Digital thickness gauge

$0.00

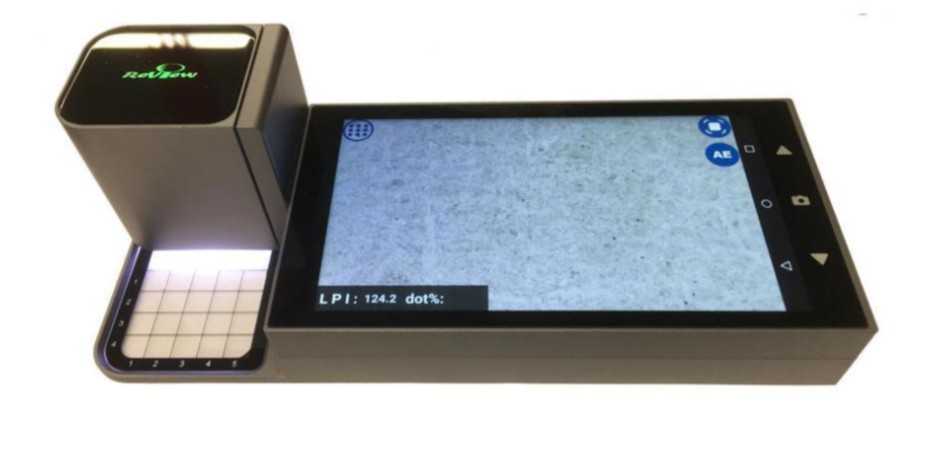

Digital Thickness Gauge

Digital Thickness Gauge

A Digital Thickness Gauge is a precision instrument used to measure the thickness of materials like fabric, paper, plastic, rubber, leather, and films. It displays readings digitally, offering greater accuracy, consistency, and ease of use compared to analog gauges.

Purpose of Digital Thickness Gauge:

– To measure material thickness accurately for quality control and specification compliance.

– Commonly used in textile, paper, packaging, plastic, and leather industries.

Working Principle of Digital Thickness Gauge:

– A flat presser foot is lowered onto the material placed on an anvil.

– The displacement between the anvil and foot is measured using a digital sensor.

– The value is displayed instantly on an LCD screen.

Key Features of Digital Thickness Gauge:

– Digital LCD Display – Clear, instant readings.

– High Accuracy & Resolution – Typically ±0.01 mm or better.

– Spring-Loaded Presser Foot – Applies uniform pressure.

– Zero Setting & Data Hold – For quick reference and repeatability.

– Unit Conversion – Switch between mm/inch.

– Battery Operated – Portable and convenient.

Applications of Digital Thickness Gauge:

– Fabric and textile labs

– Plastic film and paper mills

– Leather and rubber product inspection

– Research & development

Benefits of Digital Thickness Gauge:

- High Accuracy – Offers precise measurements, often up to ±0.01 mm, reducing human error.

- Quick Readout – Instant digital display of results speeds up testing and data collection.

- Easy to Use – Simple operation with one-button zeroing and unit conversion.

- Consistent Pressure Application – Spring-loaded foot ensures uniform pressure for repeatable results.

- Multi-Material Testing – Suitable for textiles, paper, film, rubber, leather, and nonwovens.

- Portable and Lightweight- Ideal for both lab and field use with battery-powered operation.

- Data Hold Function – Locks the measurement on-screen for easy recording.

- Improves Quality Control – Helps manufacturers maintain product thickness standards.

Features of Digital Thickness Gauge:

- Digital LCD Display – Provides clear, instant thickness readings in mm or inches.

- High Resolution & Accuracy – Typically measures with 0.01 mm precision.

- Spring-Loaded Presser Foot – Applies consistent pressure on samples for reliable results.

- Zero Setting Function- Allows quick reset before each measurement.

- Unit Conversion Button – Easily switch between metric (mm) and imperial (inch) units.

- Data Hold Function – Freezes the displayed value for easy recording.

- Portable Design – Compact and battery-operated for on-site or lab use.

- Durable Construction – Made from stainless steel or hardened materials for long life.

- Auto Power-Off – Saves battery by shutting off when idle.

- Variety of Anvil & Foot Sizes – Customizable based on testing standards or material types.

How to Use Digital Thickness Gauge:

- Power On the Device – Press the power button to turn on the gauge.

- Zero the Gauge – Close the anvil and presser foot fully. Press the “ZERO” button to reset the display to 0.00 mm.

- Select Unit (if needed) – Use the unit button to toggle between mm and inches.

- Place the Sample – Open the presser foot and insert the material between the foot and anvil.

- Apply Pressure – Gently release the presser foot to let it rest on the sample using its spring force.

- Read the Measurement- Read the thickness displayed on the LCD screen.

- Hold or Record the Data – Use the “HOLD” button (if available) to lock the reading for recording.

- Remove the Sample- Lift the presser foot and take out the material.

- Power Off – Turn off the device or let it auto shut-off.

- Features of Digital Thickness Gauge:

- Digital LCD Display – Provides clear, instant thickness readings in mm or inches.

- High Resolution & Accuracy – Typically measures with 0.01 mm precision.

- Spring-Loaded Presser Foot – Applies consistent pressure on samples for reliable results.

- Zero Setting Function- Allows quick reset before each measurement.

- Unit Conversion Button – Easily switch between metric (mm) and imperial (inch) units.

- Data Hold Function – Freezes the displayed value for easy recording.

- Portable Design – Compact and battery-operated for on-site or lab use.

- Durable Construction – Made from stainless steel or hardened materials for long life.

Related products

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Hydraulic GSM Cutter

Hydraulic GSM Cutter

Hydraulic GSM Cutter

- High Cutting Precision - Ensures consistent and accurate fabric sample size for reliable GSM results.

- Effortless Operation- Hydraulic action reduces manual effort and operator fatigue.

- Ideal for Thick or Multi-Layer Fabrics - Cuts through dense or multiple fabric layers cleanly.

- Time-Saving - Speeds up the sample preparation process, especially for high-volume testing.

- Improves Test Accuracy - Uniform samples help eliminate errors in GSM calculation.

- Durable and Long-Lasting - Robust construction ensures stability and extended service life.

- Safety Enhancement - Reduces risk of injury compared to manual rotary cutters.

- Consistent Pressure Application - Hydraulic mechanism maintains steady force for each cut.

- Hydraulic Press Mechanism - Applies consistent and strong pressure for clean, even cuts.

- Standard Cutting Die (100 cm²) - Produces fabric samples suitable for GSM testing with standard area.

- Heavy-Duty Construction - Built with robust metal frame for long-term lab or industrial use.

- Sharp Stainless Steel Blades - Durable and replaceable blades ensure smooth, precise cuts.

- Cutting Pad Included - Comes with a rubber or nylon base to protect blades and ensure clean edges.

- Simple Lever or Button Operation - Easy to use with minimal training required.

- Non-slip Base - Provides stability during operation for safe, accurate cutting.

- Supports Various Fabric Types

- Place the Cutting Pad - Lay the rubber or nylon cutting pad on a flat surface.

- Position the Fabric - Place the fabric sample flat and smooth on the cutting pad.

- Align the Cutter - Position the GSM cutter die over the desired area of the fabric.

- Activate Hydraulic Press - Pull the lever or press the button to apply hydraulic pressure and cut the sample.

- Remove the Sample - Lift the cutter and carefully take out the circular fabric piece (usually 100 cm²).

- Weigh the Sample - Place the cut sample on a precision balance or GSM scale to determine weight.

- Calculate GSM - Multiply the sample weight (in grams) by 100 to get GSM.

Hydraulic GSM Cutter

Digital Ink Rubbing Tester

Digital Ink Rubbing Tester

Digital Ink Rubbing Tester

Digital Ink Rubbing Tester

Pantone book

Pantone Book

Pantone Book

- Formula Guide (Solid Coated & Uncoated) – For spot color printing.

- Color Bridge – Shows Pantone spot colors alongside CMYK equivalents.

- Pantone Fashion, Home + Interiors (FHI) – For textiles, soft goods, and home decor.

- Pantone CMYK and Pastels & Neons Guides – For process printing and special effect colors.

- Formula Guide (Solid Coated & Uncoated)

- Color Bridge Guide (Coated & Uncoated)

- CMYK Guide (Coated & Uncoated)

- Pastels & Neons Guide

- Metallics Guide

- FHI Color Guide (TPG – Paper)

- FHI Cotton Passport & Cotton Planner (TCX – Textile)

- FHI Polyester Swatch Book

- Pantone SkinTone Guide

- Pantone Plastic Standard Chips

Pantone Book

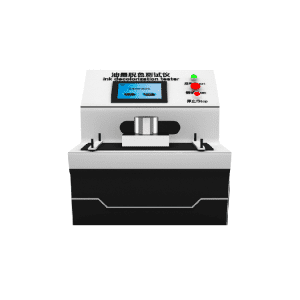

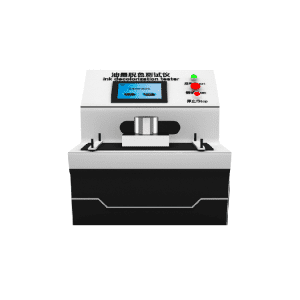

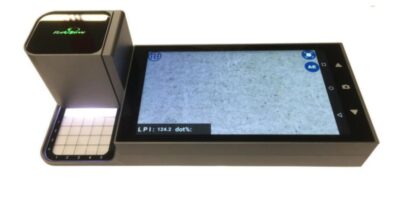

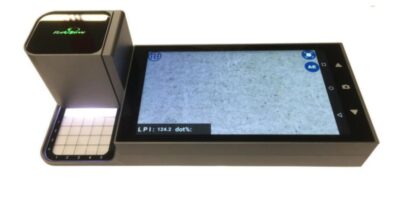

Digital Paper Dot Meter Densitometer

Digital Paper Dot Meter Densitometer

Digital Paper Dot Meter Densitometer

- Calibration: Performing white and black calibration using provided standards to ensure measurement accuracy.

- Sample Placement: Positioning the printed sample under the measurement aperture.

- Measurement: Initiating the measurement process via the touch screen or connected software.

- Data Analysis: Reviewing the displayed results and, if necessary, transferring data to a computer for further analysis.Regular calibration and maintenance are recommended to maintain the device's accuracy and longevity.

- Accurate Dot Analysis - Precisely measures dot gain, dot area, and enlargement for high-quality printing.

- Consistent Print Quality - Helps maintain uniform color density and contrast across print runs.

- Time-Saving - Quick digital readings eliminate the need for manual inspection and reduce errors.

- Multi-Parameter Testing - Measures density, color difference (ΔE), tone error, and gray balance in one device.

- Supports Industry Standards - Complies with ISO and other standards for print quality control.

- User-Friendly Interface - Touchscreen and onboard storage make it easy to operate and manage test data.

- Portable and Rechargeable - Battery-powered with thousands of readings per charge—ideal for field and lab use.

- Enhances Process Control - Enables precise adjustments during printing to reduce waste and reprints.

- High-Resolution CMOS Sensor - Ensures precise optical density and color measurements.

- Measurement Geometry: 45°/0° - Ideal for accurate reflection density readings on printed materials.

- Multiple Light Sources - Includes visible and UV LEDs for versatile testing conditions.

- Touchscreen Display - 3.5-inch color LCD with intuitive controls for easy operation.

- Multi-Function Measurement - Measures dot area, dot gain, density difference, tone error, and gray balance.

- Large Data Storage - Stores over 10,000 measurements for tracking and reporting.

- Rechargeable Battery - Long-lasting lithium battery supports up to 5,000 readings per charge.

- USB and Bluetooth Connectivity - Allows data transfer and remote operation via PC or mobile apps.

- Standard Compliance - Supports ISO Status A, E, I, T and CIE color spaces like LAB, LCh, XYZ.

- Multiple Observer Angles - Select between 2° and 10° for different visual perception simulations.

- Power On - Turn on the device using the power button.

- Calibrate - Perform black and white calibration using the provided standard tiles to ensure accuracy.

- Select Measurement Mode - Choose desired mode: density, dot area, dot gain, ΔE, contrast, or gray balance.

- Place Sample - Position the printed paper sample under the measurement aperture.

- Take Measurement - Press the measure button or tap the screen. The device will scan and display results instantly.

- Analyze Results - View data on the touchscreen. You can switch between values like density, dot area, and color difference.

- Save or Export Data - Store results in internal memory or transfer via USB/Bluetooth if needed.

- Power Off and Store - Turn off after use. Keep in a dust-free area to protect sensors.

Digital Paper Dot Meter Densitometer

Perspiration Tester

Perspiration Tester

Perspiration Tester

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Stainless Steel Frame - Corrosion-resistant body for durability and long-term use.

- Multi-Sample Capacity - Can hold up to 20 or more specimens for batch testing.

- Standardized Loading Weight- Applies uniform pressure (usually 12.5 kPa) across all samples.

- Removable Plates - Glass or acrylic plates ensure even contact and easy cleaning.

- Compact Design- Space-saving, bench-top model ideal for lab environments.

- Complies with Test Standards - Meets ISO 105 E04, AATCC 15, and related perspiration fastness standards.

- Ease of Operation - Simple loading, unloading, and incubation process.

- High-Temperature Resistance - Can be used inside incubators at 37°C or ovens as required.

- Prepare the Test Solution - Mix artificial acidic or alkaline perspiration as per standard (ISO or AATCC).

- Cut the Fabric Samples - Cut both the test fabric and adjacent white fabric (usually cotton) to standard size.

- Soak the Samples - Immerse the fabric sandwich (test + adjacent) in the test solution for 30 minutes.

- Remove Excess Liquid - Gently squeeze or blot to remove extra moisture—do not dry.

- Load in the Tester- Place each sandwich between glass or acrylic separator plates in the tester.

- Apply Pressure - Tighten the top plate or place the standard weight on top to apply uniform pressure.

- Incubate - Keep the loaded tester in an oven or incubator at 37°C for 4–16 hours (depending on the method).

- Accurate Sweat Simulation - Mimics real-life effects of acidic and alkaline perspiration on fabrics.

- Improves Product Quality - Ensures textiles retain color and don’t bleed or stain when worn.

- Supports Standard Compliance - Follows ISO and AATCC test standards for global market approval.

- Protects Brand Reputation- Reduces customer complaints due to dye transfer or fading.

- Simple and Repeatable- Provides consistent pressure and conditions for reliable results.

- Multi-Sample Testing- Tests multiple specimens at once, saving time in labs.

- Durable and Low Maintenance- Robust frame with minimal moving parts makes it long-lasting and easy to care for.

- Dry and Evaluate - Remove, air dry the samples, then assess color change and staining using a gray scale.

- Fabric samples are treated with synthetic perspiration solution (acidic or alkaline).

- They are sandwiched with adjacent fabric and placed between glass or acrylic plates.

- The assembly is loaded into the tester and pressed under specific pressure.

- it’s then incubated at 37°C (body temperature) for a fixed time (typically 4 or 16 hours).

- Afterward, color change and staining are evaluated using a gray scale.

Perspiration Tester

Analog Thickness Gauge

Analog Thickness Gauge

Analog Thickness Gauge

Brand : DUNLIN

Origin : TAIWAN Measuring Range : 0mm ~ 10mm

Accuracy : 0.01mm

Deep Throat Range : 120mm

Dimension : ( 195 × 130 × 25 ) mm

Benefits

High Durability – Since analog thickness gauges do not rely on electronic circuits, they are more durable and resistant to environmental factors such as dust and moisture.

No Power Requirement – These gauges operate mechanically, eliminating the need for batteries or power sources.

Cost-Effective – Analog meters are generally more affordable compared to digital alternatives while still providing precise measurements.

Ease of Use – Simple mechanical operation ensures that even non-technical users can easily measure thickness.

Reliable Performance – Analog thickness gauges provide consistent and accurate readings without the risk of software malfunctions.

Advantages

Immediate Readings – No waiting time for booting or calibration, providing instant measurement results.

Long-Lasting Accuracy – These devices do not suffer from battery drainage or electronic failures, ensuring accuracy over long periods.

Lightweight and Portable – Many analog thickness gauge meters are compact and easy to carry, making them convenient for on-the-go use.

Wide Material Compatibility – Suitable for measuring the thickness of metals, textiles, paper, and various industrial materials.

Minimal Maintenance – Without electronic parts, maintenance requirements are significantly reduced.

Applications

Manufacturing Industry – Used in quality control to ensure material thickness meets specified standards.

Automotive Sector – Helps measure paint and coating thickness on vehicles to ensure uniform application.

Metalworking and Fabrication – Used to measure sheet metal and pipe thickness to maintain precision in production.

Plastic and Rubber Industry – Ensures uniform thickness in plastic sheets, films, and rubber products.

Paper and Textile Industry – Essential for measuring paper thickness in printing industries and fabric thickness in textile production.

Aerospace and Aviation – Used for checking the thickness of coatings and composite materials in aircraft manufacturing.

Brand : DUNLIN

Origin : TAIWAN Measuring Range : 0mm ~ 10mm

Accuracy : 0.01mm

Deep Throat Range : 120mm

Dimension : ( 195 × 130 × 25 ) mm

Benefits

High Durability – Since analog thickness gauges do not rely on electronic circuits, they are more durable and resistant to environmental factors such as dust and moisture.

No Power Requirement – These gauges operate mechanically, eliminating the need for batteries or power sources.

Cost-Effective – Analog meters are generally more affordable compared to digital alternatives while still providing precise measurements.

Ease of Use – Simple mechanical operation ensures that even non-technical users can easily measure thickness.

Reliable Performance – Analog thickness gauges provide consistent and accurate readings without the risk of software malfunctions.

Advantages

Immediate Readings – No waiting time for booting or calibration, providing instant measurement results.

Long-Lasting Accuracy – These devices do not suffer from battery drainage or electronic failures, ensuring accuracy over long periods.

Lightweight and Portable – Many analog thickness gauge meters are compact and easy to carry, making them convenient for on-the-go use.

Wide Material Compatibility – Suitable for measuring the thickness of metals, textiles, paper, and various industrial materials.

Minimal Maintenance – Without electronic parts, maintenance requirements are significantly reduced.

Applications

Manufacturing Industry – Used in quality control to ensure material thickness meets specified standards.

Automotive Sector – Helps measure paint and coating thickness on vehicles to ensure uniform application.

Metalworking and Fabrication – Used to measure sheet metal and pipe thickness to maintain precision in production.

Plastic and Rubber Industry – Ensures uniform thickness in plastic sheets, films, and rubber products.

Paper and Textile Industry – Essential for measuring paper thickness in printing industries and fabric thickness in textile production.

Aerospace and Aviation – Used for checking the thickness of coatings and composite materials in aircraft manufacturing.

An Analog Thickness Gauge is a manual instrument used to measure the thickness of materials such as fabric, paper, leather, rubber, and plastic. Unlike digital gauges, it displays readings through a mechanical dial or scale.

Digital precision balance

digital precision balance

2/3/4/5 Digit Digital precision Balance

digital precision balance is a weight balance machine. It’s used to Low capacity balance. digital precision balance play an important role to accurate measurement. Digital precision balance is used to check weight paper, jewelry etc. It shows accurate result. We have the best collection of digital precision balance. MAAM TEX IS the best supplier of Precision Balance in Bangladesh

A Digital Precision Balance is a high-accuracy electronic weighing device used in laboratories, industries, and educational institutions for measuring mass with a high degree of precision. It is essential for tasks that require meticulous weight measurements, such as chemical analysis, formulation, and quality control. Key Features:- High Accuracy & Precision: - Typically offers readability from 0.1 g to 0.001 g (or even finer). - Ideal for weighing small amounts of material where accuracy is crucial.

- Digital Display: - Large, backlit LCD or LED display for easy reading. - Some models include touch screen interfaces.

- Tarring Function: - Allows you to subtract the weight of a container or packaging to get the net weight.

- Calibration: - Internal or external calibration to maintain accuracy over time. - Some advanced models have auto-calibration features.

- Weighing Units: - Supports multiple units like grams (g), milligrams (mg), carats (ct), and ounces (oz). Stable Platform: - Includes a draft shield to protect against air currents and vibrations, which can affect measurement accuracy.

- High Accuracy and Precision- Delivers extremely accurate weight measurements, often down to 0.001 g or better.- Crucial for experiments and applications where even slight variations can affect outcomes.

- User-Friendly Interface- Digital display makes readings easy to read and interpret.- Most models include intuitive controls for functions like tarring, unit conversion, and calibration.3. Speed and Efficiency- Provides instant, stable readings, saving time compared to manual or mechanical balances.- Streamlines lab workflows and enhances productivity.

- Versatile Applications- Suitable for various fields including chemistry, biology, pharmacology, food testing, and gemology.- Can handle diverse weighing tasks from solids to liquids and powders.

- Advanced Features- Tare Function: Subtracts the weight of containers automatically.- Multiple Weighing Units: Supports various measurement units.- Data Connectivity: Many models allow connection to computers or printers for data logging.

- Portability and Space Efficiency- Compact design fits easily in most laboratory setups.- Lightweight models are easy to move and store.

- Enhanced Safety and Reliability- Stable platform and draft shields reduce environmental interference.- Built-in calibration ensures ongoing accuracy.

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated