Fabric flame retardant tester

$0.00

Fabric Flame Retardant Tester

A Fabric Flame Retardant Tester is a specialized laboratory instrument designed to evaluate the flammability characteristics of textiles. It assesses how fabrics react to direct flame exposure, measuring parameters such as ignition time, flame spread rate, after-flame duration, and afterglow time. This testing is crucial for ensuring that textiles meet safety standards for various applications, including apparel, home furnishings, and industrial uses.

Purpose and Applications

The primary purpose of a Fabric Flame Retardant Tester is to determine the flame resistance of textile materials. This is essential for:- Apparel Safety: Ensuring garments, especially children’s sleepwear and industrial work wear, meet flammability standards.

– Home Textiles: Testing curtains, drapes, upholstery, and bedding for fire safety compliance.

– Technical Textiles: Evaluating materials used in tents, protective clothing, and automotive interiors.

⚙️ Key Features

Modern Fabric Flame Retardant Testers incorporate several features to ensure accurate and reliable testing:- Adjustable Burner Angles: Allowing tests at various orientations (e.g., 0°, 45°, 90°) to simulate different real-world scenarios.

Automated Ignition Systems: Providing consistent flame application and reducing operator variability.

– Digital Timing Mechanisms: Accurately recording ignition time, flame spread, after-flame, and afterglow durations.

– Transparent Observation Windows: Enabling safe monitoring of the test without exposure to hazards.

– Compliance with International Standards: Meeting protocols such as ASTM D6413, ISO 6941, and EN ISO 15025 for standardized testing procedures.

Testing Standards

Fabric Flame Retardant Testers are designed to comply with various international standards, including:

– ASTM D6413: Standard Test Method for Flame Resistance of Textiles (Vertical Test).

– ISO 6941: Textiles — burning behavior — Measurement of flame spread properties of vertically oriented specimens.

– EN ISO 15025: Protective clothing — Protection against heat and flame — Method of test for limited flame spread.

️ How It Works

- Sample Preparation: A fabric specimen is cut to specified dimensions and conditioned as per standard requirements.

- Mounting: The sample is mounted vertically or at a specified angle in the testing chamber.

- Ignition: A controlled flame is applied to the fabric for a predetermined time.

- Observation: The tester records ignition time, flame spread, after-flame time, and afterglow time.

- Evaluation: Results are compared against standard criteria to determine compliance.

✅ Benefits

– Safety Assurance: Ensures textiles meet fire safety regulations, reducing risk in end-use applications.

– Quality Control: Identifies flammability issues during the manufacturing process.

– Regulatory Compliance: Helps manufacturers meet legal requirements for flammability.

– Product Development: Assists in developing flame-retardant materials for specialized applications.

For more detailed information on specific models and their features, you can refer to manufacturers like SDL Atlas’s Auto Flam Flammability Tester [1], TESTEX’s Vertical Flammability Chamber TF312

How to Use a Fabric Flame Retardant Tester (Vertical Flammability Test Method):

- Prepare the Sample

– Cut the fabric to standard dimensions (usually 300 × 75 mm).

– Condition the fabric for 24 hours at 21°C and 65% relative humidity.

- Mount the Sample

– Place the fabric vertically in the frame inside the test chamber.

– Ensure it’s held securely with no folds or slack.

- Set Up the Burner Position the burner at the required angle (usually 90° for vertical tests).

– Adjust flame size according to the standard (about 38 mm for ASTM D6413).

- Ignite the Flame – Apply the flame to the bottom edge of the fabric for 12 seconds.

- Observe and Measure – Start timing when flame is applied.

– Measure:

– After-flame time (how long it burns after flame removal)

– After-glow time (how long it glows after burning stops)

– Char length (distance burned vertically)

- Record the Results

– Repeat the test on multiple samples (usually 5) and calculate averages.

- Compare with Standards

– Evaluate whether the results meet the required flame resistance limits.

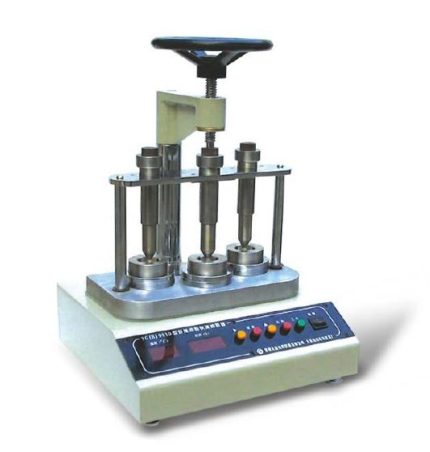

fabric flame retardant tester IV type (small 450 method)

Scope of application

It is used for testing the intensity and speed of

burning of flammable textile materials after ignition.

burning of flammable textile materials after ignition.

(specific ignition nozzles and sample holders can be customized to meet multiple criteria).

Related standards

GB/T14644 ASTM D1230 CFR1610 etc.

Technical parameters

1. The spread of time:0 ~ 999.9S resolution 0.1S

2. The temperature inside the box shows:Room temperature -99 degrees C resolution 1 c

3. Igniting time:1S

4. Type of igniter:4 1/2 syringe

5. Sample clip size:Outer frame:204mm * 78mm inner frame:152mm×38mm

6. Distance from the top of the igniter to the sample surface:8mm

7. Studio size and outline size

Studio size:370mm×220mm×350mm

Outline size:375mm×245mm×478mm

8. Power supply:AC220V 50Hz 20W

9. Weight:18Kg

Related products

Laboratory Padder

Laboratory Padder

A Laboratory Padder is a compact, laboratory-scale machine used to apply liquids like dyes, chemicals, and finishes to fabric samples. It simulates the padding process in textile manufacturing, where fabric is passed through a liquid solution, then squeezed between rollers to ensure uniform application and absorption. Key Features of a Laboratory Padder:- Adjustable Rollers - The fabric is passed through two or more rollers to apply even pressure and squeeze out excess solution, ensuring uniform chemical or dye application.

- Variable Pressure Control - Allows adjustment of roller pressure for different fabric types and chemical formulations, ensuring optimal penetration without damage.

- Solution Bath - Holds the liquid (e.g., dye, finish, or other chemical treatments) in a bath through which the fabric is dipped before passing through the rollers.

- Fabric Speed Control - Adjustable conveyor speed allows for control over the time the fabric spends in contact with the liquid solution, affecting the degree of treatment.

- Digital Control Panel - Provides easy adjustment of pressure, speed, and solution volume to ensure precise and reproducible results.

- Compact Design - Smaller, lab-scale version of industrial padders, ideal for research, development, and small-scale testing.

- Safety Features - Safety guards, emergency stops, and proper handling mechanisms to prevent accidents during operation.

- Precise Application of Chemicals - Provides uniform and controlled application of dyes, finishes, and other chemicals, ensuring consistent results.

- Small-Scale Testing - Ideal for small sample testing, allowing for fabric treatment without needing full-scale production equipment.

- Versatile Use - Suitable for dyeing, finishing, and applying various chemical treatments, making it a flexible tool for R&D labs.

- Cost-Effective - Reduces the need for large-scale machinery and the associated costs, while providing reliable results for small batches.

- Controlled Fabric Treatment - Offers adjustable pressure, speed, and solution concentration, enabling fine-tuned processing for different fabric types and applications.

- Accelerates Development - Speeds up the testing and development of new products or finishes, improving time-to-market for textile manufacturers.

- Energy Efficient - Consumes less energy compared to larger, industrial-scale machines, making it suitable for lab use.

- Compact and Space-Saving - Designed for laboratory environments with limited space, without compromising on functionality.

- Reproducible Results - Ensures consistent application of treatments across multiple samples, aiding in accurate testing and comparison.

- Adjustable Roller Pressure - Allows precise control over the pressure applied to the fabric, ensuring uniform chemical or dye application.

- Variable Speed Control - Adjustable conveyor speed for controlling the time the fabric spends in the solution bath, influencing the absorption rate.

- Solution Bath - Holds dye, chemicals, or finishes, and the fabric passes through this bath before moving to the rollers.

- Digital Control Panel - Easy-to-use interface for setting and adjusting parameters like speed, pressure, and solution concentration.

- Compact and Lab-Friendly Design - Designed for smaller, space-efficient use in textile labs, allowing for small sample testing.

- Roller Gap Adjustment - Allows for fine-tuning of the gap between rollers to regulate the amount of solution squeezed out of the fabric.

- Stainless Steel Construction - Durable and resistant to corrosion from the chemicals used in textile treatments.

- Safety Mechanisms - Includes safety guards, emergency stops, and user protection features during operation.

- Even and Controlled Application - Ensures even distribution of treatments (dye, finish, etc.) on fabric with minimal waste.

- Versatility in Application - Can be used for a wide range of textiles and treatments, including dyeing, softening, flame-retardant treatments, etc.

- Prepare the Fabric Sample - Cut the fabric sample to the required size for the experiment. Ensure it’s clean and free of any debris.

- Prepare the Solution - Mix the dye, chemical, or finish solution according to the desired concentration and the fabric's needs. Ensure that the solution is homogeneous.

- Set the Parameters - Pressure: Adjust the roller pressure based on the fabric type. Different fabrics require different pressure levels to ensure uniform application. - Speed: Set the fabric conveyor speed depending on the desired treatment time (longer exposure for deeper treatment).

- Load the Fabric into the Machine - Place the fabric carefully into the machine. The fabric should go through the solution bath and then pass between the rollers.

- Start the Machine - Turn on the machine and allow the fabric to pass through the rollers. The solution will be evenly applied to the fabric as it moves through the bath and is squeezed by the rollers.

- Monitor the Process - Keep an eye on the fabric to ensure it is being treated uniformly and there are no blockages or fabric jams.

- Unload the Fabric - Once the fabric has been treated, carefully remove it from the machine. Inspect for even application of the solution and any excess liquid.

- Dry or Process Further - Depending on the treatment, proceed with further steps such as drying, heat setting, or curing, as required by the experiment or process.

Mini Lab Dyeing Padder

Fabric air permeability tester

Fabric Air Permeability Tester

Fabric Air Permeability Tester is a lab instrument used to measure how easily air passes through a fabric. It quantifies the air permeability, which is crucial for evaluating breathability, comfort, and functional performance in textiles. Purpose Fabric Air Permeability Tester: It determines the rate of airflow through a fabric sample under a set air pressure, typically reported in units like cm³/cm²/s or L/m²/s. Working Principle: The tester creates a pressure difference across the fabric sample and measures the volume of air flowing through it. Higher air permeability means the fabric is more breathable. Main Components of Fabric Air Permeability Tester: - Test Head / Clamp: Holds the fabric securely without leakage. - Pressure Regulator: Maintains a constant air pressure during testing. - Flow Meter or Digital Sensor: Measures the actual airflow rate through the fabric. - Display Unit: Shows readings of air permeability instantly. Applications of Fabric Air Permeability Tester: - Performance textiles (sportswear, PPE) - Technical fabrics (filters, tents, airbags) - Medical textiles (masks, gowns) - Nonwovens and industrial materials Benefits of Fabric Air Permeability Tester:- Accurate Breathability Measurement - Precisely measures how breathable a fabric is, essential for comfort and performance.

- Supports Quality Control - Ensures consistent air permeability in fabric batches, critical for products like PPE, sportswear, and filters.

- Enhances Product Design - Helps in selecting or engineering fabrics with the right airflow properties for specific uses.

- Standard Compliance - Conforms to international testing standards (e.g., ASTM D737, ISO 9237), ensuring global credibility.

- Quick and Reliable Testing - Provides rapid results, increasing lab efficiency and production decision-making speed.

- Wide Material Compatibility - Suitable for woven, nonwoven, knitted fabrics, and even paper or coated materials.

- Improves Functional Performance - Helps optimize products for ventilation, moisture control, and thermal comfort.

- Reduces Product Failure - Identifies underperforming fabrics early, minimizing risks in high-performance applications.

- Digital Display - Shows air permeability readings clearly in units like L/m²/s or cm³/cm²/s.

- Precise Test Head/Clamp - Provides an airtight seal to prevent air leakage and ensure accurate results.

- Adjustable Pressure Settings - Allows testing under various pressure drops (e.g., 10–2500 Pa), depending on fabric type.

- Automatic Airflow Measurement - Built-in sensors or flow meters capture airflow rate automatically for quick analysis.

- Multiple Test Area Sizes - Interchangeable test plates to match different sample sizes and standard requirements.

- Data Logging and Export - Some models include USB or software connectivity for storing and exporting test results.

- Standard Compliance - Conforms to ASTM D737, ISO 9237, BS 5636, DIN 53887, etc.

- Robust Construction - Built with corrosion-resistant materials and durable components for long-term lab use.

- Low Maintenance - Simple cleaning and calibration process for reliable performance.

- Compact and User-Friendly Design - Ideal for lab benches and easy operation with minimal training.

- Prepare the Sample - Cut the fabric sample to the required size (usually circular, e.g., 20 cm²).

- Mount the Sample - Place the fabric securely in the test clamp or holder, ensuring no wrinkles or gaps.

- Set Test Parameters - Adjust the air pressure drop according to the fabric type or standard (e.g., 100 Pa).

- Start the Test - Turn on the air supply and start the airflow through the fabric.

- Read the Measurement - The digital display will show the air permeability value in the selected units.

- Record the Results - Note the readings or export data if the device supports it.

- Repeat if needed - Test multiple samples or areas for accuracy and average the results.

- Clean and Maintain - After testing, clean the clamp and ensure the device is calibrated regularly.

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm Fastness Rotary Friction Tester

Fastness Rotary Friction Tester

A Fastness Rotary Friction Tester, also known as a Rotary Crock meter, is a specialized instrument used to evaluate the color fastness of textiles and materials when subjected to rotational rubbing. This test simulates the wear and friction that fabrics experience during use, helping manufacturers assess the durability of dyes and finishes. Purpose of Fastness Rotary Friction Tester The primary function of the Fastness Rotary Friction Tester is to determine how well a fabric's color withstands rubbing, both in dry and wet conditions. This is crucial for ensuring the longevity and appearance of textiles in real-world applications, such as clothing, upholstery, and footwear. Working Principle of Fastness Rotary Friction Tester The tester operates by applying a specified pressure to a fabric sample using a standardized rubbing finger covered with a test cloth. The rubbing finger performs a set number of rotational movements (typically 1.125 turns clockwise followed by 1.125 turns counterclockwise) over the fabric surface. After the test, the degree of color transfer to the test cloth and any changes in the fabric's appearance are evaluated against standardized gray scales. Common Testing Standards - AATCC 116: Colorfastness to Crocking: Rotary Vertical Crock meter Method. ISO 105 X16: Textiles—Tests for color fastness—Part X16: Color fastness to rubbing—small areas. - SATRA TM8: Color fastness to rubbing. Key Specifications of Fastness Rotary Friction Tester - Rubbing Head Diameter: Typically 16 mm. - Applied Pressure: Approximately 1134 grams (11.1 N). - Rotation: 1.125 turns clockwise followed by 1.125 turns counterclockwise. - Sample Size: Commonly 60 mm × 60 mm. - Test Cloth: Standardized white cotton cloth, either dry or wetted depending on the test condition. Benefits of Fastness Rotary Friction Tester - Realistic Simulation: Mimics the actual wear and friction fabrics undergo during use. - Versatility: Applicable to a wide range of materials, including textiles, leather, and printed fabrics. - Quality Assurance: Ensures products meet industry standards for color durability. - Standard Compliance: Aligns with international testing standards, facilitating global trade and quality benchmarks. Applications Fastness Rotary Friction Tester - Textile Industry: Assessing the color durability of garments, upholstery, and other fabric products. - Footwear Manufacturing: Testing the colorfastness of shoe uppers and linings. - Automotive Interiors: Evaluating the wear resistance of seat covers and other interior fabrics. Quality Control Laboratories: Routine testing to ensure product consistency and compliance with standards. Benefits of Fastness Rotary Friction Tester:- Accurate Colorfastness Evaluation- Provides precise assessment of how well fabric resists color loss and staining from rubbing.

- Simulates Real-World Wear - Recreates rotational friction found in actual use (e.g., seat covers, apparel wear points).

- Supports Wet & Dry Testing - Can test under both dry and wet conditions for comprehensive results.

- Standardized Testing - Complies with global standards (AATCC 116, ISO 105 X16), ensuring reliable and comparable results.

- Time-Saving & Efficient - Quick to set up and run, allowing for high-throughput testing in labs.

- Versatile Use- Suitable for textiles, leather, coated fabrics, and printed surfaces.

- Improves Quality Control - Identifies potential durability issues early in the production process.

- Enhances Product Performance - Helps in developing fabrics with better resistance to rubbing and abrasion.

- Rotary Rubbing Mechanism - Simulates 1.125 clockwise and 1.125 counterclockwise turns for realistic friction.

- Standardized Rubbing Head - Fixed diameter (typically 16 mm) with specified pressure (≈1134 g) for consistent results.

- Dry and Wet Testing Capability - Can perform tests using dry or wet rubbing cloths.

- Sample Holder- Secure and easy-to-use fixture for holding fabric samples in place.

- Test Cloth Mounting Arm- Quick attachment for standardized white rubbing cloths.

- Simple Operation - Manual or motorized operation depending on model; easy to handle for lab technicians.

- Compliance with Standards - Follows AATCC 116, ISO 105 X16, and SATRA TM8 protocols.

- Prepare the Sample - Cut a fabric piece (typically 60 × 60 mm) and condition it per standard requirements.

- Mount the Fabric - Secure the fabric sample on the sample holder or base plate of the tester.

- Attach Rubbing Cloth - Place a standard white test cloth (dry or wetted as required) over the rubbing head.

- Apply Pressure - Lower the rubbing head onto the fabric. Standard weight is about 1134 g.

- Start the Test - Operate the tester: the head performs 1.125 turns clockwise, then 1.125 turns counterclockwise.- Number of cycles (typically 10 or 20) is set based on the test standard.

- Remove and Inspect - After testing, remove the rubbing cloth and assess any color transfer using a gray scale.

- Evaluate Fabric Surface - Check the fabric for visible changes, fading, or wear.

- Record Results - Grade both staining and fabric change per standard gray scale ratings.

It is used to change the color fastness of the textile,

printing and dyeing, printing and other products after a specific track friction.

[Related standards]

GB / T29865 AATCC116 ISO105-X16, etc.

[Instrument characteristics]:

1.Single-chip control, speed can be set freely

2.Imported motor, linear guide, low noise, suitable for long time work

3. Liquid crystal display, film panel

4. Freely set the number of friction, can count up and down,

and automatically stop the alarm when the set value is reached

[Technical Parameters]:

1. Friction head diameter: 16mm 25mm

2. Vertical pressure: 11.1N

3. Working mode: 405 ° clockwise and 405 ° counterclockwise

4. Speed range: constant 60 rpm, LCD display, thin mold panel

5. Counting range: 0-99999 times

6. Power supply: AC 220V 50Hz 80W

7. Weight: 20KG

8. Volume: L420mm × W260mm × H430mm

It is used to change the color fastness of the textile,

printing and dyeing, printing and other products after a specific track friction.

[Related standards]

GB / T29865 AATCC116 ISO105-X16, etc.

[Instrument characteristics]:

1.Single-chip control, speed can be set freely

2.Imported motor, linear guide, low noise, suitable for long time work

3. Liquid crystal display, film panel

4. Freely set the number of friction, can count up and down,

and automatically stop the alarm when the set value is reached

[Technical Parameters]:

1. Friction head diameter: 16mm 25mm

2. Vertical pressure: 11.1N

3. Working mode: 405 ° clockwise and 405 ° counterclockwise

4. Speed range: constant 60 rpm, LCD display, thin mold panel

5. Counting range: 0-99999 times

6. Power supply: AC 220V 50Hz 80W

7. Weight: 20KG

8. Volume: L420mm × W260mm × H430mm Oscillation type water bath Dyeing Machine

Oscillation Type Water Bath Dyeing Machine

An Oscillation Type Water Bath Dyeing Machine is a laboratory apparatus designed for dyeing and washing textile samples under controlled temperature conditions. It combines a heated water bath with an oscillating mechanism to ensure uniform dye penetration and consistent coloration across fabric or yarn samples. Key Features of Oscillation Type Water Bath Dyeing Machine - Oscillating Mechanism: Provides back-and-forth movement to agitate the dye solution, ensuring even contact between the dye and the textile sample.- Multiple Beaker Capacity: Typically accommodates 12 to 24 beakers, allowing simultaneous processing of multiple samples under identical or varied conditions. - Digital Temperature Control: Maintains precise temperature settings, usually up to 99°C, suitable for various dyeing processes including atmospheric dyeing, scouring, and bleaching.- Adjustable Oscillation Speed: Offers variable speed settings, commonly ranging from 50 to 200 cycles per minute, to accommodate different fabric types and dyeing requirements. - Programmable Settings: Advanced models come with programmable controllers, allowing users to set and save multiple dyeing protocols for repeatability and efficiency. Durable Construction: Constructed with high-quality stainless steel (e.g., SUS304), ensuring resistance to corrosion and longevity even under rigorous laboratory conditions. ✅ Benefits of Oscillation Type Water Bath Dyeing Machine - Uniform Dyeing Results: The oscillation mechanism ensures consistent dye penetration, reducing the risk of uneven coloration and enhancing the reproducibility of results.- Efficiency in Sample Processing: The ability to process multiple samples simultaneously accelerates laboratory workflows and facilitates comparative studies. - Versatility: Suitable for a range of applications including dyeing, washing, scouring, bleaching, and fastness testing across various textile materials.- Energy and Resource Conservation: Designed for low liquor ratios (e.g., 1:5 to 1:20), these machines minimize water and chemical usage, promoting sustainable laboratory practices. - Enhanced Safety and Cleanliness: Enclosed beaker systems reduce the risk of spills and exposure to chemicals, ensuring a safer laboratory environment. Typical Applications of Oscillation Type Water Bath Dyeing Machine - Textile Research and Development: Ideal for developing and testing new dye formulations and processes on a small scale before scaling up to production levels. Quality Control: Used in quality assurance laboratories to assess color fastness, dye uptake, and other critical parameters of textile products.- Educational Purposes: Serves as a practical tool in academic settings for teaching dyeing principles and techniques. In summary, the Oscillation Type Water Bath Dyeing Machine is an essential tool in textile laboratories, offering precise control over dyeing parameters, improving efficiency, and ensuring high-quality, reproducible results across various textile materials. Features of Oscillation Type Water Bath Dyeing Machine:- Oscillating Mechanism - Provides back-and-forth movement of beakers for uniform dye penetration and sample agitation.

- Multiple Beaker Capacity - Supports dyeing of 12–24 samples simultaneously, ideal for comparative lab testing.

- Digital Temperature Control - Maintains precise water bath temperature (typically up to 99°C), essential for consistent dyeing.

- Variable Oscillation Speed - Adjustable speed settings (e.g., 50–200 cycles/min) to suit different materials and processes.

- Programmable Settings - Allows setting of temperature, time, and speed for repeatable and automated dyeing cycles.

- Stainless Steel Construction - Corrosion-resistant frame and bath for durability in chemical environments.

- Beaker Safety Holders - Secure placement of beakers to prevent spills and maintain consistent treatment.

- Compact Design - Lab-friendly size for easy integration into research and quality control spaces.

- Low Liquor Ratio Operation - Efficient dyeing using minimal dye bath volume (e.g., 1:5 to 1:20), reducing chemical and water use.

- Quiet and Stable Performance

water bath/Shaker bath Dyeing machine

Fatigue tester for Elastic fabric

Fatigue Tester for Elastic Fabric

Fatigue tester for Elastic fabric

- Adjustable Stretch Range - Allows setting stretch levels (e.g., 0–100%) to simulate real-life fabric use.

- High-Cycle Capability - Supports up to millions of stretch-relax cycles for long-term fatigue analysis.

- Touch Screen Control - 7-inch color display for easy setup, monitoring, and data entry.

- Servo Motor Driven - Ensures precise and smooth linear motion during testing.

- Customizable Speed - Adjustable test speed (e.g., up to 40 cycles per minute) based on test requirements.

- Multi-Sample Testing - Some models allow testing multiple specimens simultaneously.

- Cycle Counter with Alarm - Built-in counter with programmable stop after preset cycles and auto-alert feature.

- Durable Construction - Robust metal frame suitable for continuous testing in lab environments.

- Standard Compliance - Designed to follow standards like GB/T 37635 for elastic fabric testing.

- Prepare the Sample

- Mount the Sample - Secure both ends of the fabric in the upper and lower clamps.

- Set Test Parameters

- Start the Test - Press start on the touch screen interface. - The machine will cyclically stretch and release the sample.

- Monitor Progress - Observe operation or let it run automatically.

- Remove and inspect - Take out the fabric and measure elongation, recovery, or visual defects.

- Record and Compare Results - Compare with initial measurements or standard performance criteria.

Fatigue tester for Elastic fabric

Fiber Oil Fast Extractor

Fiber Oil Fast Extractor

A Fiber Oil Fast Extractor is a laboratory instrument designed to determine the oil or finish content in fibers, yarns, or fabrics, particularly wool and synthetic materials. It operates on the principle of solvent extraction followed by evaporation. Working Principle of Fiber Oil Fast Extractor:- Sample Preparation: Cut the fabric or fiber into small pieces.

- Solvent Addition: Place the sample into a metal tube and add an appropriate solvent (e.g., petroleum ether, ethyl ether).

- Extraction: Apply weight to the sample to facilitate the dissolution of oils into the solvent.

- Evaporation: The solvent-oil mixture drips onto a heated plate where the solvent evaporates, leaving behind the oil.

- Measurement: Weigh the remaining oil and calculate its percentage relative to the initial sample mass.

- Accurate Oil Content Measurement- Precisely determines oil or finish content in fibers, crucial for quality control.

- Rapid Extraction Process - Delivers fast results, improving lab efficiency and productivity.

- Simultaneous Multi-Sample Testing - Multiple workstations (e.g., 4 at once) reduce testing time for bulk samples.

- Improved Product Quality - Helps maintain consistent oil levels, which affect dyeing, processing, and fabric performance.

- Automatic Operation - Automated pressing and heating reduce manual effort and operator error.

- Digital Monitoring - Built-in timer, temperature control, and oil calculator enhance accuracy and usability.

- Compliance with Standards - Supports industry methods like GB/T 6504-2017, ensuring reliable and standard-compliant results.

- Safe Solvent Handling - Enclosed design minimizes solvent exposure and evaporation loss.

- Multiple Test Stations - Usually equipped with 2 to 4 independent work units for parallel testing.

- Automatic Weight Pressing System - Applies consistent pressure on samples for uniform solvent extraction.

- Microcomputer Temperature Control - Maintains precise heating (typically 90–120°C) with ±1°C accuracy.

- Built-in Timer and Calculator - Allows setting extraction time and calculates oil content directly.

- Solvent Evaporation Plate- Heats and evaporates solvent quickly, leaving only the oil residue.

- Digital Display - Shows time, temperature, and process status for user-friendly operation.

- Compact and Durable Design - Made with corrosion-resistant materials suited for chemical handling.

- Safety Features - Includes overheat protection and enclosed solvent chamber to reduce exposure risk.

- Standard Compliant - Designed to meet GB/T 6504-2017 and similar industry testing standards.

- Prepare the Sample - Cut 5–10 g of fiber or yarn into small pieces and place in the sample tube.

- Add Solvent - Pour a suitable solvent (e.g., petroleum ether) into the tube to cover the sample.

- Apply Weight - Place the extractor's weight or press system onto the sample to aid extraction.

- Start Extraction - Activate the machine. The solvent dissolves the oils and flows to the heating plate.

- Heat for Evaporation - Set the temperature (typically 90–120°C). The solvent evaporates, leaving oil on the plate.

- Measure Oil Content- After drying, weigh the remaining oil. Use the built-in calculator or formula:

- Clean the Unit - After cooling, clean all parts to prepare for the next test.

Fiber Oil Fast Extractor

ICI Pilling & Snagging Test Machine

Stretch Recovery Tester Static Method

Stretch Recovery Tester Static Method

Stretch Recovery Tester

- A sample is stretched to a predetermined extension or force.

- The stretch is maintained for a set period.

- After removing the load, the recovery (return to original length) is measured after a fixed time.

- The fabric sample is clamped and stretched to a specific length or force.

- It’s held for a fixed duration (e.g., 1–5 minutes).

- The tension is released, and the sample is allowed to recover.

- The recovered length is measured after a set time.

Stretch Recovery Tester

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated