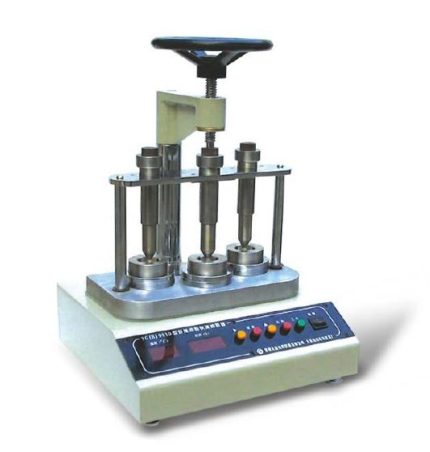

Bursting strength tester

$0.00

Bursting strength tester

true burst

Pneumatic bursting tester

China national patent:ZL201210486480.8 ZL201220628425.3

Pneumatic bursting strength tester

China national patent:ZL201210486480.8 ZL201220628425.3

[Scope of application]:

It is used to measure the burst strength and burst expansion degree of various fabrics,

including knitted fabrics, woven fabrics, non-woven fabrics, laminated fabrics and other

fabrics made by other processes, under standard conditions or wet conditions.

This method is employed to assess the burst strength and degree of burst expansion of various types of fabrics, such as knitted, woven, non-woven, laminated, and others produced through different processes, under both standard and wet conditions.

This technique is utilized to evaluate the burst strength and extent of burst expansion in various fabric types, including knitted, woven, non-woven, laminated, and others produced through diverse manufacturing processes, under both standard and wet conditions.

Benefits of Bursting strength tester:

Fast testing cycle for fast feedback to the production • Auto-start, a photocell detects the presence of a sample and automatically initiates a measurement sequence, thus allowing hands-free operation • Auto-cycling function permits the continuous cycling of the upper pressure foot to facilitate representative and continuous measurements

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

The sample is then quickly released and is ready for the next measurement at a new position. To maximize the sample measurement rate, the tester uses a minimum of time between the bursts, so that a series of 10 measurements can be done in less than 45 seconds. The actual measuring time depends of course on the type of paper or paper board being tested. Three

Different test results can be reported after a single measurement; bursting strength standard, bursting strength compensated, and bursting energy absorption (BEA).Bursting strength tester can be compensated for the stiffness of the diaphragm For low bursting strength levels, the stiffness of the diaphragm can account for a large portion of the bursting strength value. If desired, the device can also measure, calculate, and report effective bursting strength compensated from the effects of the diaphragm.

Measurement of Bursting Energy Absorption (BEA) is used to determine the energy absorption capability of a material. Strong, flexible paper has higher energy absorption values, while brittle, stiff paper has lower values. Bursting Strength Tester calculates and reports BEA according to the SCAN P 24 standard

Related standards of Bursting strength tester:

GB/T7742.2 (the first drafting unit of national standards) ISO13938-2, etc.

[Instrument characteristics]:

1. Microcomputer control, automatic burst test, automatic correction, automatic data

processing, and output results in the form of experimental report.

2. Aerodynamics, high cleanliness.

3. Color touch screen interface, Chinese and English menu operation, support online

communication.

- Bursting pressure can reach up to 1.2MPa

5. The maximum burst and expansion degree can reach 70mm.

6. Strengthen the lighting system on the test surface.

7. The main aerodynamic force helps to clamp the sample system.

8. A variety of test areas are available, and the switching is easy. - A variety of unit conversions between Chinese and English.

10. Reliable anti-pinch safety protection design.

[Technical parameter]:

1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized)

2. The minimum graduation value: 0.0001Mpa

3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree

pressurization.

4. Test accuracy: ≤±0.2%F·S

5. Thickness of elastic diaphragm: ≤2mm

6. Testing area: cm²) 100 50 10 7.3 Dia.φ(mm) φ112.8 φ79.8 φ35.7 φ30.5

7. Air pressure rate: non-linear segmented pressurization (0.1~0.5) L/min

8. Safety cover: high-transparent plexiglass

9. Power supply: AC220V±10% 50Hz 800W

10. Dimensions: (470×490×780)mm (host L×W×H)

Related products

Fabric Stiffness Tester

Fabric Stiffness Tester

Fabric Stiffness Tester is a lab instrument used to measure the stiffness or flexural rigidity of fabric materials. It evaluates how resistant a fabric is to bending, which influences its drape, comfort, and handling characteristics. Purpose of Fabric Stiffness Tester: To determine the stiffness of textiles by measuring the bending length and calculating flexural rigidity, often using methods like the Cantilever Test (as per ASTM D1388 or ISO 9073-7). Working Principle of Fabric Stiffness Tester: A fabric strip is slid over a horizontal platform until its free end bends under its own weight to a specific angle (usually 41.5°). The length at which this occurs is used to calculate bending length and stiffness. Main Components of Fabric Stiffness Tester: - Test Platform: Flat surface for sample movement. - Graduated Scale: Measures the overhanging length of fabric. - Angle Indicator: Guides the measurement based on standard deflection angle. - Fabric Clamp or Guide: Helps place and move the sample smoothly. Applications of Fabric Stiffness Tester: - Apparel fabrics (e.g., for comfort and drape analysis) - Technical textiles (e.g., automotive, medical fabrics) - Paper, nonwovens, and films Benefits of Fabric Stiffness Tester:- Accurate Measurement of Flexibility - Provides reliable data on fabric stiffness, essential for quality control and product development.

- Improves Product Comfort - Helps assess how soft or rigid a fabric will feel in clothing or furnishings.

- Supports Material Selection - Aids designers and engineers in choosing the right fabric for specific applications based on stiffness.

- Quality Assurance - Detects fabric inconsistencies or defects that affect handling or drape.

- Standards Compliance - Enables testing as per international standards like ASTM D1388 and ISO 9073-7 for global product approval.

- Quick and Simple Operation - Delivers fast results with minimal operator training or preparation.

- Applicable to Multiple Materials - Suitable for woven, nonwoven, knitted fabrics, paper, and films.

- Enhances R&D Accuracy - Supports consistent material testing during product innovation and textile finishing.

- Graduated Measurement Scale - Precise scale to measure overhang length for accurate stiffness calculation.

- Flat Test Platform - Smooth, level surface ensures consistent and reliable fabric movement.

- Standard Deflection Angle Guide - Built-in 41.5° angle reference for consistent stiffness testing (per ASTM/ISO).

- Manual or Motorized Models - Available in both types for simple or automated operation depending on lab needs.

- Compact Design - Space-saving unit ideal for textile labs and quality control rooms.

- Sample Holder or Clamp - Ensures correct alignment and smooth feeding of fabric strips during testing.

- Durable Construction - Made of corrosion-resistant materials like stainless steel or aluminum for long-term use.

- Compliance with Standards - Supports methods like ASTM D1388, ISO 9073-7 for stiffness testing of fabrics.

- Lightweight and Portable - Easy to move and use in various lab settings.

- Low Maintenance - Simple mechanical parts require minimal servicing.

- Prepare the Sample - Cut the fabric into a rectangular strip (e.g., 25 mm × 200 mm), as per standard.

- Place the Sample - Lay the fabric strip flat on the test platform with one end aligned at the zero mark.

- Slide the Fabric - Gently push the fabric forward so it slowly overhangs the platform.

- Watch for Deflection - Stop sliding when the free end of the fabric bends down to the reference angle (typically 41.5°).

- Read the Bending Length - Measure the overhang distance from the scale. This is the bending length (C).

- Calculate Flexural Rigidity

- Repeat for Accuracy - Test both warp and weft directions and average the results for better accuracy.

Scope of application

It is used to measure the stiffness of cotton,

wool, silk, linen, chemical fibers and other woven fabrics,

knitted fabrics, general nonwovens, coated fabrics, etc.

It is also suitable for measuring the stiffness of paper,

leather, film and other flexible materials.

Relevant Standards

GB/T 18318, ASTM D 1388, IS09073-7, BS EN22313 etc.

[Instrument Characteristics]

1. Infrared photoelectric invisible inclined plane

detection system replaces the traditional tangible inclined plane,

realizes non-contact detection, and overcomes the problem that

the measurement accuracy is affected by

the sample torsion lifted by the inclined plane.

2. The inclination adjustable mechanism of instrument

measurement to meet different test requirements.

3. Stepping motor drive, accurate measurement, smooth operation;

4. The color touch screen display can show the extended length,

bending length, bending stiffness of the sample, the warp average,

the weft average and the total average of the above values respectively.

5. Printing of Chinese report forms for thermal printers.

Technical parameters

1. Test methods: The two method (A method: Weft test, B method: Forward and backward test)

2. Measurement angle:41.5 degree, 43 degree and 45 degree adjustable

3. Extend the length range:5-220 mm (special requirements can be made at the time of ordering)

4. Length resolution:0.01mm

5. Measurement accuracy:±0.1mm

6. Specimen specifications:250×25mm

7. Work platform specifications:250×50mm

8. Specification of sample pressing plate:250×25mm

9. Pushing speed of press plate:3 mm/s; 4 mm/s; 5 mm/s

10. Display output: Touch screen display

11. Print Output: Chinese Report

12. Data Processing Volume: A total of 15 groups, each group less than 20 trials

13. Printer: Thermal printer

14, power supply:AC220V 50Hz

15. Host volume:570mm×360mm×490mm

16. Host weight:20kg

Scope of application

It is used to measure the stiffness of cotton,

wool, silk, linen, chemical fibers and other woven fabrics,

knitted fabrics, general nonwovens, coated fabrics, etc.

It is also suitable for measuring the stiffness of paper,

leather, film and other flexible materials.

Relevant Standards

GB/T 18318, ASTM D 1388, IS09073-7, BS EN22313 etc.

[Instrument Characteristics]

1. Infrared photoelectric invisible inclined plane

detection system replaces the traditional tangible inclined plane,

realizes non-contact detection, and overcomes the problem that

the measurement accuracy is affected by

the sample torsion lifted by the inclined plane.

2. The inclination adjustable mechanism of instrument

measurement to meet different test requirements.

3. Stepping motor drive, accurate measurement, smooth operation;

4. The color touch screen display can show the extended length,

bending length, bending stiffness of the sample, the warp average,

the weft average and the total average of the above values respectively.

5. Printing of Chinese report forms for thermal printers.

Technical parameters

1. Test methods: The two method (A method: Weft test, B method: Forward and backward test)

2. Measurement angle:41.5 degree, 43 degree and 45 degree adjustable

3. Extend the length range:5-220 mm (special requirements can be made at the time of ordering)

4. Length resolution:0.01mm

5. Measurement accuracy:±0.1mm

6. Specimen specifications:250×25mm

7. Work platform specifications:250×50mm

8. Specification of sample pressing plate:250×25mm

9. Pushing speed of press plate:3 mm/s; 4 mm/s; 5 mm/s

10. Display output: Touch screen display

11. Print Output: Chinese Report

12. Data Processing Volume: A total of 15 groups, each group less than 20 trials

13. Printer: Thermal printer

14, power supply:AC220V 50Hz

15. Host volume:570mm×360mm×490mm

16. Host weight:20kg Stretch Recovery Tester Static Method

Stretch Recovery Tester Static Method

Stretch Recovery Tester

- A sample is stretched to a predetermined extension or force.

- The stretch is maintained for a set period.

- After removing the load, the recovery (return to original length) is measured after a fixed time.

- The fabric sample is clamped and stretched to a specific length or force.

- It’s held for a fixed duration (e.g., 1–5 minutes).

- The tension is released, and the sample is allowed to recover.

- The recovered length is measured after a set time.

Stretch Recovery Tester

VeriVide Colour Assessment Cabinets

VeriVide Colour Assessment Cabinets

VeriVide offers high-quality Colour Assessment Cabinets (CACs) such as the CAC 60-4, CAC 60-5, and CAC 120-4&5. These cabinets, originating from the UK, are reliable tools for visual evaluation in quality assurance, meeting national, international, and retailer standards. They effectively mitigate issues related to color assessment.VeriVide Colour Assessment Cabinets

High-quality visual evaluation tool for quality assurance. Adhering to national, international and retailer standards.Colour Assessment Cabinet's (CACs) reduce problems associated with assessing products or samples in different environments,be though geological or seasonal, offering a cost-effective method to ensure visual accuracy and product quality.

Color Light Box Enhance color precision with VeriVide's cutting-edge Colour Assessment

Cabinets. These cabinets are meticulously designed to ensure accurate color evaluation in various industries. Invest in VeriVide Colour Assessment Cabinets to elevate your color assessment process.

Enhance Color Precision with VeriVide's Cutting-Edge Assessment Cabinets, which meet or surpass ISO 3664 and BS 950 Part 1 international standards. The cabinets are adaptable to user requirements, with lamp options to choose different light sources. Available in 60, 120, and 150cm widths, VeriVide Colour Assessment Cabinets provide a flexible solution for accurate color assessment.

Incorporate user-friendly features like servicing indicator, auto sequence, warm-up, power save and data storage.4 or 5 light source options Versions available for colour fastness testing and particulate testing both adhering to global standardsEnsure that you are using the best equipment available as they provide the best fluorescent D65 daylight simulator, with the highest Colour

Rendering Index (CRI), available. VeriVide Colour Assessment Cabinets products are known as light boxes, viewing booths, colour cabinets and others, depending on which industry or country they are serving in. They are used within a wide array of industry sectors throughout the world including textile and apparel, graphics, automotive, ceramics, cosmetics, pharmacology (CAC Particulate),

food, footwear, packaging and printing.Download the Datasheet below for more information or click 'VeriVide CAC Datasheet Here' to get in touch with colour experts.

VeriVide CAC Datasheet Here Features of VeriVide Colour Assessment Cabinets

• CAC 60, CAC 120 and CAC 150 accommodate 60, 120 and 150cm tubes respectively

VeriVide offers high-quality Colour Assessment Cabinets (CACs) such as the CAC 60-4, CAC 60-5, and CAC 120-4&5. These cabinets, originating from the UK, are reliable tools for visual evaluation in quality assurance, meeting national, international, and retailer standards. They effectively mitigate issues related to color assessment.VeriVide Colour Assessment Cabinets

High-quality visual evaluation tool for quality assurance. Adhering to national, international and retailer standards.Colour Assessment Cabinet's (CACs) reduce problems associated with assessing products or samples in different environments,be though geological or seasonal, offering a cost-effective method to ensure visual accuracy and product quality.

Color Light Box Enhance color precision with VeriVide's cutting-edge Colour Assessment

Cabinets. These cabinets are meticulously designed to ensure accurate color evaluation in various industries. Invest in VeriVide Colour Assessment Cabinets to elevate your color assessment process.

Enhance Color Precision with VeriVide's Cutting-Edge Assessment Cabinets, which meet or surpass ISO 3664 and BS 950 Part 1 international standards. The cabinets are adaptable to user requirements, with lamp options to choose different light sources. Available in 60, 120, and 150cm widths, VeriVide Colour Assessment Cabinets provide a flexible solution for accurate color assessment.

Incorporate user-friendly features like servicing indicator, auto sequence, warm-up, power save and data storage.4 or 5 light source options Versions available for colour fastness testing and particulate testing both adhering to global standardsEnsure that you are using the best equipment available as they provide the best fluorescent D65 daylight simulator, with the highest Colour

Rendering Index (CRI), available. VeriVide Colour Assessment Cabinets products are known as light boxes, viewing booths, colour cabinets and others, depending on which industry or country they are serving in. They are used within a wide array of industry sectors throughout the world including textile and apparel, graphics, automotive, ceramics, cosmetics, pharmacology (CAC Particulate),

food, footwear, packaging and printing.Download the Datasheet below for more information or click 'VeriVide CAC Datasheet Here' to get in touch with colour experts.

VeriVide CAC Datasheet Here Features of VeriVide Colour Assessment Cabinets

• CAC 60, CAC 120 and CAC 150 accommodate 60, 120 and 150cm tubes respectively

- Either 4 or 5 light sources available for each model including D65, D50, 840P15, F and UV - see Lamp Options.• Internal finishes in Munsell N5, Munsell N7 or Grey 5574 • Diffuser and/or dimmer options available Dimensions of VeriVide Colour Assessment Cabinets CAC 60-4 Dimensions (mm) Width Height Depth Overall 710 545 420

Digital hot plate-magnetic stirrer

Digital hot plate-magnetic stirrer

Digital hot plate-magnetic stirrer

- Magnetic Stirrer:

- Digital Display and Controls:

- Temperature Sensors: - Built-in or external probes (like a PT100 or thermocouple) for accurate temperature control.

- Precision and Control- Digital Interface: Allows accurate setting and monitoring of temperature and stirring speed.- Consistent Results: Ensures reproducibility in experiments and solution preparations.

- Efficient Mixing and Heating- Uniform Mixing: Magnetic stirring eliminates hotspots and ensures even distribution of solutes.- Simultaneous Operation: Ability to heat and stir at the same time improves efficiency.

- Safety Features- Overheat Protection: Prevents accidents by automatically shutting off at unsafe temperatures.- Sealed Surface: Reduces risk of contamination and easy to clean.

- Versatility

- Compact and User-Friendly- Takes up minimal bench space.- Simple to operate with user-friendly controls and displays.

- Durability- High-quality materials like ceramic or stainless steel tops resist corrosion and wear.

- Time-Saving Speeds up preparation of solutions and reactions compared to manual stirring and separate heating. Would you like these benefits presented in a slide format or for a product brochure?

Oscillation type water bath Dyeing Machine

Oscillation Type Water Bath Dyeing Machine

An Oscillation Type Water Bath Dyeing Machine is a laboratory apparatus designed for dyeing and washing textile samples under controlled temperature conditions. It combines a heated water bath with an oscillating mechanism to ensure uniform dye penetration and consistent coloration across fabric or yarn samples. Key Features of Oscillation Type Water Bath Dyeing Machine - Oscillating Mechanism: Provides back-and-forth movement to agitate the dye solution, ensuring even contact between the dye and the textile sample.- Multiple Beaker Capacity: Typically accommodates 12 to 24 beakers, allowing simultaneous processing of multiple samples under identical or varied conditions. - Digital Temperature Control: Maintains precise temperature settings, usually up to 99°C, suitable for various dyeing processes including atmospheric dyeing, scouring, and bleaching.- Adjustable Oscillation Speed: Offers variable speed settings, commonly ranging from 50 to 200 cycles per minute, to accommodate different fabric types and dyeing requirements. - Programmable Settings: Advanced models come with programmable controllers, allowing users to set and save multiple dyeing protocols for repeatability and efficiency. Durable Construction: Constructed with high-quality stainless steel (e.g., SUS304), ensuring resistance to corrosion and longevity even under rigorous laboratory conditions. ✅ Benefits of Oscillation Type Water Bath Dyeing Machine - Uniform Dyeing Results: The oscillation mechanism ensures consistent dye penetration, reducing the risk of uneven coloration and enhancing the reproducibility of results.- Efficiency in Sample Processing: The ability to process multiple samples simultaneously accelerates laboratory workflows and facilitates comparative studies. - Versatility: Suitable for a range of applications including dyeing, washing, scouring, bleaching, and fastness testing across various textile materials.- Energy and Resource Conservation: Designed for low liquor ratios (e.g., 1:5 to 1:20), these machines minimize water and chemical usage, promoting sustainable laboratory practices. - Enhanced Safety and Cleanliness: Enclosed beaker systems reduce the risk of spills and exposure to chemicals, ensuring a safer laboratory environment. Typical Applications of Oscillation Type Water Bath Dyeing Machine - Textile Research and Development: Ideal for developing and testing new dye formulations and processes on a small scale before scaling up to production levels. Quality Control: Used in quality assurance laboratories to assess color fastness, dye uptake, and other critical parameters of textile products.- Educational Purposes: Serves as a practical tool in academic settings for teaching dyeing principles and techniques. In summary, the Oscillation Type Water Bath Dyeing Machine is an essential tool in textile laboratories, offering precise control over dyeing parameters, improving efficiency, and ensuring high-quality, reproducible results across various textile materials. Features of Oscillation Type Water Bath Dyeing Machine:- Oscillating Mechanism - Provides back-and-forth movement of beakers for uniform dye penetration and sample agitation.

- Multiple Beaker Capacity - Supports dyeing of 12–24 samples simultaneously, ideal for comparative lab testing.

- Digital Temperature Control - Maintains precise water bath temperature (typically up to 99°C), essential for consistent dyeing.

- Variable Oscillation Speed - Adjustable speed settings (e.g., 50–200 cycles/min) to suit different materials and processes.

- Programmable Settings - Allows setting of temperature, time, and speed for repeatable and automated dyeing cycles.

- Stainless Steel Construction - Corrosion-resistant frame and bath for durability in chemical environments.

- Beaker Safety Holders - Secure placement of beakers to prevent spills and maintain consistent treatment.

- Compact Design - Lab-friendly size for easy integration into research and quality control spaces.

- Low Liquor Ratio Operation - Efficient dyeing using minimal dye bath volume (e.g., 1:5 to 1:20), reducing chemical and water use.

- Quiet and Stable Performance

water bath/Shaker bath Dyeing machine

Fiber Oil Fast Extractor

Fiber Oil Fast Extractor

A Fiber Oil Fast Extractor is a laboratory instrument designed to determine the oil or finish content in fibers, yarns, or fabrics, particularly wool and synthetic materials. It operates on the principle of solvent extraction followed by evaporation. Working Principle of Fiber Oil Fast Extractor:- Sample Preparation: Cut the fabric or fiber into small pieces.

- Solvent Addition: Place the sample into a metal tube and add an appropriate solvent (e.g., petroleum ether, ethyl ether).

- Extraction: Apply weight to the sample to facilitate the dissolution of oils into the solvent.

- Evaporation: The solvent-oil mixture drips onto a heated plate where the solvent evaporates, leaving behind the oil.

- Measurement: Weigh the remaining oil and calculate its percentage relative to the initial sample mass.

- Accurate Oil Content Measurement- Precisely determines oil or finish content in fibers, crucial for quality control.

- Rapid Extraction Process - Delivers fast results, improving lab efficiency and productivity.

- Simultaneous Multi-Sample Testing - Multiple workstations (e.g., 4 at once) reduce testing time for bulk samples.

- Improved Product Quality - Helps maintain consistent oil levels, which affect dyeing, processing, and fabric performance.

- Automatic Operation - Automated pressing and heating reduce manual effort and operator error.

- Digital Monitoring - Built-in timer, temperature control, and oil calculator enhance accuracy and usability.

- Compliance with Standards - Supports industry methods like GB/T 6504-2017, ensuring reliable and standard-compliant results.

- Safe Solvent Handling - Enclosed design minimizes solvent exposure and evaporation loss.

- Multiple Test Stations - Usually equipped with 2 to 4 independent work units for parallel testing.

- Automatic Weight Pressing System - Applies consistent pressure on samples for uniform solvent extraction.

- Microcomputer Temperature Control - Maintains precise heating (typically 90–120°C) with ±1°C accuracy.

- Built-in Timer and Calculator - Allows setting extraction time and calculates oil content directly.

- Solvent Evaporation Plate- Heats and evaporates solvent quickly, leaving only the oil residue.

- Digital Display - Shows time, temperature, and process status for user-friendly operation.

- Compact and Durable Design - Made with corrosion-resistant materials suited for chemical handling.

- Safety Features - Includes overheat protection and enclosed solvent chamber to reduce exposure risk.

- Standard Compliant - Designed to meet GB/T 6504-2017 and similar industry testing standards.

- Prepare the Sample - Cut 5–10 g of fiber or yarn into small pieces and place in the sample tube.

- Add Solvent - Pour a suitable solvent (e.g., petroleum ether) into the tube to cover the sample.

- Apply Weight - Place the extractor's weight or press system onto the sample to aid extraction.

- Start Extraction - Activate the machine. The solvent dissolves the oils and flows to the heating plate.

- Heat for Evaporation - Set the temperature (typically 90–120°C). The solvent evaporates, leaving oil on the plate.

- Measure Oil Content- After drying, weigh the remaining oil. Use the built-in calculator or formula:

- Clean the Unit - After cooling, clean all parts to prepare for the next test.

Fiber Oil Fast Extractor

ICI Pilling & Snagging Test Machine

HTHP Glycerin bath dyeing machine

HTHP Glycerin Bath Dyeing Machine

HTHP dyeing machine

- High Temperature Capability - Operates up to 140°C or more, ideal for disperse dyeing of polyester which requires elevated temperatures.

- Glycerin as Heat Transfer Medium - Glycerin allows for precise and uniform heating beyond the boiling point of water, without pressure buildup as in steam-based systems.

- Small Sample Dyeing - Used for lab-scale dyeing of fabric or yarn samples (commonly 5–10 g per tube), useful in R&D or color matching.

- Multiple Sample Capacity - Usually has multiple dyeing tubes/chambers for simultaneous dyeing of several samples under identical conditions.

- Accurate Temperature and Time Control - Digital or microprocessor-based controllers regulate temperature, heating rate, and timing precisely.

- Uniform Dyeing - Ensures even dye penetration due to consistent heat distribution and controlled rotation or agitation.

- Energy Efficient Glycerin’s heat retention reduces energy consumption compared to steam systems.

- Compact and Durable Design - Bench-top design, made from stainless steel and heat-resistant components for long life and lab use.

- Uniform Heating with Glycerin - Glycerin provides consistent heat transfer, ensuring even dye uptake and minimizing shade variation.

- Energy Efficient- Glycerin retains heat longer, reducing energy consumption compared to traditional steam-based dyeing.

- Accurate Process Control - Precise temperature and time control enhance reproducibility and dyeing consistency.

- Ideal for Lab and Sample Work - Perfect for R&D, shade matching, and recipe development with small fabric or yarn samples.

- Multi-Sample Dyeing - Allows multiple samples to be dyed simultaneously under identical conditions, saving time and effort.

- Compact and Safe - Bench-top design fits in laboratories and is safer than high-pressure steam systems.

- Low Maintenance - Simplified operation and fewer mechanical parts compared to steam-based systems lower upkeep needs.

- Faster Dyeing Cycles- Glycerin heats and cools quickly, reducing overall dyeing time.

- High-Temperature Operation - Capable of dyeing up to 140–150°C, suitable for synthetic fibers like polyester.

- Glycerin as Heat Medium - Uses glycerin for uniform, efficient heat transfer without generating high steam pressure.

- Multiple Dyeing Chambers - Usually equipped with 6–24 tubes for simultaneous multi-sample dyeing under identical conditions.

- Digital Temperature Controller- Offers precise control of temperature, time, and heating rate with programmable settings.

- Compact and Lab-Friendly Design - Bench-top model, easy to operate in laboratory environments with limited space.

- Stainless Steel Construction - Corrosion-resistant and durable for long-term, high-temperature operation.

- Safety Features - Includes over-temperature protection and thermal insulation to prevent heat loss and ensure operator safety.

- Agitation or Sample Rotation- Some models offer rotation or agitation for uniform dye penetration.

- Energy Efficient Heating - Glycerin’s heat retention improves energy efficiency over water- or steam-based systems.

- Low Maintenance - Simplified mechanical system reduces the need for frequent servicing.

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated