GSM Cutter with Balance

$0.00

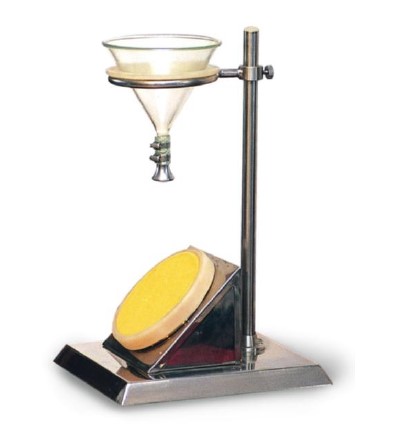

GSM Cutter with Balance

GSM Cutter with Balance

A GSM Cutter with Balance is a lab toolset used to determine the GSM (Grams per Square Meter) of fabrics, which indicates the fabric’s weight and density. The kit includes a GSM round cutter and a precision weighing balance.

Purpose GSM Cutter with Balance:

To accurately measure the weight per unit area of textile, paper, or nonwoven samples for quality control and product classification.

How It Works:

GSM Cutter: – A circular blade cuts a fixed area (usually 100 cm²) from the fabric.

Weighing Balance: – The cut piece is weighed, and the result is multiplied by 100 to get GSM.

GSM = Weight (in grams) × 100

Applications of GSM Cutter with Balance:

Textile and garment industry

Nonwovens and paper manufacturing

QC labs and R&D

Benefits of GSM Cutter with Balance:

Accurate GSM Measurement – Ensures precise fabric weight analysis for quality control.

Quick and Simple Operation – Allows fast sampling and GSM calculation in minutes.

No Need for Area Calculation – Cutter gives a fixed area (usually 100 cm²), simplifying the formula.

Improves Product Consistency – Helps maintain uniform fabric weight across batches.

Portable and User-Friendly – Compact design makes it ideal for labs and production floors.

Cost-Effective Tool – Offers high accuracy without the need for expensive equipment.

Versatile Use – Suitable for fabrics, paper, leather, films, and more.

Features of GSM Cutter with Balance:

Rotary Blade Cutter – Stainless steel blades for clean and accurate circular cuts.

Fixed Sample Area – Typically 100 cm², eliminating the need for area measurement.

Precision Digital Balance – Measures in grams with high resolution (0.01 g or better).

Rubber Cutting Pad – Protects blade and provides a smooth surface for cutting.

Safety Lock – Prevents accidental blade exposure.

Compact & Durable Design- Long-lasting, lab-friendly construction.

How to Use GSM Cutter with Balance:

Prepare the Fabric Sample- Place the fabric on the rubber cutting pad.

Cut the Sample – Hold the GSM cutter firmly and rotate it to cut a 100 cm² circular sample.

Turn on the Balance – Power up the digital weighing scale and tare it to zero.

Weigh the Sample – Place the cut fabric piece on the balance and note the weight in grams.

Calculate GSM – Multiply the weight by 100 to get GSM. – GSM = Sample weight (g) × 100

Record the Result- Log the GSM value for quality control or analysis.

Clean and Store – Wipe the cutter and balance, and store them safely after use.

GSM Calculation Formula:

GSM (g/m²) = (Weight of Sample in grams) × 100

When using a GSM cutter (100 cm²):

The cutter gives a fixed area of 100 cm², which is 1/100th of a square meter.

So, multiplying the sample’s weight by 100 gives the GSM directly.

Example:

If the sample weighs 1.75 g, then:

GSM = 1.75 × 100 = 175 g/m²

Balance Calibration Guide (Manual Calibration):

Warm-Up – Turn on the balance and let it warm up for 10–15 minutes if required.

Level the Balance – Use the built-in bubble level and adjust leveling feet until the bubble is centered.

Tare the Balance – Press the “TARE” or “ZERO” button to reset the display to 0.000 g.

Enter Calibration Mode – Press the “CAL” or “MODE” button (depends on the model).

– Some balances may require holding the button for a few seconds.

Use Standard Weight – When prompted, place a certified calibration weight (e.g., 100g, 200g) on the pan. – Wait for the display to stabilize.

Confirm Calibration – The balance will beep or show “PASS” once successful. – Remove the weight when done. Recheck Zero – Ensure the display returns to 0.000 g after removing the weight.

Tips:

Use certified weights for accuracy (Class F1 or E2).

Calibrate in a draft-free, vibration-free environment.

Calibrate daily or before critical measurements.

GSM Cutter & Balance

GSM Cutter

Brand: Schroder

Origin: Germany

Capacity: 100 Sq.cm

Supplied with 1 pcs cutting Pad and 04 pcs cutting blade.

Digital Electronics balance

Precision GSM Weight Balance 0.01g to 200g

Model: GSM200

Brand: Schroder

Origin: Germany

Related products

Hydraulic GSM Cutter

Hydraulic GSM Cutter

Hydraulic GSM Cutter

- High Cutting Precision - Ensures consistent and accurate fabric sample size for reliable GSM results.

- Effortless Operation- Hydraulic action reduces manual effort and operator fatigue.

- Ideal for Thick or Multi-Layer Fabrics - Cuts through dense or multiple fabric layers cleanly.

- Time-Saving - Speeds up the sample preparation process, especially for high-volume testing.

- Improves Test Accuracy - Uniform samples help eliminate errors in GSM calculation.

- Durable and Long-Lasting - Robust construction ensures stability and extended service life.

- Safety Enhancement - Reduces risk of injury compared to manual rotary cutters.

- Consistent Pressure Application - Hydraulic mechanism maintains steady force for each cut.

- Hydraulic Press Mechanism - Applies consistent and strong pressure for clean, even cuts.

- Standard Cutting Die (100 cm²) - Produces fabric samples suitable for GSM testing with standard area.

- Heavy-Duty Construction - Built with robust metal frame for long-term lab or industrial use.

- Sharp Stainless Steel Blades - Durable and replaceable blades ensure smooth, precise cuts.

- Cutting Pad Included - Comes with a rubber or nylon base to protect blades and ensure clean edges.

- Simple Lever or Button Operation - Easy to use with minimal training required.

- Non-slip Base - Provides stability during operation for safe, accurate cutting.

- Supports Various Fabric Types

- Place the Cutting Pad - Lay the rubber or nylon cutting pad on a flat surface.

- Position the Fabric - Place the fabric sample flat and smooth on the cutting pad.

- Align the Cutter - Position the GSM cutter die over the desired area of the fabric.

- Activate Hydraulic Press - Pull the lever or press the button to apply hydraulic pressure and cut the sample.

- Remove the Sample - Lift the cutter and carefully take out the circular fabric piece (usually 100 cm²).

- Weigh the Sample - Place the cut sample on a precision balance or GSM scale to determine weight.

- Calculate GSM - Multiply the sample weight (in grams) by 100 to get GSM.

Hydraulic GSM Cutter

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Tensile Strength tester

Spray Rating Tester

Spray Rating Tester

Spray Rating Tester

- Quick and Simple Evaluation - Offers a fast way to assess fabric water repellency without complex setup.

- Standardized Testing- Complies with AATCC 22 and ISO 4920, ensuring globally accepted results.

- Cost-Effective- Low maintenance and no power requirement make it economical for routine lab use.

- Improves Fabric Performance - Helps manufacturers develop or improve water-resistant textiles.

- Non-Destructive Test - Does not damage the fabric, allowing for additional tests on the same sample.

- Visual Grading- Easy to interpret using a standard spray rating chart (0 to 100 scale).

- Supports Quality Control - Detects finish degradation or variation in water-repellent treatments.

- Portable and Compact- Lightweight design allows easy use in various lab or field settings.

- Standardized Spray Nozzle - Delivers consistent water spray per AATCC and ISO specifications.

- 45° Specimen Mounting Angle - Ensures uniform test setup for accurate and repeatable results.

- Stainless Steel or Aluminum Frame - Corrosion-resistant and durable for long-term use with water exposure.

- Water Reservoir and Funnel System - Provides precise water volume (usually 250 ml) for each test.

- Graduated Spray Stand- Fixed height (150 mm above specimen) for controlled spray impact.

- Detachable Specimen Holder- Easy loading and removal of fabric samples.

- Compact and Lightweight Design - Portable and convenient for both lab and field testing.

- No Electricity Required - Fully manual operation increases reliability and reduces operating costs.

- Prepare the Sample - Cut fabric to standard size (usually 180 × 180 mm). - Condition the sample if required (21°C, 65% RH for 24 hours).

- Mount the Fabric - Place the fabric on the specimen holder at a 45° angle.

- Fill the Reservoir - Pour 250 ml of distilled water into the upper funnel.

- Start the Test - Release the water through the nozzle; it sprays over the fabric for about 25–30 seconds.

- Inspect the Fabric - After spraying, visually assess the water beading or penetration on the surface.

- Rate the Sample - Compare the fabric’s wetting pattern with the standard spray rating chart: - 100 = No sticking/wetting - 90–50 = Partial wetting - 0 = Complete wetting

- Record the Rating - Document the spray rating for quality control or reporting.

Spray Reting Tester

[Scope of application]:

Used for the determination of moisture resistance (wetting grade) of various fabrics

which have been or have not been treated with water resistance or water repellency.

[related standards]:

GB/T4745 ISO4920 AATCC22 JISL1092 etc.

[technical parameters]:

1. Glass funnel:150 x 150 (capacity 500ml)

2. Specimen placement angle:The level is 45 degrees.

3. Distance from nozzle to sample center:150mm

4. Specimen diameter:Ф150mm

5. Size of water receiving pan:500×400×30mm

6. Matching measuring cups:500ml

7, size 500 x 400 x 500mm

8. Instrument weight:5Kg

Spray Reting Tester

[Scope of application]:

Used for the determination of moisture resistance (wetting grade) of various fabrics

which have been or have not been treated with water resistance or water repellency.

[related standards]:

GB/T4745 ISO4920 AATCC22 JISL1092 etc.

[technical parameters]:

1. Glass funnel:150 x 150 (capacity 500ml)

2. Specimen placement angle:The level is 45 degrees.

3. Distance from nozzle to sample center:150mm

4. Specimen diameter:Ф150mm

5. Size of water receiving pan:500×400×30mm

6. Matching measuring cups:500ml

7, size 500 x 400 x 500mm

8. Instrument weight:5Kg Martindale abrasion tester Updated

Martindale abrasion tester updated

Latest Update 1 A+

- Clothing sample weight hammer:397±2g Furniture decoration sample weight hammer:597±2g C. Stainless steel discs:260±1g

- Effective friction diameter of grinding block: Type A 198g(3kpa) friction head 28.8-0.084mm Type B 155g(1.52N) friction head 90-0.10mm 6. Relative velocity of gripper and grinding table:50 + 2R / MI (20-70r / min adjustable) 7. Sampling hammer quality:2385±10g 8. Shape size:870×580×300mm 9. power supply:AC220V 50Hz 500W 10.Weight:73KG.

- [Standard accessories] Items and specifications Qty Notes Main machine 1Power cable 1A type 198g Friction head 9 B type 155g(1.52N) Friction head 9 597g Hammer 9 397g Hammer 9, 666666666 260g Stainless steel disc 9, 2385g Holding hammer 1,B Friction head felt 18 ¢90mm Steel ball 6, Rubber ring 18, Inner Hexagonal Wrench 1

- Sampler 1, Fuse 2 3A, Standard felt 18, Weight:750±50g/m2, Thickness:2.5±0.5mm, Standard foam lining 40, Density:0.03g/cm3,Thickness:3mm,Standard abrasive 9 Circular shear template Each φ140mm、φ38mm,Small screw knife 1, Bottom foot 4

Fabric drape tester

Fabric Drape Tester

Fabric Drape Tester is a lab device used to measure the drape ability of fabric—how it hangs under its own weight. It assesses how fabric conforms in folds or waves, which affects garment appearance and comfort. Purpose of Fabric Drape Tester: To evaluate the aesthetic and functional behavior of a fabric when suspended, especially important in apparel and home textiles. Working Principle: A circular fabric specimen is placed over a smaller disc. The unsupported edges drape downward. A light source casts a shadow of the draped shape onto a recording surface or scanner. The area of the shadow is measured to calculate the drape coefficient. Main Components of Fabric Drape Tester: - Rotating Support Disc: Holds the fabric. - Light Source: Projects the drape shadow. - Paper or Digital Scanner: Captures the drape outline. - Template: For cutting fabric to standard test size. - Software or Plan meter: Calculates the drape coefficient. Applications of Fabric Drape Tester: - Fashion and apparel design - Fabric development - Quality control in woven, knitted, or nonwoven fabrics Benefits of Fabric Drape Tester:- Quantifies Fabric Flow - Measures drape behavior accurately, crucial for garments and furnishings.

- Supports Design Decisions - Helps designers select fabrics that match the intended look and movement of a product.

- Improves Garment Fit and Comfort - Ensures fabrics behave naturally on the body, enhancing wear ability.

- Enhances Product Aesthetics - Prevents stiff or limp fabric choices in fashion, interior, or technical textiles.

- Standardized Evaluation - Enables comparison across fabrics using drape coefficient, based on standards (e.g., BS 5058).

- Supports R&D - Useful in developing new fabrics or finishes to improve drape quality.

- Non-Destructive Testing - Tests fabric without damaging it, allowing for further analysis.

- Boosts Quality Control - Identifies batch inconsistencies or performance issues early in production.

- Rotating Support Disc - Holds the fabric sample over a smaller disc to create natural drape.

- Standard Sample Size Support - Designed for circular fabric samples, usually 30 cm in diameter.

- Light Projection System - Projects the draped fabric’s shadow onto a screen or recording surface.

- Drape Coefficient Calculation - Measures the shadow area to compute the drape coefficient (percentage of unsupported area covered by the shadow).

- Digital or Manual Options - Available in models with digital image processing or manual plan meter tracing.

- Stable Base and Structure - Ensures consistent and vibration-free testing conditions.

- Sample Templates Provided - For cutting precise, standard-sized fabric specimens.

- User-Friendly Interface - Simple controls for rotation and light alignment.

- Compact and Lab-Ready Design - Fits easily on lab benches and in testing environments.

- Compliance with Testing Standards - Supports BS 5058 and other relevant drape measurement methods.

- Prepare the Fabric Sample - Cut a circular fabric sample, typically 30 cm in diameter, using the provided template.

- Place the Fabric - Center the fabric sample over the smaller support disc (usually 18 cm diameter) on the tester.

- Turn on the Light Source - Illuminate the fabric from above so it casts a shadow onto the recording surface or paper below.

- Capture the Shadow Outline - Trace the shadow manually on paper or capture it digitally, depending on the model.

- Measure the Shadow Area - Use a plan meter (manual) or software (digital) to determine the shadow’s area.

- Calculate Drape Coefficient (DC) - Use the formula:

- Record the Result - Log the drape coefficient to evaluate how stiff or flexible the fabric is.

- Repeat for Accuracy - Test multiple samples and average the results for consistency.

It is used for testing dynamic and static drape properties

(drape coefficient, shape change rate, surface ripple and drape uniformity, etc.)

of various fabrics.

Related standards GB/T23329 FZ/01045 BS5058 etc.

Instrument characteristics

1. CCD imaging, dynamic and static image processing.

2. A variety of charts and data statistics, analysis, storage, output

3. No need to replace background color, can test all kinds of color samples.

4. Work mode:Microcomputer control, CCD imaging, automatic processing of images and data automatically.

Technical parameters

1. Communication interface: RS232, USB

2. Image sensor: CCD sensor.

3. Static (dynamic) state draping coefficient: 0 ~ 100% + 2

4. Drapability uniformity: 0 ~ 100% + 2

5. The rate of morphological change is 0 to 100% + 2.

6. Surface waviness error: + 1

It is used for testing dynamic and static drape properties

(drape coefficient, shape change rate, surface ripple and drape uniformity, etc.)

of various fabrics.

Related standards GB/T23329 FZ/01045 BS5058 etc.

Instrument characteristics

1. CCD imaging, dynamic and static image processing.

2. A variety of charts and data statistics, analysis, storage, output

3. No need to replace background color, can test all kinds of color samples.

4. Work mode:Microcomputer control, CCD imaging, automatic processing of images and data automatically.

Technical parameters

1. Communication interface: RS232, USB

2. Image sensor: CCD sensor.

3. Static (dynamic) state draping coefficient: 0 ~ 100% + 2

4. Drapability uniformity: 0 ~ 100% + 2

5. The rate of morphological change is 0 to 100% + 2.

6. Surface waviness error: + 1 Bursting strength tester

Bursting strength tester

true burst

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

- Bursting pressure can reach up to 1.2MPa 5. The maximum burst and expansion degree can reach 70mm. 6. Strengthen the lighting system on the test surface. 7. The main aerodynamic force helps to clamp the sample system. 8. A variety of test areas are available, and the switching is easy.

- A variety of unit conversions between Chinese and English. 10. Reliable anti-pinch safety protection design. [Technical parameter]: 1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized) 2. The minimum graduation value: 0.0001Mpa 3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree pressurization.

Stretch Recovery Tester Static Method

Stretch Recovery Tester Static Method

Stretch Recovery Tester

- A sample is stretched to a predetermined extension or force.

- The stretch is maintained for a set period.

- After removing the load, the recovery (return to original length) is measured after a fixed time.

- The fabric sample is clamped and stretched to a specific length or force.

- It’s held for a fixed duration (e.g., 1–5 minutes).

- The tension is released, and the sample is allowed to recover.

- The recovered length is measured after a set time.

Stretch Recovery Tester

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated