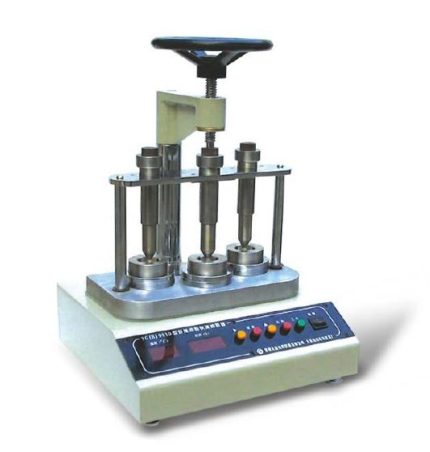

Fastness Rotary Friction Tester

$0.00

Fastness Rotary Friction Tester

A Fastness Rotary Friction Tester, also known as a Rotary Crock meter, is a specialized instrument used to evaluate the color fastness of textiles and materials when subjected to rotational rubbing. This test simulates the wear and friction that fabrics experience during use, helping manufacturers assess the durability of dyes and finishes.

Purpose of Fastness Rotary Friction Tester

The primary function of the Fastness Rotary Friction Tester is to determine how well a fabric’s color withstands rubbing, both in dry and wet conditions. This is crucial for ensuring the longevity and appearance of textiles in real-world applications, such as clothing, upholstery, and footwear.

Working Principle of Fastness Rotary Friction Tester

The tester operates by applying a specified pressure to a fabric sample using a standardized rubbing finger covered with a test cloth. The rubbing finger performs a set number of rotational movements (typically 1.125 turns clockwise followed by 1.125 turns counterclockwise) over the fabric surface. After the test, the degree of color transfer to the test cloth and any changes in the fabric’s appearance are evaluated against standardized gray scales.

Common Testing Standards

– AATCC 116: Colorfastness to Crocking: Rotary Vertical Crock meter Method.

ISO 105 X16: Textiles—Tests for color fastness—Part X16: Color fastness to rubbing—small areas.

– SATRA TM8: Color fastness to rubbing.

Key Specifications of Fastness Rotary Friction Tester

– Rubbing Head Diameter: Typically 16 mm.

– Applied Pressure: Approximately 1134 grams (11.1 N).

– Rotation: 1.125 turns clockwise followed by 1.125 turns counterclockwise.

– Sample Size: Commonly 60 mm × 60 mm.

– Test Cloth: Standardized white cotton cloth, either dry or wetted depending on the test condition.

Benefits of Fastness Rotary Friction Tester

– Realistic Simulation: Mimics the actual wear and friction fabrics undergo during use.

– Versatility: Applicable to a wide range of materials, including textiles, leather, and printed fabrics.

– Quality Assurance: Ensures products meet industry standards for color durability.

– Standard Compliance: Aligns with international testing standards, facilitating global trade and quality benchmarks.

Applications Fastness Rotary Friction Tester

– Textile Industry: Assessing the color durability of garments, upholstery, and other fabric products.

– Footwear Manufacturing: Testing the colorfastness of shoe uppers and linings.

– Automotive Interiors: Evaluating the wear resistance of seat covers and other interior fabrics.

Quality Control Laboratories: Routine testing to ensure product consistency and compliance with standards.

Benefits of Fastness Rotary Friction Tester:

- Accurate Colorfastness Evaluation- Provides precise assessment of how well fabric resists color loss and staining from rubbing.

- Simulates Real-World Wear – Recreates rotational friction found in actual use (e.g., seat covers, apparel wear points).

- Supports Wet & Dry Testing – Can test under both dry and wet conditions for comprehensive results.

- Standardized Testing – Complies with global standards (AATCC 116, ISO 105 X16), ensuring reliable and comparable results.

- Time-Saving & Efficient – Quick to set up and run, allowing for high-throughput testing in labs.

- Versatile Use- Suitable for textiles, leather, coated fabrics, and printed surfaces.

- Improves Quality Control – Identifies potential durability issues early in the production process.

- Enhances Product Performance – Helps in developing fabrics with better resistance to rubbing and abrasion.

Features of Fastness Rotary Friction Tester:

- Rotary Rubbing Mechanism – Simulates 1.125 clockwise and 1.125 counterclockwise turns for realistic friction.

- Standardized Rubbing Head – Fixed diameter (typically 16 mm) with specified pressure (≈1134 g) for consistent results.

- Dry and Wet Testing Capability – Can perform tests using dry or wet rubbing cloths.

- Sample Holder- Secure and easy-to-use fixture for holding fabric samples in place.

- Test Cloth Mounting Arm- Quick attachment for standardized white rubbing cloths.

- Simple Operation – Manual or motorized operation depending on model; easy to handle for lab technicians.

- Compliance with Standards – Follows AATCC 116, ISO 105 X16, and SATRA TM8 protocols.

How to Use Fastness Rotary Friction Tester:

- Prepare the Sample – Cut a fabric piece (typically 60 × 60 mm) and condition it per standard requirements.

- Mount the Fabric – Secure the fabric sample on the sample holder or base plate of the tester.

- Attach Rubbing Cloth – Place a standard white test cloth (dry or wetted as required) over the rubbing head.

- Apply Pressure – Lower the rubbing head onto the fabric. Standard weight is about 1134 g.

- Start the Test – Operate the tester: the head performs 1.125 turns clockwise, then 1.125 turns counterclockwise.- Number of cycles (typically 10 or 20) is set based on the test standard.

- Remove and Inspect – After testing, remove the rubbing cloth and assess any color transfer using a gray scale.

- Evaluate Fabric Surface – Check the fabric for visible changes, fading, or wear.

- Record Results – Grade both staining and fabric change per standard gray scale ratings.

Fastness rotary friction tester

[Scope of application]

It is used to change the color fastness of the textile,

It is used to change the color fastness of the textile,

printing and dyeing, printing and other products after a specific track friction.

[Related standards]

GB / T29865 AATCC116 ISO105-X16, etc.

[Instrument characteristics]:

1.Single-chip control, speed can be set freely

2.Imported motor, linear guide, low noise, suitable for long time work

3. Liquid crystal display, film panel

4. Freely set the number of friction, can count up and down,

and automatically stop the alarm when the set value is reached

[Technical Parameters]:

1. Friction head diameter: 16mm 25mm

2. Vertical pressure: 11.1N

3. Working mode: 405 ° clockwise and 405 ° counterclockwise

4. Speed range: constant 60 rpm, LCD display, thin mold panel

5. Counting range: 0-99999 times

6. Power supply: AC 220V 50Hz 80W

7. Weight: 20KG

8. Volume: L420mm × W260mm × H430mm

Related products

Laboratory mini stenter Dryer

Laboratory mini stenter Dryer

A Laboratory Mini Stenter Dryer is a compact, lab-scale machine designed to simulate the drying and heat-setting processes used in textile finishing. It mimics the function of industrial stenter machines but on a much smaller scale, making it ideal for testing fabric behavior, shrinkage, and finish quality under controlled conditions. Key Features:- Controlled Heating System

- Adjustable Fabric Width

- Variable Speed Conveyor - Allows control over fabric dwell time for drying or heat-setting.

- Compact and Bench-Top Design - Space-saving design ideal for textile labs and R&D units.

- Digital Controls - Easy-to-use digital interface for setting temperature, conveyor speed, and process time.

- Transparent Viewing Window - Allows operators to monitor fabric movement and drying visually.

- Low Energy Consumption - Designed for lab use, consuming less power than industrial models.

- Accurate Simulation of Production - Mimics industrial stenter conditions on a lab scale, ideal for pre-production testing and R&D.

- Cost-Effective Testing - Enables testing and fabric finishing without the high cost or space requirements of full-scale machines.

- Energy Efficient - Consumes less power compared to large stenters, making it economical for small-scale or frequent use.

- Precise Control - Offers accurate control of temperature, speed, and fabric tension, ensuring consistent results.

- Space-Saving Design - Compact and bench-top friendly, perfect for laboratories with limited space.

- Multiple Applications - Useful for drying, heat-setting, shrinkage testing, and evaluating chemical finishes.

- Faster Development Cycles - Speeds up new product development by allowing rapid sample testing and adjustments.

- Improved Fabric Quality - Helps optimize finishing parameters for better dimensional stability, hand feel, and appearance.

- Safe and User-Friendly- Designed with lab safety in mind, including temperature safety controls and easy operation.

- Compact Bench-Top Design - Ideal for laboratory use with limited space requirements.

- Adjustable Temperature Control - Precise heating (usually up to 220–250°C) with digital controllers for accurate processing.

- Variable Conveyor Speed- Allows adjustment of fabric dwell time for different drying or heat-setting needs.

- Width Adjustment Mechanism - Equipped with clips or pins to stretch and fix fabric width-wise, simulating industrial stenter conditions.

- Transparent Viewing Window - Enables visual monitoring of fabric movement and drying inside the chamber.

- Digital Display Panel- Easy-to-use interface for setting and monitoring temperature, speed, and time.

- Stainless Steel Construction- Durable and corrosion-resistant for long-term use at high temperatures.

- Uniform Heat Distribution- Ensures consistent fabric treatment across the width.

- Safety Features- Over-temperature protection and insulated body for operator safety.

- Versatile Applications - Suitable for drying, heat-setting, shrinkage testing, and chemical finish evaluations.

Martindale abrasion tester Updated

Martindale abrasion tester updated

Latest Update 1 A+

- Clothing sample weight hammer:397±2g Furniture decoration sample weight hammer:597±2g C. Stainless steel discs:260±1g

- Effective friction diameter of grinding block: Type A 198g(3kpa) friction head 28.8-0.084mm Type B 155g(1.52N) friction head 90-0.10mm 6. Relative velocity of gripper and grinding table:50 + 2R / MI (20-70r / min adjustable) 7. Sampling hammer quality:2385±10g 8. Shape size:870×580×300mm 9. power supply:AC220V 50Hz 500W 10.Weight:73KG.

- [Standard accessories] Items and specifications Qty Notes Main machine 1Power cable 1A type 198g Friction head 9 B type 155g(1.52N) Friction head 9 597g Hammer 9 397g Hammer 9, 666666666 260g Stainless steel disc 9, 2385g Holding hammer 1,B Friction head felt 18 ¢90mm Steel ball 6, Rubber ring 18, Inner Hexagonal Wrench 1

- Sampler 1, Fuse 2 3A, Standard felt 18, Weight:750±50g/m2, Thickness:2.5±0.5mm, Standard foam lining 40, Density:0.03g/cm3,Thickness:3mm,Standard abrasive 9 Circular shear template Each φ140mm、φ38mm,Small screw knife 1, Bottom foot 4

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Fabric air permeability tester

Fabric Air Permeability Tester

Fabric Air Permeability Tester is a lab instrument used to measure how easily air passes through a fabric. It quantifies the air permeability, which is crucial for evaluating breathability, comfort, and functional performance in textiles. Purpose Fabric Air Permeability Tester: It determines the rate of airflow through a fabric sample under a set air pressure, typically reported in units like cm³/cm²/s or L/m²/s. Working Principle: The tester creates a pressure difference across the fabric sample and measures the volume of air flowing through it. Higher air permeability means the fabric is more breathable. Main Components of Fabric Air Permeability Tester: - Test Head / Clamp: Holds the fabric securely without leakage. - Pressure Regulator: Maintains a constant air pressure during testing. - Flow Meter or Digital Sensor: Measures the actual airflow rate through the fabric. - Display Unit: Shows readings of air permeability instantly. Applications of Fabric Air Permeability Tester: - Performance textiles (sportswear, PPE) - Technical fabrics (filters, tents, airbags) - Medical textiles (masks, gowns) - Nonwovens and industrial materials Benefits of Fabric Air Permeability Tester:- Accurate Breathability Measurement - Precisely measures how breathable a fabric is, essential for comfort and performance.

- Supports Quality Control - Ensures consistent air permeability in fabric batches, critical for products like PPE, sportswear, and filters.

- Enhances Product Design - Helps in selecting or engineering fabrics with the right airflow properties for specific uses.

- Standard Compliance - Conforms to international testing standards (e.g., ASTM D737, ISO 9237), ensuring global credibility.

- Quick and Reliable Testing - Provides rapid results, increasing lab efficiency and production decision-making speed.

- Wide Material Compatibility - Suitable for woven, nonwoven, knitted fabrics, and even paper or coated materials.

- Improves Functional Performance - Helps optimize products for ventilation, moisture control, and thermal comfort.

- Reduces Product Failure - Identifies underperforming fabrics early, minimizing risks in high-performance applications.

- Digital Display - Shows air permeability readings clearly in units like L/m²/s or cm³/cm²/s.

- Precise Test Head/Clamp - Provides an airtight seal to prevent air leakage and ensure accurate results.

- Adjustable Pressure Settings - Allows testing under various pressure drops (e.g., 10–2500 Pa), depending on fabric type.

- Automatic Airflow Measurement - Built-in sensors or flow meters capture airflow rate automatically for quick analysis.

- Multiple Test Area Sizes - Interchangeable test plates to match different sample sizes and standard requirements.

- Data Logging and Export - Some models include USB or software connectivity for storing and exporting test results.

- Standard Compliance - Conforms to ASTM D737, ISO 9237, BS 5636, DIN 53887, etc.

- Robust Construction - Built with corrosion-resistant materials and durable components for long-term lab use.

- Low Maintenance - Simple cleaning and calibration process for reliable performance.

- Compact and User-Friendly Design - Ideal for lab benches and easy operation with minimal training.

- Prepare the Sample - Cut the fabric sample to the required size (usually circular, e.g., 20 cm²).

- Mount the Sample - Place the fabric securely in the test clamp or holder, ensuring no wrinkles or gaps.

- Set Test Parameters - Adjust the air pressure drop according to the fabric type or standard (e.g., 100 Pa).

- Start the Test - Turn on the air supply and start the airflow through the fabric.

- Read the Measurement - The digital display will show the air permeability value in the selected units.

- Record the Results - Note the readings or export data if the device supports it.

- Repeat if needed - Test multiple samples or areas for accuracy and average the results.

- Clean and Maintain - After testing, clean the clamp and ensure the device is calibrated regularly.

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm

r Permeability Tester

Appliance Range

It is used to TEST the air permeability of various textile fabrics, including industrial fabrics, nonwoven fabrics and other textile products and other breathable materials.

Related Standards

GB / T 5453, GB / T 13764, ISO 9237, ISO 5636, ASTM D737, etc.

Instrument characteristics

1. Automatic sample clamping, automatic nozzle replacement, and quick test.

2. Microcomputer processing, the test results are displayed directly, without manual table calculation;

3. Built-in continuous test mode, the test unit can be switched as needed.

4. Chinese LCD menu operation, configure computer interface.

Technical parameter

1. Range of sample pressure difference: 1 ~ 4000Pa

2. Measurable air permeability: 1 ~ 40,000mm / s

3. Measurement error: ≤ ± 2%

4. Measurable fabric thickness: ≤8mm

5. Test area: 5cm2; 20cm2; 50cm2; 100cm2

Ф50mm (≈19.6cm2)

Ф70mm (≈38.5cm2)

6. Nozzles: 11 in total (automatic replacement of digital setting)

CODE 00 01 02 03 04 05 06 07 08 09 10

DIAφ(mm)

0.8 1.2 2 3 4 6 8 10 12 16 20

7.Data Capacity:≤200 times tests

8.Power Supply:AC220V 50Hz 2KW

9.Weight:80Kg

10.Shape:1250×700×1250mm Hydraulic GSM Cutter

Hydraulic GSM Cutter

Hydraulic GSM Cutter

- High Cutting Precision - Ensures consistent and accurate fabric sample size for reliable GSM results.

- Effortless Operation- Hydraulic action reduces manual effort and operator fatigue.

- Ideal for Thick or Multi-Layer Fabrics - Cuts through dense or multiple fabric layers cleanly.

- Time-Saving - Speeds up the sample preparation process, especially for high-volume testing.

- Improves Test Accuracy - Uniform samples help eliminate errors in GSM calculation.

- Durable and Long-Lasting - Robust construction ensures stability and extended service life.

- Safety Enhancement - Reduces risk of injury compared to manual rotary cutters.

- Consistent Pressure Application - Hydraulic mechanism maintains steady force for each cut.

- Hydraulic Press Mechanism - Applies consistent and strong pressure for clean, even cuts.

- Standard Cutting Die (100 cm²) - Produces fabric samples suitable for GSM testing with standard area.

- Heavy-Duty Construction - Built with robust metal frame for long-term lab or industrial use.

- Sharp Stainless Steel Blades - Durable and replaceable blades ensure smooth, precise cuts.

- Cutting Pad Included - Comes with a rubber or nylon base to protect blades and ensure clean edges.

- Simple Lever or Button Operation - Easy to use with minimal training required.

- Non-slip Base - Provides stability during operation for safe, accurate cutting.

- Supports Various Fabric Types

- Place the Cutting Pad - Lay the rubber or nylon cutting pad on a flat surface.

- Position the Fabric - Place the fabric sample flat and smooth on the cutting pad.

- Align the Cutter - Position the GSM cutter die over the desired area of the fabric.

- Activate Hydraulic Press - Pull the lever or press the button to apply hydraulic pressure and cut the sample.

- Remove the Sample - Lift the cutter and carefully take out the circular fabric piece (usually 100 cm²).

- Weigh the Sample - Place the cut sample on a precision balance or GSM scale to determine weight.

- Calculate GSM - Multiply the sample weight (in grams) by 100 to get GSM.

Hydraulic GSM Cutter

Digital Elmendorf tearing tester

Digital Elmendorf Tearing Tester

Digital Elmendorf Tearing Tester is a precision instrument used to measure the tear strength of materials like woven fabrics, paper, plastic films, and nonwovens. It determines how much force is required to continue tearing a pre-slit sample. Key Functions of Digital Elmendorf Tearing Tester: - Measures propagation tear resistance, not initial tear. - Uses a pendulum to apply force; the energy lost during tearing is calculated to determine tear strength. - Equipped with a digital display for direct reading of results in grams or millinewtons. Core Components: - Pendulum Arm: Applies tearing force. - Clamps: Secure the sample before and after the tear. - Cutting Blade: Creates a precise slit at the start of the test. - Digital Display Unit: Shows the tearing force result clearly and instantly. - Counterweights: Optional weights for increasing test range (for stronger materials). Applications of Digital Elmendorf Tearing Tester: - Testing tear resistance of: - Textile fabrics (especially woven) - Paper and cardboard - Plastic films - Nonwovens - Packaging materials Benefits of Digital Elmendorf Tearing Tester:- Accurate Tear Strength Measurement - Provides precise data on tear resistance, critical for quality control and product performance.

- Digital Readout - Easy-to-read display gives instant, reliable results without manual calculations.

- High Reproducibility - Ensures consistent test outcomes due to controlled tearing angle and speed.

- Fast Testing Process - Simple loading and quick test cycle increase lab efficiency.

- Suitable for Various Materials - Tests a wide range of flexible materials like textiles, paper, plastic, and packaging.

- Customizable Range - Use of optional weights extends the test range for low to high tear strength materials.

- Low Sample Waste - Requires small fabric or material samples, reducing waste during testing.

- Standards Compliance - Meets international testing standards (e.g., ASTM D1424, ISO 13937) for credibility and uniformity.

- Precision Sample Clamp - Securely holds samples in place to ensure accurate tear initiation.

- Pre-Cutting Blade - Integrated knife creates a precise initial slit in the sample before tearing.

- User-Friendly Interface - Simple buttons and screen navigation for ease of operation.

- Standard Test Compliance - Compatible with ASTM D1424, ISO 1974, ISO 13937, and other tear strength standards.

- Sturdy Construction - Made with durable materials for long-lasting performance and stable operation.

- Compact Design - Space-efficient footprint ideal for laboratory environments.

- Data Output Options- Some models offer USB or printer connectivity for result documentation.

- Prepare the Sample - Cut the material (fabric, paper, film, etc.) to standard size (typically 100 × 63 mm for textiles) and slit it with the pre-cutter as required.

- Select Pendulum Weight - Choose the appropriate pendulum or add counterweights based on expected tear strength.

- Calibrate the Machine - Set the pendulum to its starting position and zero the display.

- Clamp the Sample - Fix one half of the sample in the stationary clamp and the other in the moving clamp.

- Cut the Initial Slit - Use the integrated blade to make a precise cut at the marked slit area (usually 20 mm).

- Release the Pendulum - Trigger the pendulum to swing and tear the sample through the pre-slit.

- Read the Result - The digital display will show the tearing force automatically (in g, mN, or cN).

- Record or Export Data - Save or print the result if your model supports USB or printer connection.

- Reset for Next Test - Reposition the pendulum and prepare a new sample for the next cycle.

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.)

Scope of application

It is used for the determination of the tear resistance of various woven

fabrics (Elmendorf method), and it can also be used for the determination

of the tear resistance of thick paper, plastic sheeting, electrical tape, etc.

Related standards

GB/T 3917.1 FZ/T60006 FZ/T75001 ISO1974/9290 ASTM D1424/5734

etc.

Instrument characteristics

1. Maximum 300N test range

2. Microcomputer control, digital decoding, support online

communication

3. Color touch screen control, Chinese and English menu operation

interface

4. Pneumatic clamping, automatic cutting

5. A variety of measurement units (cN, gf) selection

6. Fully automatic operation with safe operation protection.

7. Automatically increase potential energy

[Technical parameter]:

1. Test range: first gear: (0~16)N second gear: (0~32)N third gear: (0~

64)N fourth gear: (0~128)N fifth gear: (0~300)N

2. Test accuracy: ≤±0.2%F·S

3. Tearing length: 43mm (non-standard 30-60mm can be set)

4. Automatic incision length: (20±0.2)mm

5. Sample size: (100×63)mm

6. Specimen clamping: pneumatic way

7. Sample test: Up to 10 sets per group on the device side, and 30 sets

of data can be selected to be saved

8. Power supply: AC220V±10% 50Hz 100W

9. Dimensions: (650×660×680)mm

10. Weight: 50kg

[Sample of control interface]:(English version is also available.) Digital Temperature Humidity Meter

Digital Temperature Humidity Meter

Digital Temperature Humidity Meter

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

Color Matching Cabinet-Light Box

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated