Fiber Oil Fast Extractor

A Fiber Oil Fast Extractor is a laboratory instrument designed to determine the oil or finish content in fibers, yarns, or fabrics, particularly wool and synthetic materials. It operates on the principle of solvent extraction followed by evaporation. Working Principle of Fiber Oil Fast Extractor:- Sample Preparation: Cut the fabric or fiber into small pieces.

- Solvent Addition: Place the sample into a metal tube and add an appropriate solvent (e.g., petroleum ether, ethyl ether).

- Extraction: Apply weight to the sample to facilitate the dissolution of oils into the solvent.

- Evaporation: The solvent-oil mixture drips onto a heated plate where the solvent evaporates, leaving behind the oil.

- Measurement: Weigh the remaining oil and calculate its percentage relative to the initial sample mass.

- Accurate Oil Content Measurement- Precisely determines oil or finish content in fibers, crucial for quality control.

- Rapid Extraction Process - Delivers fast results, improving lab efficiency and productivity.

- Simultaneous Multi-Sample Testing - Multiple workstations (e.g., 4 at once) reduce testing time for bulk samples.

- Improved Product Quality - Helps maintain consistent oil levels, which affect dyeing, processing, and fabric performance.

- Automatic Operation - Automated pressing and heating reduce manual effort and operator error.

- Digital Monitoring - Built-in timer, temperature control, and oil calculator enhance accuracy and usability.

- Compliance with Standards - Supports industry methods like GB/T 6504-2017, ensuring reliable and standard-compliant results.

- Safe Solvent Handling - Enclosed design minimizes solvent exposure and evaporation loss.

- Multiple Test Stations - Usually equipped with 2 to 4 independent work units for parallel testing.

- Automatic Weight Pressing System - Applies consistent pressure on samples for uniform solvent extraction.

- Microcomputer Temperature Control - Maintains precise heating (typically 90–120°C) with ±1°C accuracy.

- Built-in Timer and Calculator - Allows setting extraction time and calculates oil content directly.

- Solvent Evaporation Plate- Heats and evaporates solvent quickly, leaving only the oil residue.

- Digital Display - Shows time, temperature, and process status for user-friendly operation.

- Compact and Durable Design - Made with corrosion-resistant materials suited for chemical handling.

- Safety Features - Includes overheat protection and enclosed solvent chamber to reduce exposure risk.

- Standard Compliant - Designed to meet GB/T 6504-2017 and similar industry testing standards.

- Prepare the Sample - Cut 5–10 g of fiber or yarn into small pieces and place in the sample tube.

- Add Solvent - Pour a suitable solvent (e.g., petroleum ether) into the tube to cover the sample.

- Apply Weight - Place the extractor's weight or press system onto the sample to aid extraction.

- Start Extraction - Activate the machine. The solvent dissolves the oils and flows to the heating plate.

- Heat for Evaporation - Set the temperature (typically 90–120°C). The solvent evaporates, leaving oil on the plate.

- Measure Oil Content- After drying, weigh the remaining oil. Use the built-in calculator or formula:

- Clean the Unit - After cooling, clean all parts to prepare for the next test.

Fiber Oil Fast Extractor

Color fastness to washing machine

COLOR FASTNESS TO WASHING MACHINE

Color fastness to washing machine refers to a fabric’s resistance to fading or bleeding when subjected to washing processes. This test measures how well the dye or colorant stays on the fabric when exposed to water, detergent, heat, and mechanical action—conditions typically found in household or industrial washing machines. Purpose of Color fastness to washing machine - To evaluate the durability of dyed or printed textiles during laundering.- Essential for determining fabric quality and suitability for end-use (e.g., clothing, upholstery). Test Method Usually based on international standards such as: - ISO 105-C06 - AATCC 61- IS 3361- AATCC 28/61/132/151/190, BS 1006 C01-C05, ISO 105 Part C01-C06/C08/D01, M&S C4/C5/C10A/P3B, FTMS 191-5610, NEXT TM2/3/5, GB/T 5711/3921 Procedure (Simplified)1. Sample Preparation: - A fabric specimen is stitched with undyed adjacent fabrics (usually cotton or wool).2. Washing: - Washed in a laboratory washing machine using standard detergent, water, and specific temperature/time settings (e.g., 40°C for 30 minutes).- Drying: - After washing, the sample is dried, typically air-dried or tumble-dried.4. Evaluation: - Color change and staining on adjacent fabrics are assessed using a gray scale (1 to 5 scale; 5 = no change, 1 = severe change). - Results may also be evaluated visually under standard lighting.

- Supports Brand Reputation - Reliable color fastness contributes to a premium product image and consistent performance.4. Compliance with Standards - Meets industry requirements (e.g., ISO, AATCC), crucial for export, certifications, and regulatory compliance.

- Improves Process Control- Helps identify dyeing or finishing process issues early, leading to better production control.6. Reduces Rework and Waste - Minimizes production losses due to color defects after washing.

- Essential for Specific End Uses - Critical for items subject to frequent washing (e.g., uniforms, baby clothes, hospital linens).8. Supports Material Selection - Guides textile manufacturers in choosing appropriate dyes and fabrics for specific applications.

- Assessment of Color Change and Staining- Evaluates both the fabric’s color retention and the staining of adjacent fabrics using grey scales (1 to 5 rating).4. Multi-Fiber Fabric Use - Tests include fabric stitched with adjacent test strips (cotton, wool, etc.) to assess color bleeding onto different fibers.

- Multiple Test Options - Includes domestic, accelerated, and industrial washing conditions depending on the end-use of the fabric.6. Temperature and Time Control - Precise control over wash temperature (e.g., 40°C, 60°C) and duration (e.g., 30 mins), simulating specific washing cycles.

- Detergent and Additive Use - Uses standardized detergent formulations with/without optical brighteners, and sometimes alkaline or oxidizing agents.8. Reproducible and Quantifiable - Provides repeatable results that can be objectively measured and documented.

- Applicability to All Textile Types - Suitable for dyed, printed, or coated fabrics across various fibers (cotton, polyester, blends, etc.).

- Rate of temperature rise: Maximum speed for 2ºC/min 7. Internal materials: Imported Stainless Steel 316L 8. Control panel: Touch screen

- Rack point control function helps to replace containers easily 10. Safety device: Safety door switch, over-temperature protector and dry heating protector 11. Heating media: Distilled water 12. Power supply: AC220V 50Hz 30A

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated