Xenon Arc Light Fastness Tester

Xenon Arc Light Fastness Tester is a laboratory instrument used to evaluate the color fastness of textiles and materials when exposed to sunlight or artificial light. It simulates full-spectrum sunlight using a xenon arc lamp, making it ideal for assessing how materials resist fading over time.

Purpose of Xenon Arc Light Fastness Tester:

To determine how well a fabric or material maintains its color and integrity under prolonged light exposure, especially for outdoor or light-sensitive applications.

Working Principle of Xenon Arc Light Fastness Tester :

A xenon arc lamp emits light similar to natural sunlight. Fabric samples are exposed under controlled temperature, humidity, and light intensity. The degree of fading is compared to standard blue wool scales to assign a light fastness rating.

Main Components Xenon Arc Light Fastness Tester :

– Xenon Arc Lamp: Simulates sunlight (UV, visible, and infrared).

– Sample Holder: Rotates samples for uniform exposure.

– Environmental Controls: Maintains specific temperature and humidity.

– Control Panel/Software: Sets test parameters (light, time, humidity, etc.).

– Filters: Control the light spectrum (e.g., daylight, window glass).

Applications:

– Textiles

– Automotive interiors

– Plastics, paints, and coatings

– Outdoor fabrics and furnishings

Benefits of Xenon Arc Light Fastness Tester:

- Realistic Sunlight Simulation – Accurately mimics full-spectrum natural sunlight, including UV, for reliable light fastness testing.

- Standard Compliance – Meets international standards like ISO 105-B02, AATCC TM16, and ASTM G155, ensuring globally accepted results.

- Improves Product Durability – Helps manufacturers assess and improve resistance to color fading, cracking, or degradation from light exposure.

- Versatile Applications – Suitable for testing textiles, plastics, paints, leather, and coatings.

- Controlled Test Conditions – Offers precise control over temperature, humidity, and light intensity, improving test consistency and repeatability.

- Supports Quality Assurance – Detects early failures in colorfastness, enabling better product design and material selection.

- Automated Operation – Programmable tests and automatic monitoring reduce operator involvement and errors.

- Accelerated Testing – Speeds up evaluation by simulating months or years of sun exposure in a few days or weeks.

Features of Xenon Arc Light Fastness Tester:

- Xenon Arc Lamp – Provides full-spectrum light (UV, visible, IR) to simulate natural sunlight accurately.

- Programmable Control System – Digital or touchscreen interface for setting test parameters like exposure time, temperature, humidity, and irradiance.

- Humidity and Temperature Control – Maintains precise environmental conditions inside the test chamber.

- Rotating Sample Carousel – Ensures uniform light exposure on all test specimens.

- Light Spectrum Filters- Adjustable filters simulate different light conditions (e.g., daylight, window glass, outdoor).

- Standards Compliance- Meets ISO, AATCC, ASTM, and other global test methods for light fastness.

- Automatic Irradiance Control – Maintains constant light intensity throughout testing, improving accuracy.

- Safety Features – Includes overheating protection, door interlock, and lamp monitoring system.

- Data Logging and Export – Some models offer USB or software integration for saving and analyzing test data.

- Durable and Insulated Chamber – Built with high-quality materials for stable testing and long-term use.

How to Use Xenon Arc Light Fastness Tester:

- Prepare the Samples

– Cut fabric or material into standard-size specimens.

– Label and condition samples (usually 24 hrs at 21°C, 65% RH).

- Mount the Samples – Attach samples onto holders or clips, placing them evenly on the rotating drum or carousel.

- Insert Blue Wool Standards- Include standard blue wool reference fabrics to compare light fastness.

- Set Test Parameters

– Use the control panel to set:

– Irradiance (e.g., 0.35 W/m² at 420 nm)

– Temperature and humidity

– Test duration (e.g., 24–72 hrs or more)

- Start the Test – Close the chamber door and begin the exposure cycle.

- Monitor Progress- System auto-adjusts irradiance and logs test conditions. Periodically check if needed.

- End and Remove Samples – After completion, stop the test and remove the samples and blue wool references.

- Evaluate Results – Compare the sample fading to the blue wool scale to assign a light fastness rating (1–8 scale).

Xenon Arc Light Fastness Tester

[Scope of application]

It is used for the light fastness and weather fastness test in the color fastness test. It

can also be used for the light fastness test and light fastness test of paints,

pigments, coatings, rubber, plastics, wood floors, paper and other materials. Aging

test.

Related Standards of Xenon Arc Light Fastness Tester

GB/T8427 (China National Standard Drafting Unit)

GB/T15102-2006 GB/T14576 GB/T15104-2006 GB/T8430 AATCC TM16 ISO105-B04

ISO105-B02 etc.

Instrument characteristics of Xenon Arc Light Fastness Tester

1. Digital setting of light intensity, real-time monitoring, and automatic adjustment

to meet the stability requirements of different standards for test light sources

(420nm can be switched; 300-800nm or 300-400nm band monitoring);

2. Standard Blackboard Thermometer (BST) and Blackboard Thermometer (BPT)

can be selected for use, and are tested at the same station (equal distance) as the

sample, which truly reflects the tested condition of the sample;

3. The measured data is processed by the CPU and displayed on the color screen in

the form of numbers, graphs, curves, etc., without stopping for observation;

4. Microchip’s 32-bit intelligent CPU, high-efficiency real-time control, to ensure

accurate reproduction of the same test environment;

5. 7-inch color screen display and control, multiple test monitoring modes

(animation, numbers, charts), convenient control, intuitive and clear;

6. All sample holders can be timed separately, and different samples can be tested

on the same machine, which is convenient for test monitoring and reduces

operating costs;

7. Rated 1500W long arc xenon lamp technology, high efficiency and energy saving,

real simulation of sunlight spectrum;

8. Industrial temperature control (refrigeration) system, rapid and stable

temperature adjustment in the test chamber;

9. Built-in self-circulation system and air filtration system, greatly reducing

environmental requirements;

10. European traceable spectrum analyzer, multi-measurement calibration;

11. Built-in network communication module, can customize the remote monitoring

function of mobile phone APP;

12. The instrument can be optionally equipped with thermal printout or data

export of test environment parameters;

13. The quality assurance that one test can run continuously for 1000 hours

[Technical Parameters]1. Temperature control range of test chamber: (20~50)℃; accuracy: ±2℃

2. Test chamber humidity control range: (15~95)%RH, accuracy: ±5%RH

3. Test time control range: 0~9999:59 (h:min); accuracy: ±1min

4. Irradiance control range:

(0.80~1.60)W/m2/420nm Accuracy: ±0.02W/m2/420nm

(25-60)W/m2/300-400nm Accuracy: ±2W/m2/420nm

(300-650)W/m2/300-800nm Accuracy: ±10W/m2/420nm

Digital setting, automatic compensation

Xenon light source:

a. Rated power of xenon arc lamp: 1.5kW;

b. Color temperature: 5500K~6500K;

6. Sample:

a. Rotation speed of sample holder: 5rpm

b. Diameter of sample holder distribution: 286mm

c. The size and number of sample holders that can be installed:

GB standards AATCC(Optional)

Specimen clamp size

203mm×

48mm

220mm×92mm

Maximum sample size

135mm×

45mm

150mm×90mm

Maximum exposure area

118mm×

33mm

130mm×50mm

Maximum number of

pieces

13

6

d. Timing of each sample holder separately: range: 0~9999:59 (h: min); accuracy: ±

1min

e. Sample thickness: ≤3mm

7. Standard Blackboard Thermometer (BST) range:

(20~75)℃; Resolution: 0.1℃, Accuracy: ±2℃

Or optional blackboard temperature (BPT) range:

(25~80)℃, resolution: 0.1℃, accuracy: ±2℃

8.7 inch touch screen operation

9. Stand-alone with thermal printer (optional)

10. Power supply: AC220V±10% 50Hz 3.5kW

11. Dimensions: 1130mm×760mm×1895mm

12.Weight: about 380kg

(Note: The equipment test conforms to the standard based on the above basic

configuration and parameters. If it involves other standards and the test exceeds

the above technical content, please contact our company for special

customization)

(Note: The equipment test conforms to the standard based on the above basic

configuration and parameters. If it involves other standards and the test exceeds

the above technical content, please contact our company for special

customization)

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated

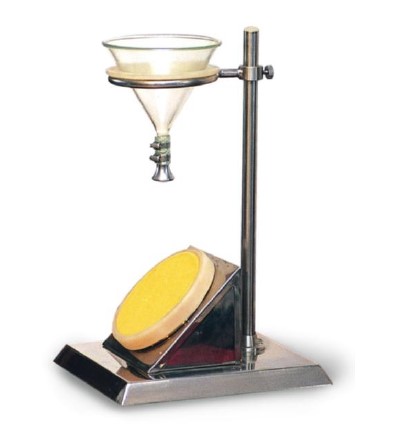

It is used for testing dynamic and static drape properties

(drape coefficient, shape change rate, surface ripple and drape uniformity, etc.)

of various fabrics.

Related standards GB/T23329 FZ/01045 BS5058 etc.

Instrument characteristics

1. CCD imaging, dynamic and static image processing.

2. A variety of charts and data statistics, analysis, storage, output

3. No need to replace background color, can test all kinds of color samples.

4. Work mode:Microcomputer control, CCD imaging, automatic processing of images and data automatically.

Technical parameters

1. Communication interface: RS232, USB

2. Image sensor: CCD sensor.

3. Static (dynamic) state draping coefficient: 0 ~ 100% + 2

4. Drapability uniformity: 0 ~ 100% + 2

5. The rate of morphological change is 0 to 100% + 2.

6. Surface waviness error: + 1

It is used for testing dynamic and static drape properties

(drape coefficient, shape change rate, surface ripple and drape uniformity, etc.)

of various fabrics.

Related standards GB/T23329 FZ/01045 BS5058 etc.

Instrument characteristics

1. CCD imaging, dynamic and static image processing.

2. A variety of charts and data statistics, analysis, storage, output

3. No need to replace background color, can test all kinds of color samples.

4. Work mode:Microcomputer control, CCD imaging, automatic processing of images and data automatically.

Technical parameters

1. Communication interface: RS232, USB

2. Image sensor: CCD sensor.

3. Static (dynamic) state draping coefficient: 0 ~ 100% + 2

4. Drapability uniformity: 0 ~ 100% + 2

5. The rate of morphological change is 0 to 100% + 2.

6. Surface waviness error: + 1

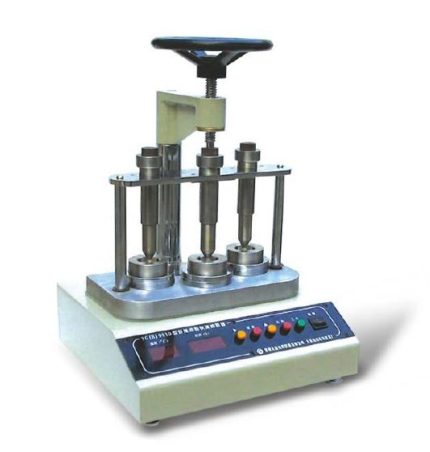

Scope of application

It is used to determine the moisture permeability of various fabrics

(including moisture permeable coated fabrics)

and nonwovens such as batting cotton and space cotton.

[Related standards] GB/T12704 ASTM E90 JIS L1099A BS 7209 JIS L1099B (custom) etc.

Instrument characteristics

1. Integrated structure of baking oven and constant temperature and humidity box.

2. Microcomputer control, color touch screen Chinese menu operation.

3. Circulating air velocity 0.2-3m/s digital setting.

4. Imported high-precision temperature and humidity sensor, imported motor drive, ceramic

heating tube heating.

Technical parameters

1.Work mode: Microcomputer control, color touch screen Chinese menu operation, test environment monitoring.

2. Sample box control temperature:15 ~ 40 C, accuracy 0.1 + C, resolution 0.01 C

3. Heat dissipation mode:Air cooling

4. Sample box control humidity:30 ~ 95%, precision + 2%, resolution 0.01%

5. Test chamber humidification:≥300ml/h

6. Accompany oven control temperature: Room temperature to 200 c

7. Test time:1min~999h59min

8. The rate of circulating steam flow:0. 2-3m/s digital setting resolution 0.01m/s

9. Moisture permeability area:2827㎜2(∮60㎜GB)

Optional 3848, 2 (70 70 ASTM)

10. The number of moisture permeable cups.6 (GB) can be replaced by 6 (US standard).

11. Internal dimensions of drying oven:490×400×215mm

12. Power supply:Ac220V 50Hz 6kw

13. Size:930×820×1700mm

14. Weight:350kg

Scope of application

It is used to determine the moisture permeability of various fabrics

(including moisture permeable coated fabrics)

and nonwovens such as batting cotton and space cotton.

[Related standards] GB/T12704 ASTM E90 JIS L1099A BS 7209 JIS L1099B (custom) etc.

Instrument characteristics

1. Integrated structure of baking oven and constant temperature and humidity box.

2. Microcomputer control, color touch screen Chinese menu operation.

3. Circulating air velocity 0.2-3m/s digital setting.

4. Imported high-precision temperature and humidity sensor, imported motor drive, ceramic

heating tube heating.

Technical parameters

1.Work mode: Microcomputer control, color touch screen Chinese menu operation, test environment monitoring.

2. Sample box control temperature:15 ~ 40 C, accuracy 0.1 + C, resolution 0.01 C

3. Heat dissipation mode:Air cooling

4. Sample box control humidity:30 ~ 95%, precision + 2%, resolution 0.01%

5. Test chamber humidification:≥300ml/h

6. Accompany oven control temperature: Room temperature to 200 c

7. Test time:1min~999h59min

8. The rate of circulating steam flow:0. 2-3m/s digital setting resolution 0.01m/s

9. Moisture permeability area:2827㎜2(∮60㎜GB)

Optional 3848, 2 (70 70 ASTM)

10. The number of moisture permeable cups.6 (GB) can be replaced by 6 (US standard).

11. Internal dimensions of drying oven:490×400×215mm

12. Power supply:Ac220V 50Hz 6kw

13. Size:930×820×1700mm

14. Weight:350kg