Fabric drape tester

$0.00

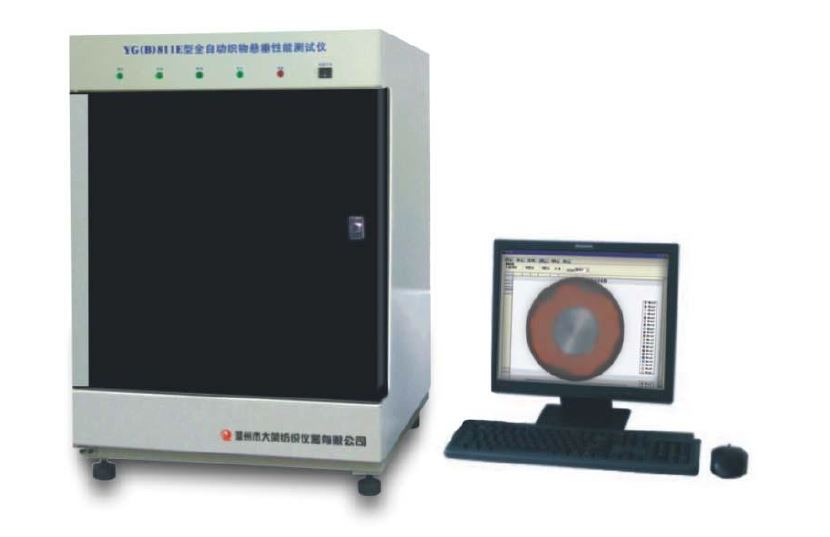

Fabric Drape Tester

Fabric Drape Tester is a lab device used to measure the drape ability of fabric—how it hangs under its own weight. It assesses how fabric conforms in folds or waves, which affects garment appearance and comfort.

Purpose of Fabric Drape Tester:

To evaluate the aesthetic and functional behavior of a fabric when suspended, especially important in apparel and home textiles.

Working Principle:

A circular fabric specimen is placed over a smaller disc. The unsupported edges drape downward. A light source casts a shadow of the draped shape onto a recording surface or scanner. The area of the shadow is measured to calculate the drape coefficient.

Main Components of Fabric Drape Tester:

– Rotating Support Disc: Holds the fabric.

– Light Source: Projects the drape shadow.

– Paper or Digital Scanner: Captures the drape outline.

– Template: For cutting fabric to standard test size.

– Software or Plan meter: Calculates the drape coefficient.

Applications of Fabric Drape Tester:

– Fashion and apparel design

– Fabric development

– Quality control in woven, knitted, or nonwoven fabrics

Benefits of Fabric Drape Tester:

- Quantifies Fabric Flow – Measures drape behavior accurately, crucial for garments and furnishings.

- Supports Design Decisions – Helps designers select fabrics that match the intended look and movement of a product.

- Improves Garment Fit and Comfort – Ensures fabrics behave naturally on the body, enhancing wear ability.

- Enhances Product Aesthetics – Prevents stiff or limp fabric choices in fashion, interior, or technical textiles.

- Standardized Evaluation – Enables comparison across fabrics using drape coefficient, based on standards (e.g., BS 5058).

- Supports R&D – Useful in developing new fabrics or finishes to improve drape quality.

- Non-Destructive Testing – Tests fabric without damaging it, allowing for further analysis.

- Boosts Quality Control – Identifies batch inconsistencies or performance issues early in production.

Features of Fabric Drape Tester:

- Rotating Support Disc – Holds the fabric sample over a smaller disc to create natural drape.

- Standard Sample Size Support – Designed for circular fabric samples, usually 30 cm in diameter.

- Light Projection System – Projects the draped fabric’s shadow onto a screen or recording surface.

- Drape Coefficient Calculation – Measures the shadow area to compute the drape coefficient (percentage of unsupported area covered by the shadow).

- Digital or Manual Options – Available in models with digital image processing or manual plan meter tracing.

- Stable Base and Structure – Ensures consistent and vibration-free testing conditions.

- Sample Templates Provided – For cutting precise, standard-sized fabric specimens.

- User-Friendly Interface – Simple controls for rotation and light alignment.

- Compact and Lab-Ready Design – Fits easily on lab benches and in testing environments.

- Compliance with Testing Standards – Supports BS 5058 and other relevant drape measurement methods.

How to Use Fabric Drape Tester:

- Prepare the Fabric Sample – Cut a circular fabric sample, typically 30 cm in diameter, using the provided template.

- Place the Fabric – Center the fabric sample over the smaller support disc (usually 18 cm diameter) on the tester.

- Turn on the Light Source – Illuminate the fabric from above so it casts a shadow onto the recording surface or paper below.

- Capture the Shadow Outline – Trace the shadow manually on paper or capture it digitally, depending on the model.

- Measure the Shadow Area – Use a plan meter (manual) or software (digital) to determine the shadow’s area.

- Calculate Drape Coefficient (DC) – Use the formula:

DC (%) = (Shadow Area – Support Disc Area) / (Full Fabric Area – Support Disc Area) × 100

- Record the Result – Log the drape coefficient to evaluate how stiff or flexible the fabric is.

- Repeat for Accuracy – Test multiple samples and average the results for consistency.

fabric drape tester

Scope of application

It is used for testing dynamic and static drape properties

(drape coefficient, shape change rate, surface ripple and drape uniformity, etc.)

of various fabrics.

Related standards GB/T23329 FZ/01045 BS5058 etc.

Instrument characteristics

1. CCD imaging, dynamic and static image processing.

2. A variety of charts and data statistics, analysis, storage, output

3. No need to replace background color, can test all kinds of color samples.

4. Work mode:Microcomputer control, CCD imaging, automatic processing of images and data automatically.

Technical parameters

1. Communication interface: RS232, USB

2. Image sensor: CCD sensor.

3. Static (dynamic) state draping coefficient: 0 ~ 100% + 2

4. Drapability uniformity: 0 ~ 100% + 2

5. The rate of morphological change is 0 to 100% + 2.

6. Surface waviness error: + 1

Related products

Laboratory mini stenter Dryer

Laboratory mini stenter Dryer

A Laboratory Mini Stenter Dryer is a compact, lab-scale machine designed to simulate the drying and heat-setting processes used in textile finishing. It mimics the function of industrial stenter machines but on a much smaller scale, making it ideal for testing fabric behavior, shrinkage, and finish quality under controlled conditions. Key Features:- Controlled Heating System

- Adjustable Fabric Width

- Variable Speed Conveyor - Allows control over fabric dwell time for drying or heat-setting.

- Compact and Bench-Top Design - Space-saving design ideal for textile labs and R&D units.

- Digital Controls - Easy-to-use digital interface for setting temperature, conveyor speed, and process time.

- Transparent Viewing Window - Allows operators to monitor fabric movement and drying visually.

- Low Energy Consumption - Designed for lab use, consuming less power than industrial models.

- Accurate Simulation of Production - Mimics industrial stenter conditions on a lab scale, ideal for pre-production testing and R&D.

- Cost-Effective Testing - Enables testing and fabric finishing without the high cost or space requirements of full-scale machines.

- Energy Efficient - Consumes less power compared to large stenters, making it economical for small-scale or frequent use.

- Precise Control - Offers accurate control of temperature, speed, and fabric tension, ensuring consistent results.

- Space-Saving Design - Compact and bench-top friendly, perfect for laboratories with limited space.

- Multiple Applications - Useful for drying, heat-setting, shrinkage testing, and evaluating chemical finishes.

- Faster Development Cycles - Speeds up new product development by allowing rapid sample testing and adjustments.

- Improved Fabric Quality - Helps optimize finishing parameters for better dimensional stability, hand feel, and appearance.

- Safe and User-Friendly- Designed with lab safety in mind, including temperature safety controls and easy operation.

- Compact Bench-Top Design - Ideal for laboratory use with limited space requirements.

- Adjustable Temperature Control - Precise heating (usually up to 220–250°C) with digital controllers for accurate processing.

- Variable Conveyor Speed- Allows adjustment of fabric dwell time for different drying or heat-setting needs.

- Width Adjustment Mechanism - Equipped with clips or pins to stretch and fix fabric width-wise, simulating industrial stenter conditions.

- Transparent Viewing Window - Enables visual monitoring of fabric movement and drying inside the chamber.

- Digital Display Panel- Easy-to-use interface for setting and monitoring temperature, speed, and time.

- Stainless Steel Construction- Durable and corrosion-resistant for long-term use at high temperatures.

- Uniform Heat Distribution- Ensures consistent fabric treatment across the width.

- Safety Features- Over-temperature protection and insulated body for operator safety.

- Versatile Applications - Suitable for drying, heat-setting, shrinkage testing, and chemical finish evaluations.

ICI Pilling & Snagging Test Machine

Fabric flame retardant tester

Fabric Flame Retardant Tester

A Fabric Flame Retardant Tester is a specialized laboratory instrument designed to evaluate the flammability characteristics of textiles. It assesses how fabrics react to direct flame exposure, measuring parameters such as ignition time, flame spread rate, after-flame duration, and afterglow time. This testing is crucial for ensuring that textiles meet safety standards for various applications, including apparel, home furnishings, and industrial uses. Purpose and Applications The primary purpose of a Fabric Flame Retardant Tester is to determine the flame resistance of textile materials. This is essential for:- Apparel Safety: Ensuring garments, especially children's sleepwear and industrial work wear, meet flammability standards. - Home Textiles: Testing curtains, drapes, upholstery, and bedding for fire safety compliance. - Technical Textiles: Evaluating materials used in tents, protective clothing, and automotive interiors. ⚙️ Key Features Modern Fabric Flame Retardant Testers incorporate several features to ensure accurate and reliable testing:- Adjustable Burner Angles: Allowing tests at various orientations (e.g., 0°, 45°, 90°) to simulate different real-world scenarios. Automated Ignition Systems: Providing consistent flame application and reducing operator variability. - Digital Timing Mechanisms: Accurately recording ignition time, flame spread, after-flame, and afterglow durations. - Transparent Observation Windows: Enabling safe monitoring of the test without exposure to hazards. - Compliance with International Standards: Meeting protocols such as ASTM D6413, ISO 6941, and EN ISO 15025 for standardized testing procedures. Testing Standards Fabric Flame Retardant Testers are designed to comply with various international standards, including: - ASTM D6413: Standard Test Method for Flame Resistance of Textiles (Vertical Test). - ISO 6941: Textiles — burning behavior — Measurement of flame spread properties of vertically oriented specimens. - EN ISO 15025: Protective clothing — Protection against heat and flame — Method of test for limited flame spread. ️ How It Works- Sample Preparation: A fabric specimen is cut to specified dimensions and conditioned as per standard requirements.

- Mounting: The sample is mounted vertically or at a specified angle in the testing chamber.

- Ignition: A controlled flame is applied to the fabric for a predetermined time.

- Observation: The tester records ignition time, flame spread, after-flame time, and afterglow time.

- Evaluation: Results are compared against standard criteria to determine compliance.

- Prepare the Sample

- Mount the Sample

- Set Up the Burner Position the burner at the required angle (usually 90° for vertical tests).

- Ignite the Flame - Apply the flame to the bottom edge of the fabric for 12 seconds.

- Observe and Measure - Start timing when flame is applied.

- Record the Results

- Compare with Standards

burning of flammable textile materials after ignition.

(specific ignition nozzles and sample holders can be customized to meet multiple criteria).

Related standards

GB/T14644 ASTM D1230 CFR1610 etc.

Technical parameters

1. The spread of time:0 ~ 999.9S resolution 0.1S

2. The temperature inside the box shows:Room temperature -99 degrees C resolution 1 c

3. Igniting time:1S

4. Type of igniter:4 1/2 syringe

5. Sample clip size:Outer frame:204mm * 78mm inner frame:152mm×38mm

6. Distance from the top of the igniter to the sample surface:8mm

7. Studio size and outline size

Studio size:370mm×220mm×350mm

Outline size:375mm×245mm×478mm

8. Power supply:AC220V 50Hz 20W

9. Weight:18Kg

burning of flammable textile materials after ignition.

(specific ignition nozzles and sample holders can be customized to meet multiple criteria).

Related standards

GB/T14644 ASTM D1230 CFR1610 etc.

Technical parameters

1. The spread of time:0 ~ 999.9S resolution 0.1S

2. The temperature inside the box shows:Room temperature -99 degrees C resolution 1 c

3. Igniting time:1S

4. Type of igniter:4 1/2 syringe

5. Sample clip size:Outer frame:204mm * 78mm inner frame:152mm×38mm

6. Distance from the top of the igniter to the sample surface:8mm

7. Studio size and outline size

Studio size:370mm×220mm×350mm

Outline size:375mm×245mm×478mm

8. Power supply:AC220V 50Hz 20W

9. Weight:18Kg

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Counting Balance-Weighing Scale

Martindale abrasion tester Updated

Martindale abrasion tester updated

Latest Update 1 A+

- Clothing sample weight hammer:397±2g Furniture decoration sample weight hammer:597±2g C. Stainless steel discs:260±1g

- Effective friction diameter of grinding block: Type A 198g(3kpa) friction head 28.8-0.084mm Type B 155g(1.52N) friction head 90-0.10mm 6. Relative velocity of gripper and grinding table:50 + 2R / MI (20-70r / min adjustable) 7. Sampling hammer quality:2385±10g 8. Shape size:870×580×300mm 9. power supply:AC220V 50Hz 500W 10.Weight:73KG.

- [Standard accessories] Items and specifications Qty Notes Main machine 1Power cable 1A type 198g Friction head 9 B type 155g(1.52N) Friction head 9 597g Hammer 9 397g Hammer 9, 666666666 260g Stainless steel disc 9, 2385g Holding hammer 1,B Friction head felt 18 ¢90mm Steel ball 6, Rubber ring 18, Inner Hexagonal Wrench 1

- Sampler 1, Fuse 2 3A, Standard felt 18, Weight:750±50g/m2, Thickness:2.5±0.5mm, Standard foam lining 40, Density:0.03g/cm3,Thickness:3mm,Standard abrasive 9 Circular shear template Each φ140mm、φ38mm,Small screw knife 1, Bottom foot 4

Digital Temperature Humidity Meter

Digital Temperature Humidity Meter

Digital Temperature Humidity Meter

GSM Cutter with Balance

GSM Cutter with Balance

GSM Cutter with Balance

VeriVide Colour Assessment Cabinets

VeriVide Colour Assessment Cabinets

VeriVide offers high-quality Colour Assessment Cabinets (CACs) such as the CAC 60-4, CAC 60-5, and CAC 120-4&5. These cabinets, originating from the UK, are reliable tools for visual evaluation in quality assurance, meeting national, international, and retailer standards. They effectively mitigate issues related to color assessment.VeriVide Colour Assessment Cabinets

High-quality visual evaluation tool for quality assurance. Adhering to national, international and retailer standards.Colour Assessment Cabinet's (CACs) reduce problems associated with assessing products or samples in different environments,be though geological or seasonal, offering a cost-effective method to ensure visual accuracy and product quality.

Color Light Box Enhance color precision with VeriVide's cutting-edge Colour Assessment

Cabinets. These cabinets are meticulously designed to ensure accurate color evaluation in various industries. Invest in VeriVide Colour Assessment Cabinets to elevate your color assessment process.

Enhance Color Precision with VeriVide's Cutting-Edge Assessment Cabinets, which meet or surpass ISO 3664 and BS 950 Part 1 international standards. The cabinets are adaptable to user requirements, with lamp options to choose different light sources. Available in 60, 120, and 150cm widths, VeriVide Colour Assessment Cabinets provide a flexible solution for accurate color assessment.

Incorporate user-friendly features like servicing indicator, auto sequence, warm-up, power save and data storage.4 or 5 light source options Versions available for colour fastness testing and particulate testing both adhering to global standardsEnsure that you are using the best equipment available as they provide the best fluorescent D65 daylight simulator, with the highest Colour

Rendering Index (CRI), available. VeriVide Colour Assessment Cabinets products are known as light boxes, viewing booths, colour cabinets and others, depending on which industry or country they are serving in. They are used within a wide array of industry sectors throughout the world including textile and apparel, graphics, automotive, ceramics, cosmetics, pharmacology (CAC Particulate),

food, footwear, packaging and printing.Download the Datasheet below for more information or click 'VeriVide CAC Datasheet Here' to get in touch with colour experts.

VeriVide CAC Datasheet Here Features of VeriVide Colour Assessment Cabinets

• CAC 60, CAC 120 and CAC 150 accommodate 60, 120 and 150cm tubes respectively

VeriVide offers high-quality Colour Assessment Cabinets (CACs) such as the CAC 60-4, CAC 60-5, and CAC 120-4&5. These cabinets, originating from the UK, are reliable tools for visual evaluation in quality assurance, meeting national, international, and retailer standards. They effectively mitigate issues related to color assessment.VeriVide Colour Assessment Cabinets

High-quality visual evaluation tool for quality assurance. Adhering to national, international and retailer standards.Colour Assessment Cabinet's (CACs) reduce problems associated with assessing products or samples in different environments,be though geological or seasonal, offering a cost-effective method to ensure visual accuracy and product quality.

Color Light Box Enhance color precision with VeriVide's cutting-edge Colour Assessment

Cabinets. These cabinets are meticulously designed to ensure accurate color evaluation in various industries. Invest in VeriVide Colour Assessment Cabinets to elevate your color assessment process.

Enhance Color Precision with VeriVide's Cutting-Edge Assessment Cabinets, which meet or surpass ISO 3664 and BS 950 Part 1 international standards. The cabinets are adaptable to user requirements, with lamp options to choose different light sources. Available in 60, 120, and 150cm widths, VeriVide Colour Assessment Cabinets provide a flexible solution for accurate color assessment.

Incorporate user-friendly features like servicing indicator, auto sequence, warm-up, power save and data storage.4 or 5 light source options Versions available for colour fastness testing and particulate testing both adhering to global standardsEnsure that you are using the best equipment available as they provide the best fluorescent D65 daylight simulator, with the highest Colour

Rendering Index (CRI), available. VeriVide Colour Assessment Cabinets products are known as light boxes, viewing booths, colour cabinets and others, depending on which industry or country they are serving in. They are used within a wide array of industry sectors throughout the world including textile and apparel, graphics, automotive, ceramics, cosmetics, pharmacology (CAC Particulate),

food, footwear, packaging and printing.Download the Datasheet below for more information or click 'VeriVide CAC Datasheet Here' to get in touch with colour experts.

VeriVide CAC Datasheet Here Features of VeriVide Colour Assessment Cabinets

• CAC 60, CAC 120 and CAC 150 accommodate 60, 120 and 150cm tubes respectively

- Either 4 or 5 light sources available for each model including D65, D50, 840P15, F and UV - see Lamp Options.• Internal finishes in Munsell N5, Munsell N7 or Grey 5574 • Diffuser and/or dimmer options available Dimensions of VeriVide Colour Assessment Cabinets CAC 60-4 Dimensions (mm) Width Height Depth Overall 710 545 420

Products

Products

Martindale abrasion tester Updated

Martindale abrasion tester Updated