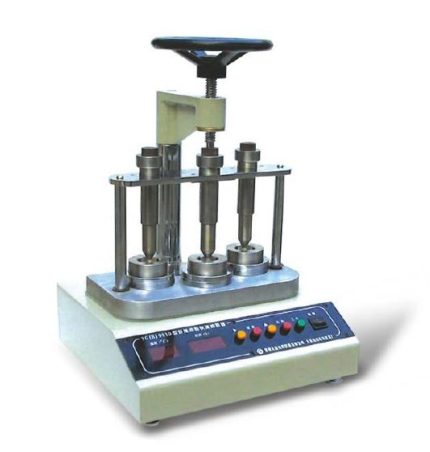

Fiber Oil Fast Extractor

Fiber Oil Fast Extractor

A Fiber Oil Fast Extractor is a laboratory instrument designed to determine the oil or finish content in fibers, yarns, or fabrics, particularly wool and synthetic materials. It operates on the principle of solvent extraction followed by evaporation. Working Principle of Fiber Oil Fast Extractor:- Sample Preparation: Cut the fabric or fiber into small pieces.

- Solvent Addition: Place the sample into a metal tube and add an appropriate solvent (e.g., petroleum ether, ethyl ether).

- Extraction: Apply weight to the sample to facilitate the dissolution of oils into the solvent.

- Evaporation: The solvent-oil mixture drips onto a heated plate where the solvent evaporates, leaving behind the oil.

- Measurement: Weigh the remaining oil and calculate its percentage relative to the initial sample mass.

- Accurate Oil Content Measurement- Precisely determines oil or finish content in fibers, crucial for quality control.

- Rapid Extraction Process - Delivers fast results, improving lab efficiency and productivity.

- Simultaneous Multi-Sample Testing - Multiple workstations (e.g., 4 at once) reduce testing time for bulk samples.

- Improved Product Quality - Helps maintain consistent oil levels, which affect dyeing, processing, and fabric performance.

- Automatic Operation - Automated pressing and heating reduce manual effort and operator error.

- Digital Monitoring - Built-in timer, temperature control, and oil calculator enhance accuracy and usability.

- Compliance with Standards - Supports industry methods like GB/T 6504-2017, ensuring reliable and standard-compliant results.

- Safe Solvent Handling - Enclosed design minimizes solvent exposure and evaporation loss.

- Multiple Test Stations - Usually equipped with 2 to 4 independent work units for parallel testing.

- Automatic Weight Pressing System - Applies consistent pressure on samples for uniform solvent extraction.

- Microcomputer Temperature Control - Maintains precise heating (typically 90–120°C) with ±1°C accuracy.

- Built-in Timer and Calculator - Allows setting extraction time and calculates oil content directly.

- Solvent Evaporation Plate- Heats and evaporates solvent quickly, leaving only the oil residue.

- Digital Display - Shows time, temperature, and process status for user-friendly operation.

- Compact and Durable Design - Made with corrosion-resistant materials suited for chemical handling.

- Safety Features - Includes overheat protection and enclosed solvent chamber to reduce exposure risk.

- Standard Compliant - Designed to meet GB/T 6504-2017 and similar industry testing standards.

- Prepare the Sample - Cut 5–10 g of fiber or yarn into small pieces and place in the sample tube.

- Add Solvent - Pour a suitable solvent (e.g., petroleum ether) into the tube to cover the sample.

- Apply Weight - Place the extractor's weight or press system onto the sample to aid extraction.

- Start Extraction - Activate the machine. The solvent dissolves the oils and flows to the heating plate.

- Heat for Evaporation - Set the temperature (typically 90–120°C). The solvent evaporates, leaving oil on the plate.

- Measure Oil Content- After drying, weigh the remaining oil. Use the built-in calculator or formula:

- Clean the Unit - After cooling, clean all parts to prepare for the next test.

Fiber Oil Fast Extractor

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated