Martindale abrasion tester Updated

$0.00

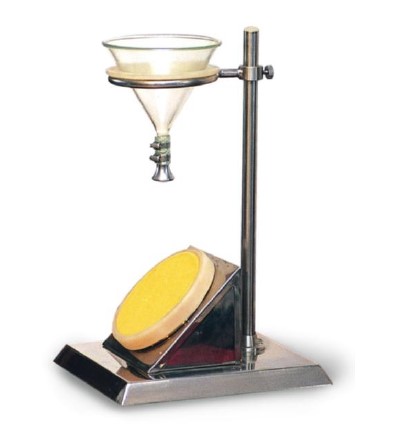

Martindale abrasion tester updated

Latest Update 1 A+

Martindale Wear-Resistant Instrument

Martindale Wear-Resistant Instrument

Martindale abrasion tester updated purposefully designed to enhance the ease of use and reliability of results Strong and solid base feet to increase instrument stability Sliding pad design reduces noise of motion plate.

Martindale abrasion tester updated Accessible Motion plate storage rack incorporated into the side of the instrument to conserve lab space and allowing full access to all abrasion stations Enhanced sample holders allowing for quicker sample loading Quick-lock couplers facilitate easy access for service and calibration

Martindale abrasion tester updated is a versatile instrument capable of multiple abrasion and pilling tests. It uses precision components to deliver the exact abrasion or pilling movement required by all international and retailer standards. Martindale abrasion tester updated Full Color Touch Screen Controls Most common functions accessible in one or two touches Displays individual station counters Test materials ordering information accessible directly on the instrument display Multi-lingual interface with display options in English, Chinese.

Martindale abrasion tester updated Designed for Adaptability the Martindale Line can perform a variety of abrasion and pilling tests. The user-friendly design allows operators to easily change over testing station configurations with specialized enhancement kits.

Martindale abrasion tester updated can be used for: Fabric Abrasion, Fabric Pilling, Sock, Abrasion, Leather Abrasion, Edge Abrasion, Testing Floor Coverings, Toothbrush Testing’s, Other Specialized Testing’s,

Martindale abrasion tester updated Convenient The compact base is designed to conserve valuable lab space while providing maximum testing capacity. Two sizes available: Larger base can have 4, 6, or 9 test positions Instrument Comes Standard with: Sample Holders 9 kPa and 12 kPa Weights for standard abrasion testing Standard Mounting Device

Martindale abrasion tester updated have Accessory Holder Available separately to conveniently hold martindale accessories while not in use Made from high quality acrylic and designed to be both practical and attractive Quality Test Materials supplies a wide variety of consumables design specifically for testing on the Martindale Abrasion and Pilling Tester.

These high quality consumables will ensure that each test performed is accurate and reliable. Martindale abrasion tester updated Scope of application Its is used for testing the wear resistance, abrasion and appearance change (pilling) of textiles and membrane materials (Martindale method).

Martindale abrasion tester updated Related standard

GB/T 21196 (International Standard Drafting Unit), FZ/T 20020, GB/T 4802.2, GB/T 13775,

ASTM D4966, ASTM D4970, ASTM D3886, ISO 12945.2, ISO 12947, JIS L1096, IWSTM

196/TM112 M&S, etc.

[Instrumentation characteristics]

1. Three test modes, adding and subtracting two counting modes.

2. No turning guide plate design, no need to move the sample.

3. PLC modular control, seven inch color touch screen, Chinese and English double-choice menu operation.

[Technical parameters]

1. Workplace:9 place 666665555

2. Counting range:0-999999 times

3. Maximum travel:60.5±0.5mm 24±0.5mm

4. Pressure mass:

- Clothing sample weight hammer:397±2g

Furniture decoration sample weight hammer:597±2g

C. Stainless steel discs:260±1g - Effective friction diameter of grinding block: Type A 198g(3kpa) friction head 28.8-0.084mm Type B 155g(1.52N) friction head 90-0.10mm

6. Relative velocity of gripper and grinding table:50 + 2R / MI (20-70r / min adjustable)

7. Sampling hammer quality:2385±10g 8. Shape size:870×580×300mm 9. power supply:AC220V 50Hz 500W 10.Weight:73KG. - [Standard accessories]

Items and specifications Qty Notes Main machine 1Power cable 1A type 198g Friction head 9 B type 155g(1.52N) Friction head 9 597g Hammer 9 397g Hammer 9, 666666666

260g Stainless steel disc 9, 2385g Holding hammer 1,B Friction head felt 18 ¢90mm

Steel ball 6, Rubber ring 18, Inner Hexagonal Wrench 1 - Sampler 1, Fuse 2 3A, Standard felt 18, Weight:750±50g/m2, Thickness:2.5±0.5mm, Standard foam lining 40, Density:0.03g/cm3,Thickness:3mm,Standard abrasive 9

Circular shear template Each φ140mm、φ38mm,Small screw knife 1, Bottom foot 4

Related products

Fatigue tester for Elastic fabric

Fatigue Tester for Elastic Fabric

Fatigue tester for Elastic fabric

- Adjustable Stretch Range - Allows setting stretch levels (e.g., 0–100%) to simulate real-life fabric use.

- High-Cycle Capability - Supports up to millions of stretch-relax cycles for long-term fatigue analysis.

- Touch Screen Control - 7-inch color display for easy setup, monitoring, and data entry.

- Servo Motor Driven - Ensures precise and smooth linear motion during testing.

- Customizable Speed - Adjustable test speed (e.g., up to 40 cycles per minute) based on test requirements.

- Multi-Sample Testing - Some models allow testing multiple specimens simultaneously.

- Cycle Counter with Alarm - Built-in counter with programmable stop after preset cycles and auto-alert feature.

- Durable Construction - Robust metal frame suitable for continuous testing in lab environments.

- Standard Compliance - Designed to follow standards like GB/T 37635 for elastic fabric testing.

- Prepare the Sample

- Mount the Sample - Secure both ends of the fabric in the upper and lower clamps.

- Set Test Parameters

- Start the Test - Press start on the touch screen interface. - The machine will cyclically stretch and release the sample.

- Monitor Progress - Observe operation or let it run automatically.

- Remove and inspect - Take out the fabric and measure elongation, recovery, or visual defects.

- Record and Compare Results - Compare with initial measurements or standard performance criteria.

Fatigue tester for Elastic fabric

Tensile Strength tester

VeriVide Colour Assessment Cabinets

VeriVide Colour Assessment Cabinets

VeriVide offers high-quality Colour Assessment Cabinets (CACs) such as the CAC 60-4, CAC 60-5, and CAC 120-4&5. These cabinets, originating from the UK, are reliable tools for visual evaluation in quality assurance, meeting national, international, and retailer standards. They effectively mitigate issues related to color assessment.VeriVide Colour Assessment Cabinets

High-quality visual evaluation tool for quality assurance. Adhering to national, international and retailer standards.Colour Assessment Cabinet's (CACs) reduce problems associated with assessing products or samples in different environments,be though geological or seasonal, offering a cost-effective method to ensure visual accuracy and product quality.

Color Light Box Enhance color precision with VeriVide's cutting-edge Colour Assessment

Cabinets. These cabinets are meticulously designed to ensure accurate color evaluation in various industries. Invest in VeriVide Colour Assessment Cabinets to elevate your color assessment process.

Enhance Color Precision with VeriVide's Cutting-Edge Assessment Cabinets, which meet or surpass ISO 3664 and BS 950 Part 1 international standards. The cabinets are adaptable to user requirements, with lamp options to choose different light sources. Available in 60, 120, and 150cm widths, VeriVide Colour Assessment Cabinets provide a flexible solution for accurate color assessment.

Incorporate user-friendly features like servicing indicator, auto sequence, warm-up, power save and data storage.4 or 5 light source options Versions available for colour fastness testing and particulate testing both adhering to global standardsEnsure that you are using the best equipment available as they provide the best fluorescent D65 daylight simulator, with the highest Colour

Rendering Index (CRI), available. VeriVide Colour Assessment Cabinets products are known as light boxes, viewing booths, colour cabinets and others, depending on which industry or country they are serving in. They are used within a wide array of industry sectors throughout the world including textile and apparel, graphics, automotive, ceramics, cosmetics, pharmacology (CAC Particulate),

food, footwear, packaging and printing.Download the Datasheet below for more information or click 'VeriVide CAC Datasheet Here' to get in touch with colour experts.

VeriVide CAC Datasheet Here Features of VeriVide Colour Assessment Cabinets

• CAC 60, CAC 120 and CAC 150 accommodate 60, 120 and 150cm tubes respectively

VeriVide offers high-quality Colour Assessment Cabinets (CACs) such as the CAC 60-4, CAC 60-5, and CAC 120-4&5. These cabinets, originating from the UK, are reliable tools for visual evaluation in quality assurance, meeting national, international, and retailer standards. They effectively mitigate issues related to color assessment.VeriVide Colour Assessment Cabinets

High-quality visual evaluation tool for quality assurance. Adhering to national, international and retailer standards.Colour Assessment Cabinet's (CACs) reduce problems associated with assessing products or samples in different environments,be though geological or seasonal, offering a cost-effective method to ensure visual accuracy and product quality.

Color Light Box Enhance color precision with VeriVide's cutting-edge Colour Assessment

Cabinets. These cabinets are meticulously designed to ensure accurate color evaluation in various industries. Invest in VeriVide Colour Assessment Cabinets to elevate your color assessment process.

Enhance Color Precision with VeriVide's Cutting-Edge Assessment Cabinets, which meet or surpass ISO 3664 and BS 950 Part 1 international standards. The cabinets are adaptable to user requirements, with lamp options to choose different light sources. Available in 60, 120, and 150cm widths, VeriVide Colour Assessment Cabinets provide a flexible solution for accurate color assessment.

Incorporate user-friendly features like servicing indicator, auto sequence, warm-up, power save and data storage.4 or 5 light source options Versions available for colour fastness testing and particulate testing both adhering to global standardsEnsure that you are using the best equipment available as they provide the best fluorescent D65 daylight simulator, with the highest Colour

Rendering Index (CRI), available. VeriVide Colour Assessment Cabinets products are known as light boxes, viewing booths, colour cabinets and others, depending on which industry or country they are serving in. They are used within a wide array of industry sectors throughout the world including textile and apparel, graphics, automotive, ceramics, cosmetics, pharmacology (CAC Particulate),

food, footwear, packaging and printing.Download the Datasheet below for more information or click 'VeriVide CAC Datasheet Here' to get in touch with colour experts.

VeriVide CAC Datasheet Here Features of VeriVide Colour Assessment Cabinets

• CAC 60, CAC 120 and CAC 150 accommodate 60, 120 and 150cm tubes respectively

- Either 4 or 5 light sources available for each model including D65, D50, 840P15, F and UV - see Lamp Options.• Internal finishes in Munsell N5, Munsell N7 or Grey 5574 • Diffuser and/or dimmer options available Dimensions of VeriVide Colour Assessment Cabinets CAC 60-4 Dimensions (mm) Width Height Depth Overall 710 545 420

Random Tumble Pilling Tester

Random Tumble Pilling Tester

The Random Tumble Pilling Tester is a specialized instrument designed to assess the pilling resistance of textile fabrics. Pilling refers to the formation of small, fuzzy balls (pills) on the fabric surface due to wear and friction. This tester simulates the wear conditions that fabrics experience during actual use, providing valuable data on their durability and appearance retention. Purpose of Random Tumble Pilling Tester The primary function of the Random Tumble Pilling Tester is to evaluate how fabrics resist pilling, fuzzing, and matting. This assessment is crucial for manufacturers aiming to ensure the longevity and aesthetic quality of their textile products. Working Principle of Random Tumble Pilling Tester The tester operates by placing fabric specimens into cylindrical test chambers lined with cork. Inside each chamber, a stainless steel impeller rotates at a high speed (typically around 1200 revolutions per minute), causing the fabric samples to tumble randomly. Compressed air is injected to enhance the tumbling action. This process simulates the friction and wear that fabrics undergo during regular use. After a predetermined duration, the samples are removed and visually assessed for pilling using standardized rating scales. Key Specifications of Random Tumble Pilling Tester Test Chambers: Available in configurations of 2 or 4 chambers to accommodate multiple samples simultaneously. - Rotation Speed: Approximately 1200 revolutions per minute. - Chamber Dimensions: Typically around 146 mm in diameter and 152 mm in length. - Impeller Size: Standard impellers measuring about 121 mm. - Compressed Air Pressure: Adjustable, commonly between 14–21 kPa (2–3 psi). - Timer: Digital timer allowing precise control over test duration. - Power Supply: Generally operates on 220V, 50Hz power sources. Applicable Standards of Random Tumble Pilling Tester The Random Tumble Pilling Tester complies with several international testing standards, ensuring its suitability for global applications:- ASTM D3512- ISO 12945-3- DIN 53867- JIS L 1076- GB/T 4802.4 Benefits of Random Tumble Pilling Tester - Realistic Simulation: Accurately replicates the wear and friction conditions fabrics face during actual use.- Standardized Testing: Adheres to international standards, facilitating consistent and comparable results.- Efficient Evaluation: Allows simultaneous testing of multiple samples, increasing laboratory throughput.- Quality Assurance: Provides manufacturers with critical data to improve fabric formulations and production processes. User-Friendly Operation: Features intuitive controls and clear viewing windows for easy monitoring. Applications of Random Tumble Pilling Tester The Random Tumble Pilling Tester is widely used in various sectors of the textile industry: - Apparel Manufacturing: Assessing the durability of clothing fabrics. - Home Textiles: Evaluating materials used in upholstery, curtains, and bedding. - Quality Control Laboratories: Routine testing to ensure product consistency and compliance with standards.- Research and Development: Developing new fabrics with enhanced resistance to pilling. Features of Random Tumble Pilling Tester:- Multiple Test Chambers - Typically comes with 2 or 4 cork-lined chambers for simultaneous testing of multiple fabric samples.

- High-Speed Rotating Impellers - Impellers rotate at around 1200 rpm to create intense, random tumbling motion.

- Compressed Air System - Ensures continuous fabric movement and realistic simulation of wear.

- Digital Timer- Allows precise setting of test duration with easy-to-read display.

- Viewing Windows- Transparent chamber doors for monitoring fabric movement during testing.

- Standard Compliant Design- Meets ASTM D3512, ISO 12945-3, GB/T 4802.4 and other major standards.

- Robust Construction- Durable materials and components designed for long-term laboratory use.

- Easy Sample Handling - Quick-open chamber lids and simple sample placement process.

- Compact Footprint- Saves space in laboratory environments.

- Prepare Samples- Cut fabric into standard-sized specimens (usually circular or rectangular per ASTM/ISO specs)- Condition samples as per the standard (usually 24 hrs at 21°C, 65% RH).

- Load the Chambers - Place each sample into a cork-lined test chamber. - Add a small piece of gray cotton backing fabric if required by the method.

- Set Parameters - Adjust compressed air pressure (typically 14–21 kPa or 2–3 psi).

- Start the Test- Close the chamber doors and press start. - Impellers rotate, tumbling the samples randomly with air flow.

- Stop and Unload - Once the timer ends, remove the samples carefully.

- Evaluate Pilling - Compare the tested samples to standard pilling rating photographs or scales.

- Record Results - Document the pilling grades and any observations.

[Scope of application]:

It is used to test the fuzzing and pilling

performance of the fabric under the condition of

free rolling and friction in the drum.

[Related standards]:

GB/T4802.4 (Standard Drafting Unit)

ISO12945.3, ASTM D3512, ASTM D1375, DIN 53867, ISO 12945-3, JIS L1076, etc.

[Technical parameter]:

1. Number of boxes: 4

2. Roller specifications: diameter (146±1.0) mm, depth (152.4±1.0) mm;

3. Lining material: polychloroprene lining thickness (3.2±0.4) mm. , Hardness (60~70)

IRHD;

4. Impeller specifications: φ12.7 mm×120.6 mm;

5. Plastic blade specifications: 10 mm×65 mm;

6. Rotation speed: 1~2400 rpm can be set freely

7. Working pressure: 14kPa~21kPa;

8. Time counting: (1~999) min.

9. Power supply: AC220V±10% 50Hz 80W

10. Appearance: (480×400×680)mm

11. Weight: 40kg

[Standard accessories]

Items and specifications Qty. Note

Fuse 2 3A

Main machine 1

Power cable 1

Air tube 1 Φ8mm

Grey cotton sliver 4

Cork lining 4

Rating sample photo 1

White glue 1

[Scope of application]:

It is used to test the fuzzing and pilling

performance of the fabric under the condition of

free rolling and friction in the drum.

[Related standards]:

GB/T4802.4 (Standard Drafting Unit)

ISO12945.3, ASTM D3512, ASTM D1375, DIN 53867, ISO 12945-3, JIS L1076, etc.

[Technical parameter]:

1. Number of boxes: 4

2. Roller specifications: diameter (146±1.0) mm, depth (152.4±1.0) mm;

3. Lining material: polychloroprene lining thickness (3.2±0.4) mm. , Hardness (60~70)

IRHD;

4. Impeller specifications: φ12.7 mm×120.6 mm;

5. Plastic blade specifications: 10 mm×65 mm;

6. Rotation speed: 1~2400 rpm can be set freely

7. Working pressure: 14kPa~21kPa;

8. Time counting: (1~999) min.

9. Power supply: AC220V±10% 50Hz 80W

10. Appearance: (480×400×680)mm

11. Weight: 40kg

[Standard accessories]

Items and specifications Qty. Note

Fuse 2 3A

Main machine 1

Power cable 1

Air tube 1 Φ8mm

Grey cotton sliver 4

Cork lining 4

Rating sample photo 1

White glue 1

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Gray scale

Gray Scale

Gray Scale

- Gray Scale for Color Change - Compares the original and tested sample to measure color fading or alteration.

- Gray Scale for Staining - Compares a white adjacent fabric (before and after testing) to assess color transfer or staining.

- Standardized Evaluation - Provides a consistent and objective way to assess color change or staining.

- Simple and Quick to Use - Enables rapid visual comparison during fabric testing.

- Widely Accepted - Complies with international standards (ISO, AATCC) for color fastness grading.

- Cost-Effective Tool - Inexpensive yet essential for reliable quality control in textiles.

- Enhances Quality Assurance - Helps detect dyeing or printing issues before bulk production.

- Supports Multiple Tests - Used for evaluating wash fastness, rubbing fastness, perspiration, light exposure, and more.

- Portable and Durable - Easy to carry and long-lasting with proper care.

- Dual Type Availability - Comes in two types: for Color Change and for Staining.

- 5-Point Grading System - Grades from 1 (poor) to 5 (excellent), with half-step intervals like 4–5, 3–4.

- Standardized Grey Chips - Includes contrasting grey color pairs to match fabric changes accurately.

- Compact Design - Small, portable card or booklet format for easy lab and field use.

- Durable Material - Made from stable, fade-resistant plastic or cardboard for long-term use.

- Compliance with Standards - Follows ISO 105-A02 (Color Change) and ISO 105-A03 (Staining) norms.

- Easy Visual Comparison - Designed for quick side-by-side assessment of fabric before and after testing.

- Place the Samples - Lay the untested (original) and tested fabric side by side (for color change)

- Match Against Gray Scale Chips - Visually compare the difference between the samples and find the closest matching gray pair on the scale.

- Assign a Grade

- Record the Result - Note the grade in your test report as per the test method (e.g., ISO 105).

- Store Properly - Keep the gray scale away from light and moisture to avoid fading.

- Features :

- Dual Type Availability - Comes in two types: for Color Change and for Staining.

- 5-Point Grading System - Grades from 1 (poor) to 5 (excellent), with half-step intervals like 4–5, 3–4.

- Standardized Grey Chips - Includes contrasting grey color pairs to match fabric changes accurately.

- Compact Design - Small, portable card or booklet format for easy lab and field use.

- Gray Scale for Color Change - Used to evaluate the degree of color fading or change in a fabric after testing (e.g., washing, light exposure). - Assesses how much the original color has altered.

- Gray Scale for Staining - Used to assess the degree of color transfer from a dyed fabric to an adjacent white fabric during testing (e.g., rubbing, washing).

Gray Scale

Stretch Recovery Tester Static Method

Stretch Recovery Tester Static Method

Stretch Recovery Tester

- A sample is stretched to a predetermined extension or force.

- The stretch is maintained for a set period.

- After removing the load, the recovery (return to original length) is measured after a fixed time.

- The fabric sample is clamped and stretched to a specific length or force.

- It’s held for a fixed duration (e.g., 1–5 minutes).

- The tension is released, and the sample is allowed to recover.

- The recovered length is measured after a set time.

Stretch Recovery Tester

Bursting strength tester

Bursting strength tester

true burst

- Available with automatic test strip feeder Measurements are simple to make with the Mullen type Bursting Strength Tester. Fast automatic measurements Measurement starts automatically once a test piece has been placed in the measuring gap. The clamping foot descends, and a bursting strength measurement is made.

- Bursting pressure can reach up to 1.2MPa 5. The maximum burst and expansion degree can reach 70mm. 6. Strengthen the lighting system on the test surface. 7. The main aerodynamic force helps to clamp the sample system. 8. A variety of test areas are available, and the switching is easy.

- A variety of unit conversions between Chinese and English. 10. Reliable anti-pinch safety protection design. [Technical parameter]: 1. Test range: (0~1)Mpa (the range above 1Mpa needs to be customized) 2. The minimum graduation value: 0.0001Mpa 3. Pressurization mode: direct pressurization, timing pressurization, and expansion degree pressurization.

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated