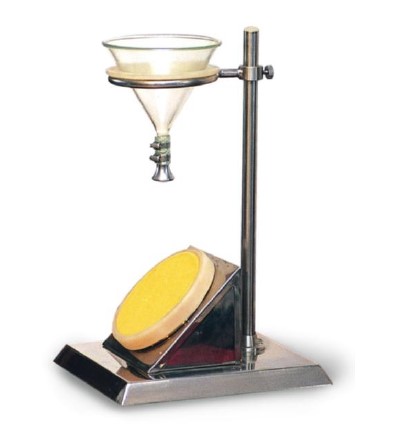

Spray Rating Tester

Spray Rating Tester

The Spray Rating Tester is a textile testing instrument used to evaluate the water resistance or water repellency of fabric surfaces. It measures how well a fabric can resist wetting when exposed to a controlled spray of water, helping assess its performance in rain or damp conditions.

Purpose of Spray Rating Tester

– To assess surface wetting resistance of textiles.

– Commonly used for outdoor clothing, rainwear, tents, and performance fabrics.

Working Principle of Spray Rating Tester

– A fabric specimen is mounted at a 45° angle.

– Water is sprayed from a standard nozzle for a specific time.

– After spraying, the fabric is visually rated based on the appearance of water drops and wetting.

Key Components of Spray Rating Tester

– Spray Nozzle: Delivers a consistent, standard water spray.

– Funnel & Reservoir: Controls the flow and volume of water.

– Specimen Holder: Positions the fabric at a 45° angle.

– Spray Stand: Ensures accurate nozzle height and positioning.

Standards Used of Spray Rating Tester

– AATCC 22

– ISO 4920

– BS EN 24920

Applications of Spray Rating Tester

– Rainwear and water-resistant textiles.

– Quality control in fabric finishing.

– R&D for performance apparel.

Benefits of Spray Rating Tester:

- Quick and Simple Evaluation – Offers a fast way to assess fabric water repellency without complex setup.

- Standardized Testing- Complies with AATCC 22 and ISO 4920, ensuring globally accepted results.

- Cost-Effective- Low maintenance and no power requirement make it economical for routine lab use.

- Improves Fabric Performance – Helps manufacturers develop or improve water-resistant textiles.

- Non-Destructive Test – Does not damage the fabric, allowing for additional tests on the same sample.

- Visual Grading- Easy to interpret using a standard spray rating chart (0 to 100 scale).

- Supports Quality Control – Detects finish degradation or variation in water-repellent treatments.

- Portable and Compact- Lightweight design allows easy use in various lab or field settings.

Features of Spray Rating Tester:

- Standardized Spray Nozzle – Delivers consistent water spray per AATCC and ISO specifications.

- 45° Specimen Mounting Angle – Ensures uniform test setup for accurate and repeatable results.

- Stainless Steel or Aluminum Frame – Corrosion-resistant and durable for long-term use with water exposure.

- Water Reservoir and Funnel System – Provides precise water volume (usually 250 ml) for each test.

- Graduated Spray Stand- Fixed height (150 mm above specimen) for controlled spray impact.

- Detachable Specimen Holder- Easy loading and removal of fabric samples.

- Compact and Lightweight Design – Portable and convenient for both lab and field testing.

- No Electricity Required – Fully manual operation increases reliability and reduces operating costs.

How to Use Spray Rating Tester:

- Prepare the Sample – Cut fabric to standard size (usually 180 × 180 mm). – Condition the sample if required (21°C, 65% RH for 24 hours).

- Mount the Fabric – Place the fabric on the specimen holder at a 45° angle.

- Fill the Reservoir – Pour 250 ml of distilled water into the upper funnel.

- Start the Test – Release the water through the nozzle; it sprays over the fabric for about 25–30 seconds.

- Inspect the Fabric – After spraying, visually assess the water beading or penetration on the surface.

- Rate the Sample – Compare the fabric’s wetting pattern with the standard spray rating chart: – 100 = No sticking/wetting – 90–50 = Partial wetting – 0 = Complete wetting

- Record the Rating – Document the spray rating for quality control or reporting.

Spray Rating Tester,

Water Repellency Tester

Spray Reting Tester

[Scope of application]:

Used for the determination of moisture resistance (wetting grade) of various fabrics

which have been or have not been treated with water resistance or water repellency.

[related standards]:

GB/T4745 ISO4920 AATCC22 JISL1092 etc.

[technical parameters]:

1. Glass funnel:150 x 150 (capacity 500ml)

2. Specimen placement angle:The level is 45 degrees.

3. Distance from nozzle to sample center:150mm

4. Specimen diameter:Ф150mm

5. Size of water receiving pan:500×400×30mm

6. Matching measuring cups:500ml

7, size 500 x 400 x 500mm

8. Instrument weight:5Kg

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated

burning of flammable textile materials after ignition.

(specific ignition nozzles and sample holders can be customized to meet multiple criteria).

Related standards

GB/T14644 ASTM D1230 CFR1610 etc.

Technical parameters

1. The spread of time:0 ~ 999.9S resolution 0.1S

2. The temperature inside the box shows:Room temperature -99 degrees C resolution 1 c

3. Igniting time:1S

4. Type of igniter:4 1/2 syringe

5. Sample clip size:Outer frame:204mm * 78mm inner frame:152mm×38mm

6. Distance from the top of the igniter to the sample surface:8mm

7. Studio size and outline size

Studio size:370mm×220mm×350mm

Outline size:375mm×245mm×478mm

8. Power supply:AC220V 50Hz 20W

9. Weight:18Kg

burning of flammable textile materials after ignition.

(specific ignition nozzles and sample holders can be customized to meet multiple criteria).

Related standards

GB/T14644 ASTM D1230 CFR1610 etc.

Technical parameters

1. The spread of time:0 ~ 999.9S resolution 0.1S

2. The temperature inside the box shows:Room temperature -99 degrees C resolution 1 c

3. Igniting time:1S

4. Type of igniter:4 1/2 syringe

5. Sample clip size:Outer frame:204mm * 78mm inner frame:152mm×38mm

6. Distance from the top of the igniter to the sample surface:8mm

7. Studio size and outline size

Studio size:370mm×220mm×350mm

Outline size:375mm×245mm×478mm

8. Power supply:AC220V 50Hz 20W

9. Weight:18Kg

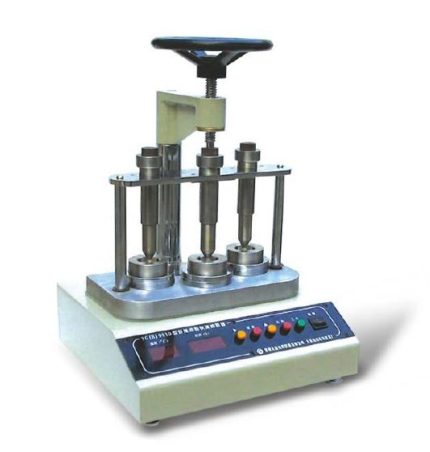

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.)

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.)

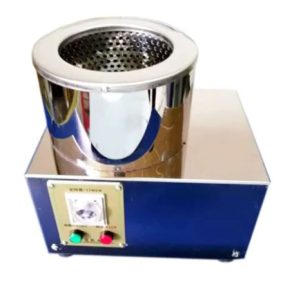

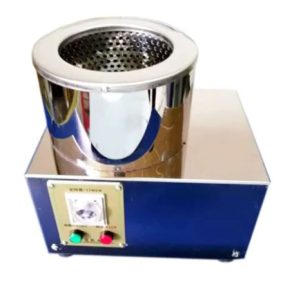

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min

Brad: DUNLIN

Origin: China

Application scope of small dehydrator:

This dehydrator is a kind of small sample dehydration

experimental equipment with micro capacity

Parameter specification:

Inner barrel size: 185mm in diameter * 80Hmm

Outer barrel size: ∮200*125Hmm

Overall dimension: 290 * 220* 295Hmm

Power supply: single phase 220 V / 50 Hz power: 60 W speed: 1800 R / min